NaN / 0

Toption supply lab Glass Fraction Distillation Column With Factory Price

Get Latest Price

US$ 2600

≥1 Pieces

US$ 2550

≥2 Pieces

US$ 2500

≥3 Pieces

Quick Details

Place of Origin:

Shaanxi, China

Brand Name:

TOPTION

Voltage:

220V

Power:

300W

Product Details

Products Description

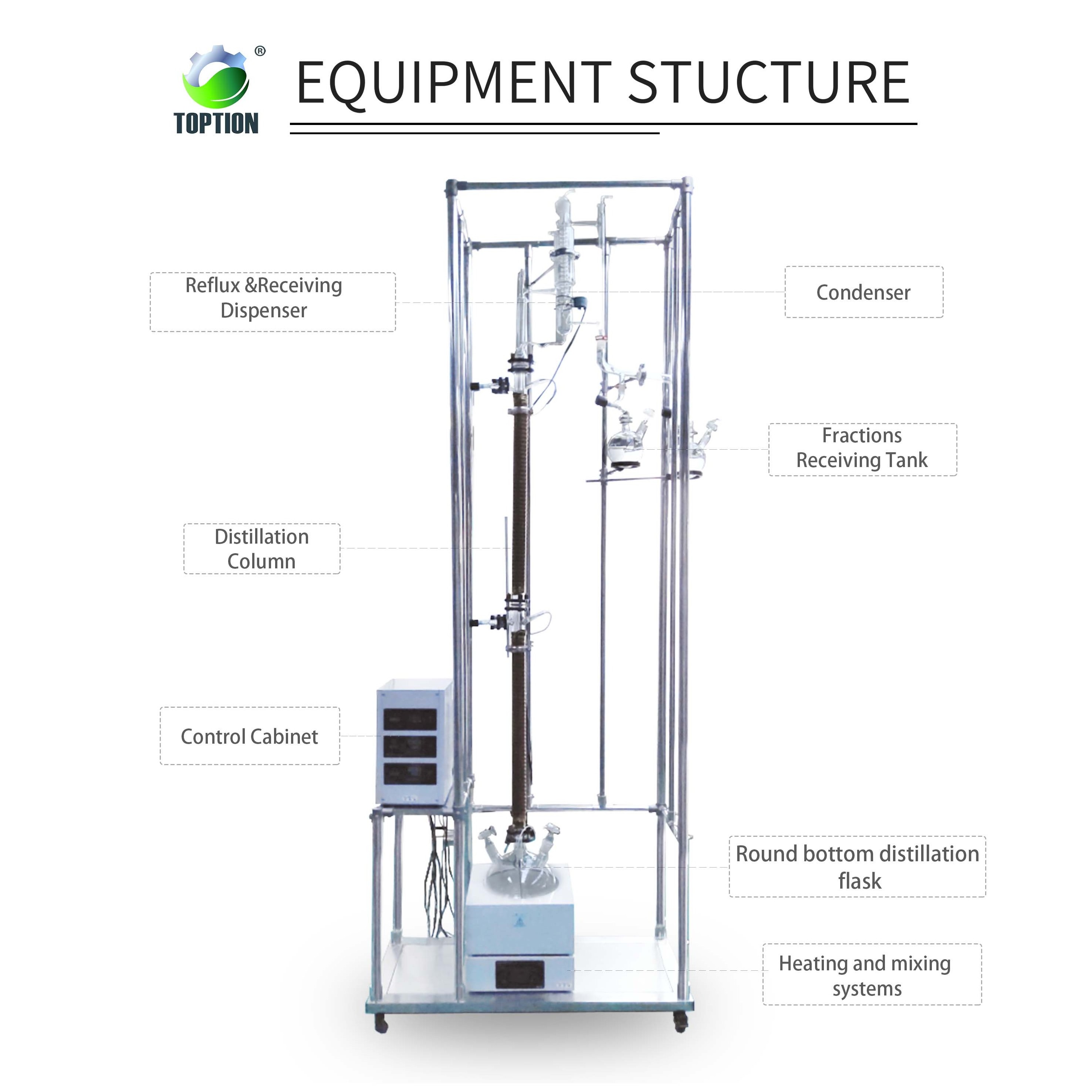

1-50L Essential Oil Distillation Column Industrial Chemical Fractional Distillation Glass Rectification

Fractional distillation is a technique used to purify solvents, chemicals, natural products, petroleum, biodiesel, crude oil and other materials.

Best Solution for Separating Components of Very Close Boiling Points High Purity Distillates Can Be Made Through Repeated Distillation in Distillation Column Various Fractions Can Be Received By Batch Distillation.

specification

|

Product number

|

|

TOPR-1L

|

TOPR-2L

|

TOPR-3L

|

TOPR-5L

|

||||

|

material capacity

|

|

1L

|

2L

|

3L

|

5L

|

||||

|

glass material

|

|

High borosilicate GG17

|

|

|

|

||||

|

Distillation Reactor

|

Number of openings

|

Distillation column head

|

|

|

|

||||

|

|

|

Inlet

|

|

|

|

||||

|

|

|

Temperature measuring port

|

|

|

|

||||

|

|

|

Backup port

|

|

|

|

||||

|

|

Stirring method

|

Magnetic stirring

|

|

|

|

||||

|

|

Stirring power

|

40W brushless DC motor

|

|

|

|

||||

|

|

Stirring control

|

LCD screen

|

|

|

|

||||

|

|

Stirring speed

|

20-1200rpm

|

|

|

|

||||

|

|

Heating method

|

Smart LCD Magnetic Stirring Heating Mantle

(550W / 650W / 750W / 1100W) |

|

|

|

||||

|

|

Operating temperature

|

Room temperature -250 ℃

|

|

|

|

||||

|

Precision Electric Heating Distillation Column

|

Tower section size

|

φ 25*700mm

|

|

φ 30*800mm

|

|

||||

|

|

Heating method

|

Interlayer built-in electric heating wire heating

|

|

|

|

||||

|

|

Heating power

|

300W

|

|

500W

|

|

||||

|

|

Heating controller

|

Intelligent digital display PID temperature control

|

|

|

|

||||

|

|

Operating temperature

|

Room temperature -200 ℃

|

|

|

|

||||

|

|

Features

|

Maintain the temperature gradient of the rectification column to achieve fractional distillation of components with different

boiling points |

|

|

|

||||

|

Precision distillation head

|

Funnel with rocking magnet

|

The rectifying head is cooled by a jacket and a serpentine double condenser, and the reflux ratio is controlled by changing the

swing position of the triangular funnel of the magnet under electromagnetic attraction, which is easy to clean |

|

|

|

||||

|

|

Reflux Ratio Controller

|

The device uses intelligent instruments to control the opening and closing of the electromagnetic to control the return flow. The

return flow can be adjusted arbitrarily, and the ratio of the return flow to the output can be accurately adjusted. The control range is 1:99-99:1 |

|

|

|

||||

|

Receiving bottle

|

|

500ml

|

1L

|

2L

|

|

||||

|

Vacuum tube

|

|

4 meters

|

|

|

|

||||

|

Vacuum grease

|

|

1 copy

|

|

|

|

||||

|

Instrument fixture

|

|

1 set

|

|

|

|

||||

|

Mobile casters

|

|

4 with brakes

|

|

|

|

||||

|

Machine frame

|

|

Stainless steel 304 tic-tac-toe frame

|

|

|

|

||||

Detailed Images

Product advantages

Certifications

Our Company

Exhibition

Hot Sale

FAQ

1. How can I choose the suitable one?

Dear customer, please tell us your detailed requirements by mail or online, we will recommend the suitable one as your

request.

2. How can I pay?

Dear customer, we accept many payment term, such as T/T, Western Union...

3. When I receive it after pay?

Dear customer, normal models can be delivered with 7-9 days, please contact us to check transport time to your address.

4. How to deliver?

Dear customer, we can send by Express, by Sea and by Air.

Dear customer, please tell us your detailed requirements by mail or online, we will recommend the suitable one as your

request.

2. How can I pay?

Dear customer, we accept many payment term, such as T/T, Western Union...

3. When I receive it after pay?

Dear customer, normal models can be delivered with 7-9 days, please contact us to check transport time to your address.

4. How to deliver?

Dear customer, we can send by Express, by Sea and by Air.

5. Is will be broken during transport?

Dear customer, please do not worry, we do standard export package.

6. What should I do if I do not know how to use?

Dear customer, please do not worry, manual user will be sent together, you can also contact us with more technological

support.

7. What should I do if some parts broken?

Dear customer, please do not worry, we have 12months warranty except wear parts. You can also buy parts from us after

12months.

Dear customer, please do not worry, we do standard export package.

6. What should I do if I do not know how to use?

Dear customer, please do not worry, manual user will be sent together, you can also contact us with more technological

support.

7. What should I do if some parts broken?

Dear customer, please do not worry, we have 12months warranty except wear parts. You can also buy parts from us after

12months.

Hot Searches