NaN / 0

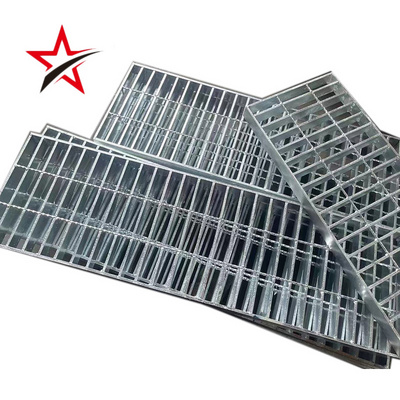

steel grating catwalk platform weight webforge grating

Get Latest Price

US$ 25.5

≥2 Pieces

US$ 24.6

≥100 Pieces

US$ 23.4

≥500 Pieces

US$ 22.3

≥1000 Pieces

Quick Details

Warranty:

1 Year

After-sale Service:

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Return and Replacement

Project Solution Capability:

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation

Application:

Outdoor

Product Details

steel grating catwalk platform weight webforge grating

Product Description

1. Brief Introduction of press locked steel gratings

With Press-Locked Grating the cross bars and bearing bars are notched and pressed together through a high pressure manufacturing process. The result is a bi-direction flush surface that assures a firm, rigid connection and makes it aesthetically appealing for architectural applications. It is available from stock in twp bearing bars heights, in plain or corrosion-resistant galvanized steel, or aluminum. A variety of other bar heights, bar spacings and materials is available by special order.

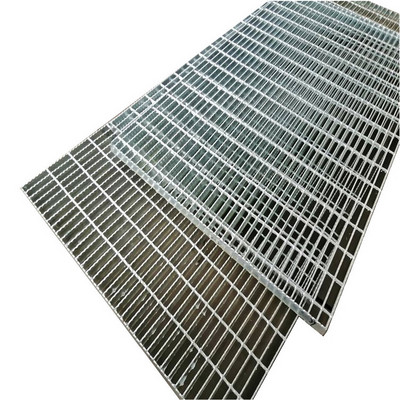

2. Bearing Bar Type:

| Steel grating | ||

| No. | Terms | Description |

| 1 | Material | Low carbon, mild steel, stainless |

| 2 | Material standard | GB700-88,ASTM(A36),BS4360(43A),AS3679 |

| 3 | Bearing bar size |

20*3,20*5,25*3,25*5,32*3,32*5,35*3,35*5,

40*3,40*5,45*5,50*3,50*5,55*5,60*5,65*5mm etc, |

| 4 | Bearing bar pitch | 15,20,25,30,33,35,38,40,50,60,80,90mm |

| 5 | Cross bar pitch | 24-200mm |

| 6 | Surface treatment | Untreated, Hot-dip galvanized, painting, stainless steel |

| 7 | Grating standard | YB/T4001.1-2007,ANSI/NAAMM(MBG531-88),BS4592-1987,AS1657-1985 |

| 8 | Bearing bar type | FLAT BAR / I-BAR / SERRATED BAR / SERRATED I-BAR |

| 9 | Application | Floor walkway,industrial platform,stair tread,metal ceiling |

| 10 | Feature | Fine appearance,anti-corrosive,simple installation,light weight, high load,anti-skid,Prevent dirt deposition,ventilation,anti-explosion |

| 11 | Payment terms | T/T,L/C |

| 12 | Package |

Pallets in containers packed by steel strap and worthy sea shipping, or according to customers' requirement |

| 13 | Product capacity | 15 days for a 20GP container |

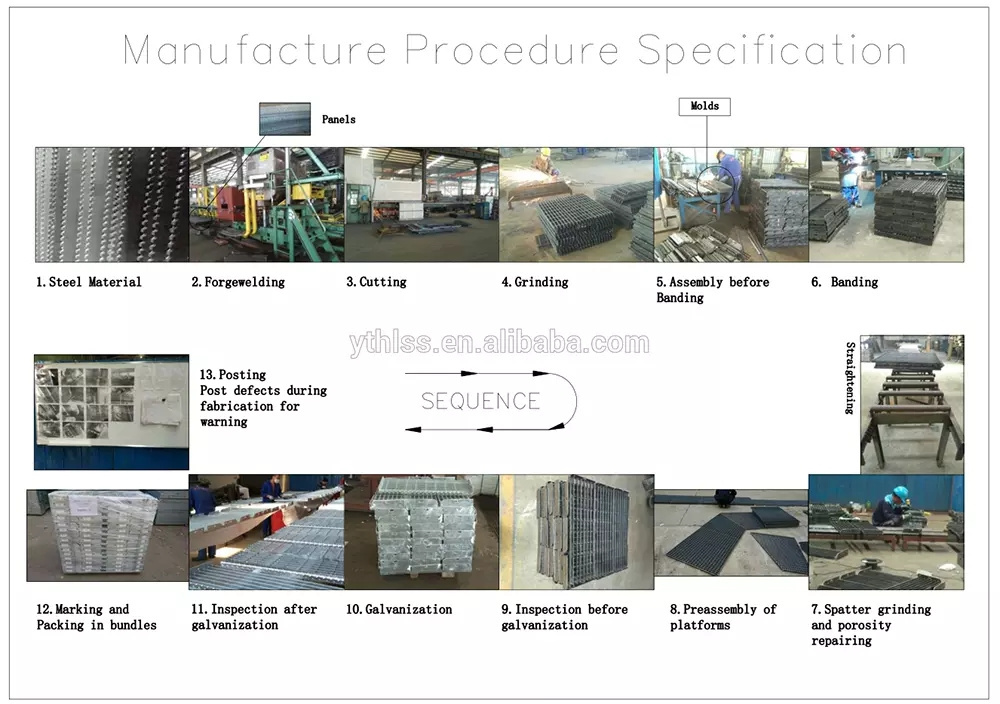

Productive process

Application

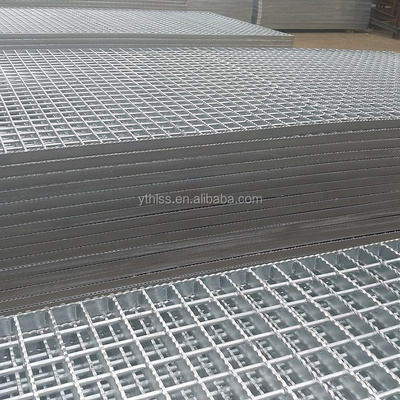

Application of Steel Floor Grating

1) It can be used in urben construction as drainage trench cover to drain water and keep ground dry.

2) The serrated steel gratings will be used in the port, parking lot, farmland and other places to be walk platform for pedestrian and vehicles access and passing.

3) Forge-Welding gratings also will be used for industry platform, power plant, water treatment industry, tower platform, etc.

4) Serrated steel gratings also be guardrail for garden, villa, balcony, highway, etc.

Our projects

Packaging & Shipping

Packing details:

1. stick the label on each grating, the panel number will be marked on the label.

2. insert the steel bracket through the gratings from bottom to the top to fix the package. if the grating panel's size is less than 1500mm*1000mm, 4 pcs steel brackets per package. if more than 1500mm*1000mm, the steel brackets will be added accordingly.

3. bundle the gratings with the PVC tape.

4.Attach a thermoplastic tag to each package. Accordingly to th tag, our clients can find each panel easily and swiftly.

5. wrap the gratings with plastic films.

FAQ

1. Quick response

We will reply our customer's inquiry ASAP within 24 hours.

2. Sample

Free sample is available if our customer are willing to undertake the courier fee.

3. Layout drawing or shop drawing

We can provide the layout drawing or shop drawings for our customers' project solution.

4. Inspection

Our factory supports all our customers or nominated third party to our factory for inspection.

In addition, we can provide the instant photos during the production.

5. Strong package

We will do our best to offer strong package to keep the goods safe and sound when our customer receive them.

6. Timely delivery

Our strong supply capacity can help us to deliver the goods in time.

7. After-sale service

We will track the goods' use condition. Not only providing the tech support, but the solution of goods' quality

Hot Searches