NaN / 0

PVC Gypsum Ceiling Board Vinyl Colorful Gypsum Tiles

Get Latest Price

US$ 0.55

≥100 Square meters

US$ 0.52

≥1000 Square meters

US$ 0.45

≥3000 Square meters

US$ 0.33

≥10000 Square meters

Quick Details

Warranty:

More than 5 years

After-sale Service:

Online technical support, Onsite Installation, Onsite Training, Onsite Inspection, Free spare parts, Return and Replacement

Project Solution Capability:

graphic design, 3D model design, total solution for projects

Application:

Hotel

Product Details

Contact us

Products Description

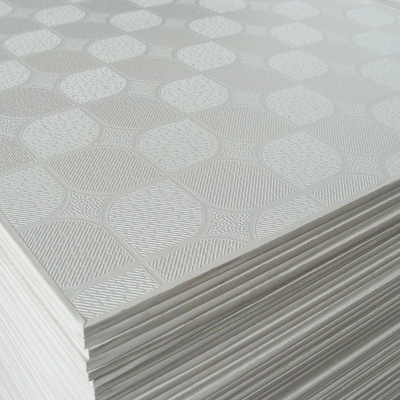

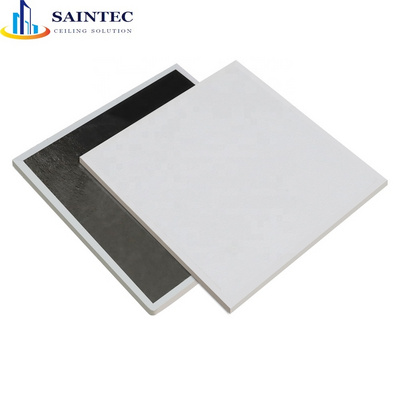

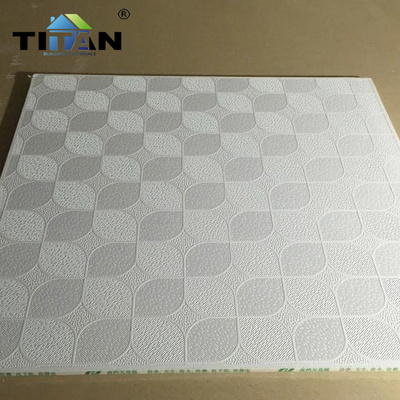

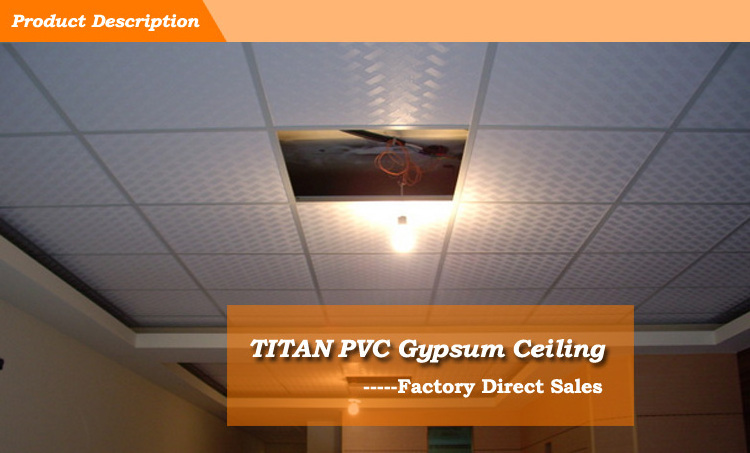

PVC Laminated Gypsum Ceiling Tile or Vinyl Laminated Gypsum Ceiling Tile, which is made of incombustible gypsum, free of any harmful substances, and fulfills all current national and international requirements. The ceiling tiles are laminated with an anti-static PVC film on the front side and metalized pet foil on the backside. These give the ceiling tiles a superior, maintenance-free finish along with additional thermal insulation properties. It can be used in areas requiring clean, dust-free interior such as computer rooms, food processing electronics and pharmaceutical companies.

Advantage

1. Ceiling surface covered by decorative vinyl already, no need further decoration.

2. Easy installation, maintenance, wipe-clean vinyl surface.

3. Good light reflection.

4. Integrated biocide version available.

5. A non-combustible gypsum core assures fire safety with 1 1/2- and 2-hour fire rating achievable depending on installation.

6. Install easily in standard exposed grid systems.

7. The sturdy white vinyl laminate eliminates additional finishing.

8. The product shall be maintained at a temperature not to exceed 104° Fahrenheit (40° Centigrade) and not exceed 90% relative humidity prior to, during and after installation.

Specification

1. For metric girds: 600x600mm(cut size: 595x595mm)

600x1200mm(cut size: 595x1195mm)

2. For imperial grids: 2′ x 2′(cut size: 603x603mm)

2′ x 4′(cut size: 603x1213mm)

3. Edge: Square

4. Available packing: 6pcs/ctn, 8pcs/ctn, 10pcs/ctn

5. Available thickness: 7.0mm, 7.5mm, 8.0mm, 9.0mm, 12.0mm

6. Moisture rate: ≤2%

7. Saging resistant properties: ≤3mm

8. Thermal conductivity: 0.16w/mK

9. Humidity resist: Resistant to 95% humidity and standing water

10. Light reflectance: 0.75

|

Width(mm)

|

Length(mm)

|

Thickness(mm)

|

Edge

|

|||

|

600 mm

|

600 / 1200 mm

|

7.0 / 7.5 / 8.0/ 9.0 /12.0

|

Covered / Non-covered

|

|||

|

603 mm

|

603 / 1206 mm

|

|

|

|||

|

605 mm

|

605 / 1210 mm

|

|

|

|||

|

Metric / Imperial Sizes Available

|

|

|

|

|||

Related Products

Production Process

Product packaging

|

Thickness

|

KGS/PCS

|

PCS/CTN

|

KGS/CTN

|

M2/20GP

|

CTNS/20GP

|

PCS/20GP

|

TONS/20GP

|

|

7.0

|

2.08

|

8

|

16.60

|

4150

|

1422

|

11000

|

22.88

|

|

8.0

|

2.22

|

8

|

17.80

|

3850

|

1337

|

10696

|

23.80

|

|

8.5

|

2.30

|

8

|

18.40

|

3600

|

1250

|

10000

|

23.00

|

|

9.0

|

2.48

|

8

|

19.84

|

3200

|

1111

|

8888

|

22.04

|

|

12.0

|

3.26

|

8

|

19.60

|

2274

|

1053

|

6496

|

20.60

|

Installation Instructions

Application

Hot Searches