NaN / 0

BFL Tungsten Carbide Cutting Tool CNC V Groove Engraving milling Cutter 3D End Mill V Shape for wood PCB cutter

Get Latest Price

US$ 3

≥10 Pieces

US$ 2.25

≥100 Pieces

Quick Details

Material:

Carbide

Coating:

Altin, Tialn, Tisin, Tin, DLC,Nano, Diamond

Warranty:

N/A

Place of Origin:

Jiangsu, China

Product Details

Product Description

Product Parameters

|

HRC

|

HRC45/55/60/65

|

|

|

||

|

Coating Type

|

ALTIN /TIALN /TISIN /NACO /DLC /Diamond

|

|

|

||

|

OEM

|

√

|

|

|

||

|

Suitable For

|

All Kinds Matel Plastic Wood Acrylic and so on

|

|

|

||

Super Raw Material

|

Item Grade

|

HRC45

(YG10X )

|

HRC55

(YL10.2 & WF25)

|

HRC60

(Germany K44 &K40)

|

HRC65

(Sandvik H10F)

|

|

Details

|

Grain size 0.7um

Co10%

Flexural strength

3320N/mm2

|

Grain size 0.6um

Co10%

Flexural strength 4000N/mm2

|

Grain size 0.5um

Co12%

Flexural strength 4300N/mm2 |

Grain size 0.5um

Co10%

Flexural strength 4300N/mm2

|

Super Coating

|

Coating Classifying and Advantage

|

|

|

|

|

|

|||||

|

Item

|

Coating Type

|

AlTin

|

TiAlN

|

TiSiN

|

Naco

|

|||||

|

|

Hardness(HV)

|

3300

|

2800

|

4300

|

42(GPA)

|

|||||

|

|

Thickness(UM)

|

2.5-3

|

2.5-3

|

3

|

3

|

|||||

|

|

Oxidation Temp.(°C)

|

900

|

800

|

1000

|

1200

|

|||||

|

|

Friction Coefficient

|

0.35

|

0.3

|

0.25

|

0.4

|

|||||

|

|

Color

|

Black

|

Dark Purple

|

Copper

|

Blue

|

|||||

|

|

Advantages

|

High heat stability

|

Normally cutting

|

Suitable for heavy cutting, and high hardness cutting

|

For high precision cutting

|

|||||

|

|

|

Suitable for high speed, dry cutting

|

|

Suitable for cutting mould steel, stainless

steel |

Suitable for high hardness cutting, mould steel processing

|

|||||

|

|

|

Most suitable for carbide cutting tools, turning insert

|

|

|

|

|||||

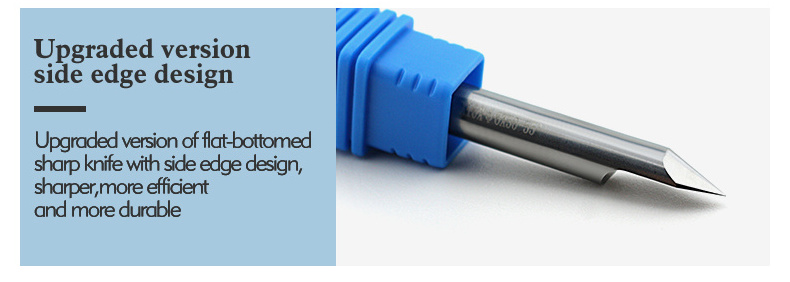

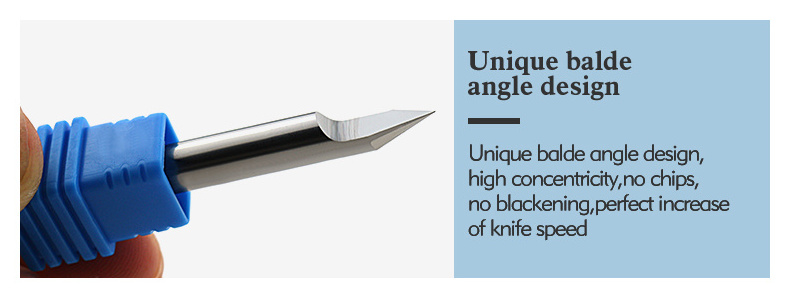

Detailed Images

Packing & Delivery

Q: Are you trading company or manufacturer ?

A: We are professional manufacturer,have more than 15 years experience in this field.

Q: Is free shipping possible?

A: We don't offer free shipping service,but we will give you some discount if you buy large quantity products.

And we have cooperation Express Companies,can offer you the best price of shipping cost.

Q: Can you send products to our Forwarder in China?

A: Yes,if you have Forwarder in China,we will glad to send products to him/her.

Q: Can you produce Special carbide Tools ?

A: Yes We can. From 2013 year. Our factory main market change from standard end mills to special tools. Special tools according to your drawing and sample.