NaN / 0

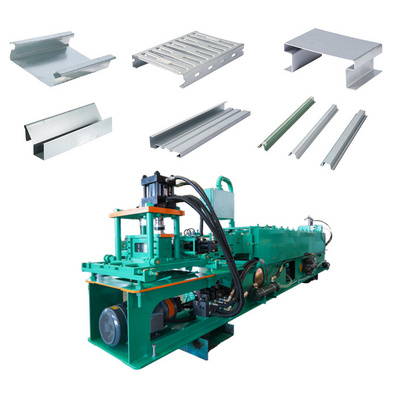

Low Noise Level Drip Edge Roll Forming Machine

Get Latest Price

US$ 50000

≥1 Sets

Quick Details

Type:

Down Spout Roll Forming Machine

Tile Type:

Metal Steel

Production Capacity:

15m/min(not include cutting time)

Place of Origin:

Jiangsu, China

Product Details

Application

Downspout / Downpipe / Roof Leader / Downcomer

Uses:

Collect roof rainwater and concentrate it on the rainwater pipes laid below the ground.

Usual format:

Common specifications for round tubes are 40mm, 50 mm, 75 mm, 90 mm, 110 mm, 150 mm, 200 mm, 250 mm, 315 mm, 400 mm, 500 mm, etc. Common specifications of the square tube are 80mm*55mm, 80mm*63mm, 80mm*100mm, etc.

Machine Details

Main Specification.

1. Suitable Material: Colored Steel plate, Galvanized steel

2. Width of the raw material: based on profile drawing

3. Thickness: 0.5-0.7mm

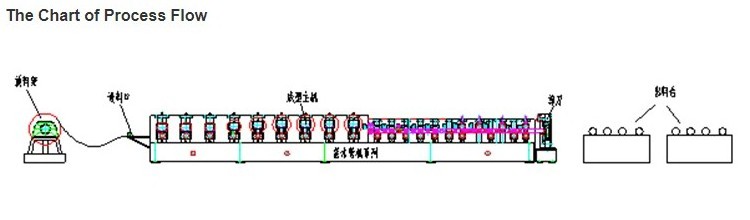

Manual Uncoiler-Roll Forming-Cutting-out table.

Machine Details

Servies

Saibo's Online Service.

Saibo Machinery Services Online gives you fast and easy online access to your Installed Base to order your SAIBO original spare parts and explore the Options & Upgrades relevant for your line.

It is a user-friendly interface, available 24/7, in 9 languages, and is your one-stop online shopping. Designed to make your life easier in your day to day business, it will help you to improve your line and maintain its performance.

SAIBO Services Online helps you:

1 - Machine running video

2 - Watch our factory online

3 - Supply a running line in your country, you can see the machine running directly.

Since we built your line, we have a comprehensive understanding of its design, and our engineering experts can analyze equipment and processes to determine how to strengthen performance. As new technologies and solutions are introduced to the market, we ensure that your production benefits accordingly, so you can stay on target in a changing, competitive marketplace.

Options & Upgrades helps you:

1 - Boost product quality

2 - Increase efficiency

3 - Reduce Total Cost of Ownership

4 - Future-proof your productivity

5 - Browse our online catalog

Packing & Delivery

About Saibo

Saibo Science & Technology - 20 Years Experience Manufacturer in Developing and Exporting.

Zhangjiagang City Saibo Science & Technology Co., Ltd. is a professional manufacturer specializing in the developing and exporting of different kind of high speed roll forming machine, Main use of our roll forming machine is for Solar Structures, PEB project and also for Cable tray, Guard Rail, Roofing Sheets, Floor Decking and all of the different kind purlin/channel which makes from GI/PPGI/PPGL/Aluminium/Aluminium alloy/SS . Our company, which is located in Zhangjiagang city, Jiangsu province, near Shanghai City with superior geographic position and convenient transportation.

We engaged in the steel structure industry in 20 years and devoted to developing some steel structure machines with professional technology and reasonable price, we supply the best machines for our new and regular customers. All of our technology team and marketing person all more than 10 years working. In particular, we are a leading exporter in the field of steel structure construction and can provide professional service, high quality, through design, and installation. Our goal is"

future by heartiness, faith leads to the world

".

International certification, National Certificate of equipment verification, and more than 30 invention patents are done in Saibo Machinery.

Verification Certificates of equipments: ISO9001:2001; CE Certificate , SGS , COC , TUV

National Certificate of equipment verification:standard organisation of Nigeria , CNCA certificate, Logo trademark registration, etc.

FAQ

Q1 : How to find SAIBO?

● Search Alibaba and Website find Saibo Machinery, suppliers, and manufacturers and not traders

● Visit the exhibition in different countries

● Send Saibo a request and tell your basic inquiry

● Saibo sales manager will reply to you in a short time and add instant chatting tool

Q2 : You are welcome to our factory at any time .

● If we can fulfill your request and you interested in our products, you may pay a visit to Saibo site

● The meaning of visiting supplier, because seeing is believing, Saibo with own manufacture and developed& research team, we can send you engineers and make sure to your after sales service.

Q3 : How to guarantee your funds to be safe and delivery to be on time ?

● Through the Alibaba letter guarantee service, it will ensure the on-time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

Q4 : See Saibo how to ensure the quality !

● To ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strict control by inspecting personnel.

● Each assembly is in charge by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

Q5 : The after-sale service of Saibo !

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by the standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factories to do the installation and training.

● Engineers, sales managers, and after-sales service managers will form an after-sales team, online and offline, to follow the customers' project.

Hot Searches