NaN / 0

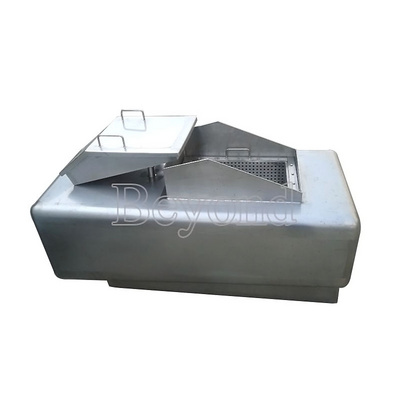

Factory Customized sus304 sus316l milk can milk tank stainless steel 304

Get Latest Price

US$ 500

≥1 Pieces

Quick Details

Marketing Type:

New Product 2023

Place of Origin:

Shanghai, China

Brand Name:

Beyond

Voltage:

customized

Product Details

Factory Customized sus304 sus316l milk receiving tank machine

The dairy receiving tank is an important equipment in dairy processing plants, used to receive and store raw milk. The following is a detailed introduction to the dairy receiving tank:

1. Function:

The main function of a dairy receiving tank is to receive, store, and process raw milk. It is the primary step before raw milk enters the dairy processing production line. The receiving tank ensures the quality and safety of raw milk during the manufacturing process by providing suitable storage conditions.

2. Structure:

Dairy receiving tanks are usually made of stainless steel to ensure compliance with hygiene standards and food safety requirements. It typically includes the following main components:

-Receiving tank: a container used to hold raw milk, with a certain capacity and shape to meet production needs.

-Feed inlet: used to connect the conveying pipeline system and guide the raw milk into the receiving tank.

-Switching valve: used to control the flow of milk and can be opened or closed as needed.

-Temperature sensor: used to monitor the temperature of milk to ensure compliance with processing requirements.

-Mixer: optional component used to stir milk, preventing it from layering and settling.

3. Operation process:

The operation process of a dairy product receiving tank usually includes the following steps:

-Cleaning and disinfection: Before receiving a new batch of milk, the receiving tank must be thoroughly cleaned and disinfected to prevent cross contamination.

-Receiving milk: Open the feeding port and valve, and guide the raw milk into the receiving tank. Meanwhile, the temperature of the milk is monitored through temperature sensors.

-Storing milk: Once the milk enters the receiving tank, the valve can be closed and the milk can be stored. The receiving tank provides appropriate storage conditions, such as temperature control and stirring, to ensure the quality and safety of milk.

-Filtering and processing: As needed, stored milk can be filtered and processed to remove impurities and improve quality.

4. Precautions:

When using a dairy receiving tank, the following precautions should be taken:

-Strictly follow hygiene standards and food safety regulations to ensure the cleanliness and disinfection of the receiving tank and its supporting equipment.

-Regularly inspect the receiving tank to ensure its normal operation and perform necessary maintenance and repairs.

-Milk should be processed as soon as possible after entering the receiving tank to avoid quality degradation and safety issues.

-Regularly clean the sediment and residue in the receiving tank.

Summary: Dairy receiving tanks play an important role in dairy processing plants, ensuring product quality and safety by receiving, storing, and processing raw milk. Proper use and maintenance of dairy receiving tanks can help ensure the smooth progress of dairy processing.

Product Description

High quality newly manufactured Stainless steel tank ,

1. Material : SUS304 and SUS316 stainless steel available, made according to client requirement.

2. Working performance: Good and easy to maintenance.

3. Milk receiving tank with good looking, simple structure and easy cleaness; It is matched with the milk weighing equipment; This equioment can designed according the different requirements of the customer, the outlet position can be designed according the flow and the layout of the whole plant.

Hot Searches