NaN / 0

KINGISO High Frequency Timber Drying Machine/lumber Vacuum Dryers/wood Drying Kiln

Get Latest Price

US$ 28308

≥1 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

KINGISO Woodworking Machine

Machine Type:

High Frequency Timber Drying Machine

Weight (KG):

7000 KG

Product Details

Products Description

Product Introduction:

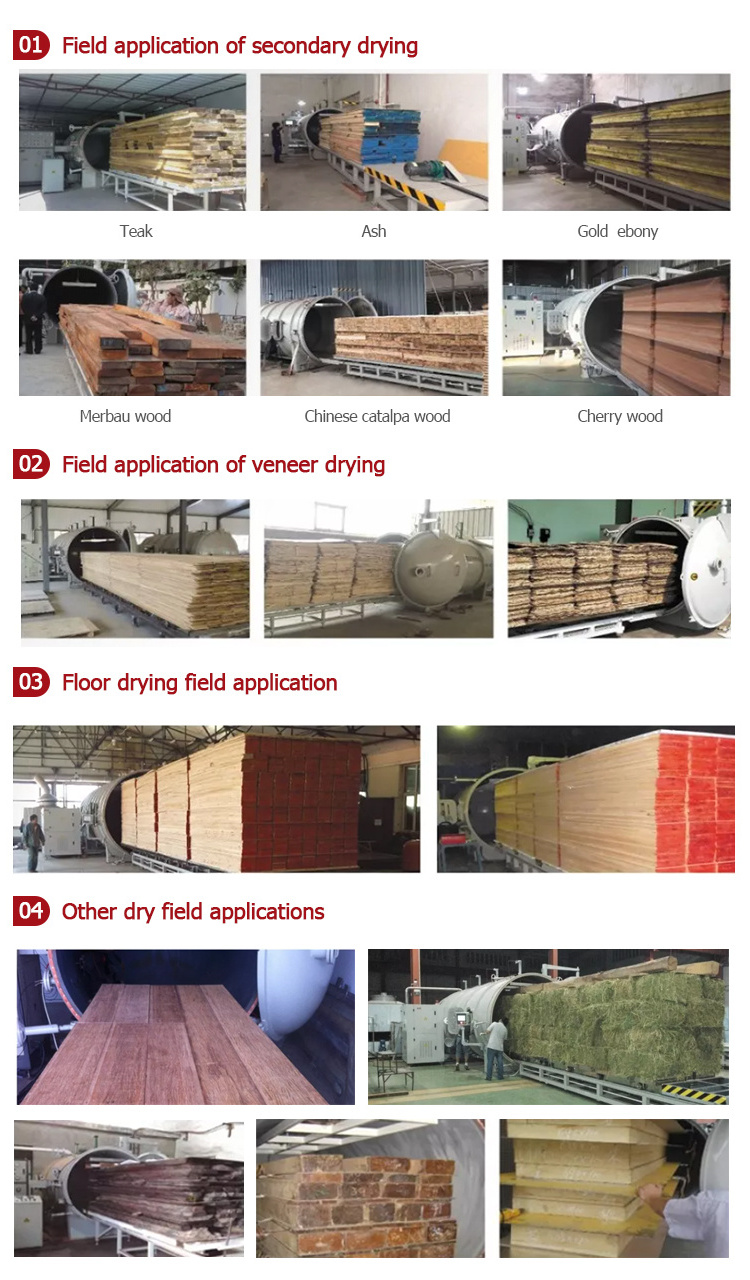

Adopts High frequency drying technology, inside and outside of wood timber is heated at the same time, uniform heating, high speed drying, short drying time and good quality.

Which can keep the timber nature color, meanwhile, the timber is aerated under the vacuum environment, non-cracking, especially applied for the thick and hard wood, or secondary drying for wood.

At the same time, it can dry floor semi-finished product, veneer, good flatness, simple operation. environmental protection, no boiler, which is effective to remove timber stress, and balance timber moisture content.

For hard wood (red wood) drying, thickness 6cm, or drying the moisture content 35%-50% padauk wood to get final moisture content 11%-13%, the drying time only needs 6 days, secondary drying only needs several hours.

|

Comparsion List for all kinds of drying method

|

|

|

|

|

|

|

|

|||||||

|

|

Traditional steam drying

|

Hot wind drying

|

Platen Vacuum drying

|

Microwave drying

|

Common High frequency drying

|

|

CNHF High frequency vacuum drying

|

|||||||

|

Drying speed

|

slow

|

slow

|

Slightly faster

|

Fast

|

Fast

|

|

Fast

|

|||||||

|

Working range

|

Timber thinkness 10-55mm

|

Timber thinkness 10-55mm

|

Thinner timber drying is suitable for panel of floor

|

Thinkness is less 20mm

|

It is suitable to dry veneer,thinner timber,hard wood or thinker timber(especially for red wood) in final drying and secondary

drying |

|

|

|||||||

|

Loading method

|

Cumbersome loading it needs put baffle between wood timbers for air convection

|

Cumbersome loading it needs put baffle between wood timbers for air convection

|

More cumbersome loading

|

Simple Loading .but it has requirments for loading position,or the wood will be dried uniformly.

|

Very simple. Directly stack timber on feed device,ni need baffle.

|

|

|

|||||||

|

Flatness after drying

|

Bad,easy deformation and bend

|

Bad,easy deformation and bend

|

Good,Good flatness by hot platen

|

Better

|

Best.The timber will not happen deformation and bend under the hydraulic platen press timber tightly

|

|

|

|||||||

|

Uniform moisture content after drying

|

Little

|

Much

|

Little

|

Less

|

Least

|

|

|

|||||||

|

Drying cost

|

Low cost.But it is high cost for drying hard and thicker wood.

|

Low cost.But it is high cost for drying hard and thicker wood.

|

Higher

|

Highest

|

Higher.but low cost for hard wood,thicker wood and secondary drying for wood.

|

|

|

|||||||

|

Uniform moisture content after drying

|

Good

|

Worse than traditional steam drying

|

Good

|

Commom

|

Bad

|

Better

|

|

|||||||

|

Operation

|

Complicated operation and works need professional training

|

Complicated operation and works need professional training

|

Complicated operation and works need professional training

|

Simple

|

Simple

|

Simple

|

|

|||||||

Related Products

Product Packaging

Hot Searches