NaN / 0

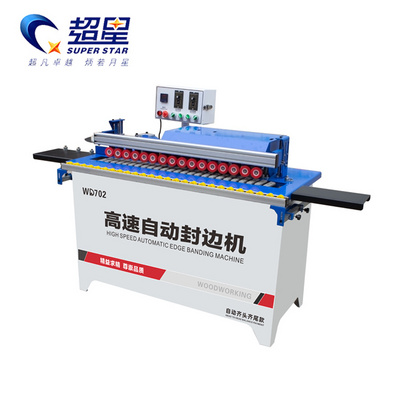

Edge Banding Machine Woodworking Edge Banding Machine 45 Degree Edge Bander Roller Pressure For Wood

Get Latest Price

US$ 1980

≥1 Sets

US$ 1036

≥6 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

SAMET

Voltage:

380 V(220V,400V,415V,440V etc)

Dimension(L*W*H):

4500*900*1500mm

Product Details

Products Description

This machine is suitable for linear edge banding of solid wood board, fiberboard, creative board and other board workpieces. The edge banding materials can be solid wood strip, PVC, melamine, veneer, etc.

*

Using imported quality engines and electric components.

*

Serialized products, a wide range of selection by customers

*

High precision and effciency.

IF YOU WANT TO KNOW MORE ,PLEASE SEND INQUIRY

Details Images

|

Panel Feed Speed(m/min)

|

15m/min

|

|

Edge Thickness

|

0.4-3mm

|

|

Edge Width

|

10-50mm

|

|

Edge banding height

|

12-60mm

|

|

Panel thickness

|

8-30mm

|

|

Mini work Panel Width

|

> 80mm

|

|

Mini work Panel Length

|

>120 Mm

|

|

Heating power of plastic box

|

1.5kw

|

|

Plate preheating power

|

0.37KW

|

|

End cutting motor power

|

0.55kw * 2 1200r / min200HZ

|

|

Transmission motor power

|

2.2KW

|

|

Polishing motor power

|

0.18kw*2 1400r / min 300Hz

|

|

Fine trimming motor power

|

0.75kw*2 1800r / min 300Hz

|

|

Total power

|

10kw

|

|

Air pressure

|

0.9MPA

|

|

Machine weight

|

2200KG

|

|

Machine size

|

4500*900*1500mm

|

Gluing

The glue pot is heated to melt the solid glue, and the screw structure is used to send glue, so that the plate is coated evenly.

Control Panel

Trim equipment with double trim-bladesworks on the waved effect that is caused byprecise dimersicen saw

Front And End Cutter

It is composed of front endtrimming and back end trimming. It is controlled byTaiwan Yadeke solenoid valve,1t has a unique function of endtrimming and plate collisionprotection.

mechanism used for and aestheticrepairing the excess edge materialsAdoptautomatic tracking and high-frequencymotor fast cutting structure to ensure thetrimming plates smoothly

Scraping

Use the cotton polishingwheel to clean the processed plate, and make the edgesealing end more smoothand clean by polishing.

suffing and clean

The buffing device adopt the board processed by cotton polishing wheel,byend-polishing to make a more smooth surface。

Application

Our Services

1.1 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an cost price when you need replacement.

5.24 hours on line service each day, free technical support.

6.Machine has been adjusted before delivery.

1.1 years quality guaranty, the machine with main parts(excluding the consumables) shall be changed free of charge if there is any problem during the warranty period.

2.Lifetime maintenance free of charge.

3.Free training course at our plant.

4.We will provide the consumable parts at an cost price when you need replacement.

5.24 hours on line service each day, free technical support.

6.Machine has been adjusted before delivery.

Product packaging

Hot Searches