NaN / 0

1 ton 2 ton 4 ton 6 ton 8 ton coal biomass gas oil fired industrial package steam boiler

Get Latest Price

US$ 20000

≥1 Sets

Quick Details

Core Components:

serpentine tube, water pump, simons plc control

Steam Production:

Max. 3t/h

Place of Origin:

Zhejiang, China

Brand Name:

SFeng, SFeng

Product Details

Products Description

Biomass Coal Fired Steam Generator DZG

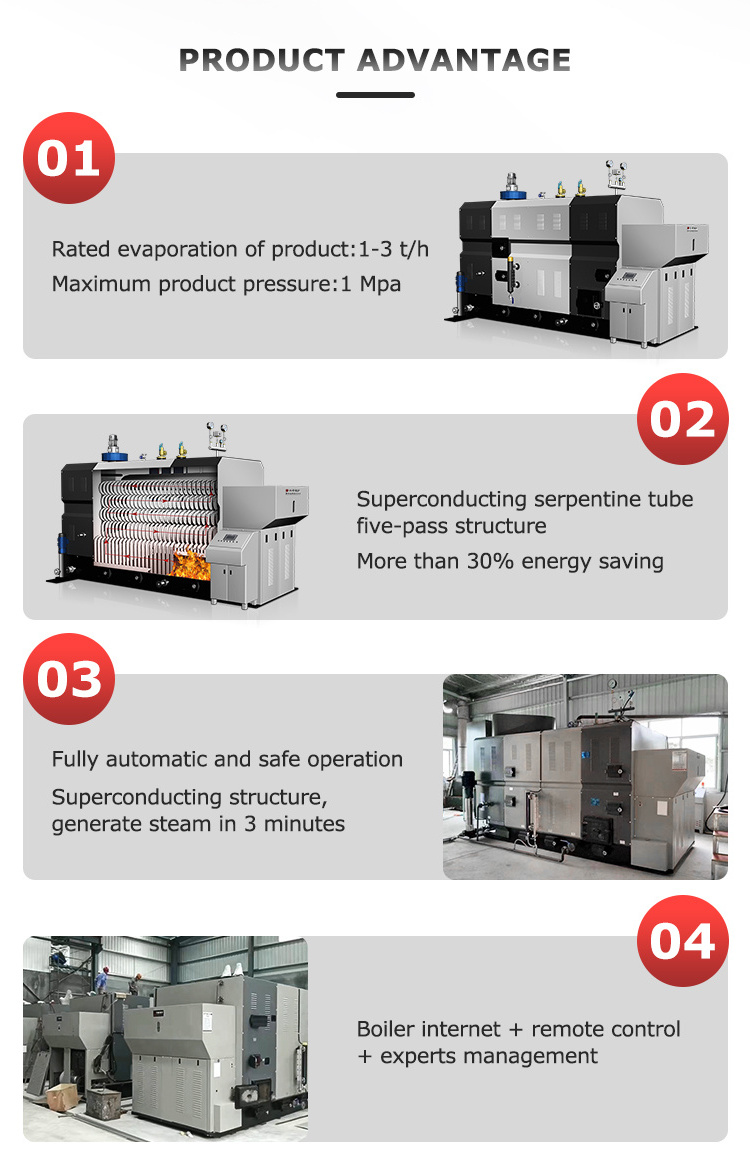

The SFeng DZG Series Biomass/coal fired steam generator has obtained multiple national patents. The equipment's unique superconducting serpentine tube five-pass structure increases the number of combustion returns compared to traditional water tube structures. It also enhances the contact area between the flue gas and the tube wall, thereby increasing the heating surface area. The flue gas is circulated through multiple returns after combustion and is equipped with a dual waste heat recovery system, enabling the flue gas to circulate again, thus improving the equipment's thermal efficiency and reducing fuel consumption by more than 30%.

Product Configuration

|

Model

|

Unit

|

DZG1.0-1.0-S

|

DZG1.2-1.0-S

|

DZG1.5-1.0-S

|

DZG2.0-1.0-S

|

|

Rated Steam Output

|

kg/h

|

1000

|

1200

|

1500

|

2000

|

|

Max Steam Pressure

|

Mpa

|

1.0

|

1.0

|

1.0

|

1.0

|

|

Max Steam Temperature

|

℃

|

184

|

184

|

184

|

184

|

|

Thermal Efficiency

|

%

|

90

|

90

|

90

|

90

|

|

Max Load Fuel Consumption(Biomass)

|

kg/h

|

158

|

190

|

237

|

316

|

|

Average Load Fuel Consumption(Biomass)

|

kg/h

|

110

|

132

|

166

|

221

|

|

Product Size

|

mm

|

4500 x 2000 x 3200

|

5000 x 2200 x 3200

|

6000 x 2400 x 3200

|

6500 x 2600 x 3400

|

|

Normal Level Water Capacity

|

L

|

29

|

29

|

29

|

29

|

|

Hopper Capacity

|

kg

|

350

|

370

|

400

|

500

|

|

Product Weight

|

t

|

6

|

7

|

9

|

12

|

|

Power Consumption

|

kw/h

|

10

|

12

|

15

|

20

|

|

Working Pressure

|

Mpa

|

0-1.0

|

0-1.0

|

0-1.0

|

0-1.0

|

FAQ

1. How can you get the best price quickly?

(1) We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

(2) Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

2. Why should you believe our boiler quality?

(1).Strength calculation report with applied materials information;

(2).100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3).100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4).Hydrostatic test: ensure the standard working pressure and safety;

(5).Third-party inspection report:By Jiangsu Boiler Inspection Institute;

(6).Passed ISO:9001 ,ISO14001,OHASA18001 and ASME(S and U) and A-class boiler certificate.

4. Quality warranty

The seller guarantee quality of the machines for a period of 12 months from the date of trial run finish, but not to exceed18

months from date on which the goods leave factory. If any parts (excluding easily damaging parts) are found defective in quality in the first year, the seller should replace free-of-cost.

5.Terms of payment

T/T 30% of total contract value as down payment;

T/T or L/C 70% of total contract value before delivery.

6.Claim

Any claims by the buyers regarding the machines shipped should be filed within 30 days after arrival of machines at the

destination specified in the relative B/L and supported by a survey report issued by a surveyor approved by the sellers, otherwise the sellers shall refuse to consider. Claims in respect of matters within responsibility of insurance company and/or shipping company will not be considered by the seller.

7. What is the using life of your boiler?

Normally the boiler is designed for 20 years life span, but with right operation and good maintenance, the boiler can be used for 20-25 years.

(1) We need to know the boiler capacity, the fuel you plan to use and the steam pressure you need, and then we can confirm the boiler model.

(2) Customer needs to provide us your name, email address and company name, and then we will send you price list immediately.And if you use whatsapp, skype or wechat, you can provide us your ID, it will be more convenient for our communication.

2. Why should you believe our boiler quality?

(1).Strength calculation report with applied materials information;

(2).100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

(3).100% X-ray inspection( (Longitudinal, transversal safety inspection)): ensure the quality of entire boiler;

(4).Hydrostatic test: ensure the standard working pressure and safety;

(5).Third-party inspection report:By Jiangsu Boiler Inspection Institute;

(6).Passed ISO:9001 ,ISO14001,OHASA18001 and ASME(S and U) and A-class boiler certificate.

4. Quality warranty

The seller guarantee quality of the machines for a period of 12 months from the date of trial run finish, but not to exceed18

months from date on which the goods leave factory. If any parts (excluding easily damaging parts) are found defective in quality in the first year, the seller should replace free-of-cost.

5.Terms of payment

T/T 30% of total contract value as down payment;

T/T or L/C 70% of total contract value before delivery.

6.Claim

Any claims by the buyers regarding the machines shipped should be filed within 30 days after arrival of machines at the

destination specified in the relative B/L and supported by a survey report issued by a surveyor approved by the sellers, otherwise the sellers shall refuse to consider. Claims in respect of matters within responsibility of insurance company and/or shipping company will not be considered by the seller.

7. What is the using life of your boiler?

Normally the boiler is designed for 20 years life span, but with right operation and good maintenance, the boiler can be used for 20-25 years.