NaN / 0

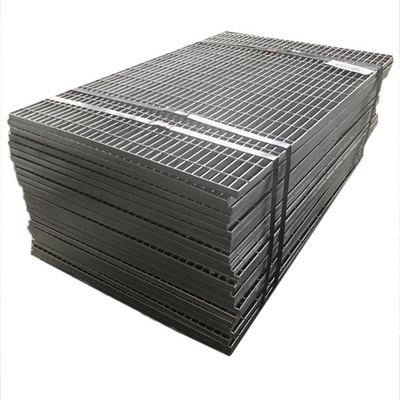

XINZHOU Hot dip HDG Heavy Duty Galvanised iron Bar Galvanized Steel Grating

Get Latest Price

US$ 39

≥50 Square meters

US$ 37

≥149 Square meters

US$ 35

≥300 Square meters

Quick Details

Warranty:

1 Year

After-sale Service:

Other

Project Solution Capability:

total solution for projects

Application:

Office Building

Product Details

Main Product

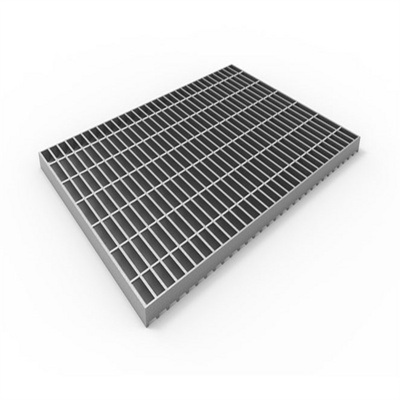

Steel bar grating with high strength and firm structure is made up of carbon steel, aluminum steel, or stainless steel. According to the manufacturing methods, it can be divided into four types: welded, press-locked, swage-locked, and riveted gratings.

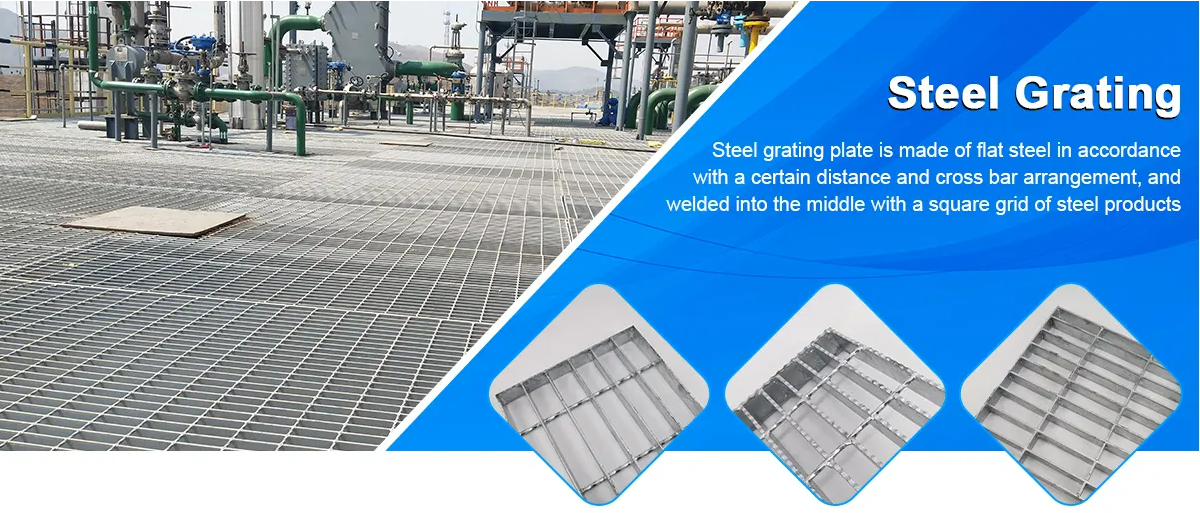

According to the surface shapes, it can be divided into smooth and serrated gratings. With various styles and sizes for choice, steel gratings are widely used in everyday life, such as stair treads, walkways, platforms, floors, various covers, wheeled equipment, security screens, heavy-duty constructions, and so on.

According to the surface shapes, it can be divided into smooth and serrated gratings. With various styles and sizes for choice, steel gratings are widely used in everyday life, such as stair treads, walkways, platforms, floors, various covers, wheeled equipment, security screens, heavy-duty constructions, and so on.

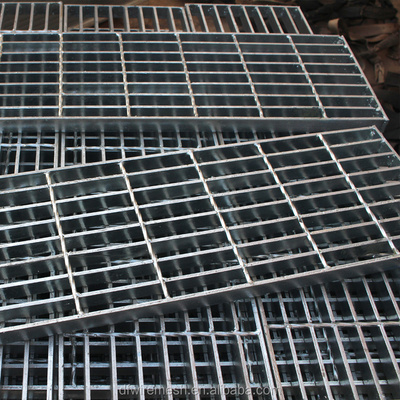

Welded Grating:

The most commonly used and economical design suitablefor most industrial applications. Manufactured by welding the bearing bar and cross bar intersection, typically with automated forge welding equipment or professional manual welding. Available in carbon steel or stainless steel.

D

ovetail Pressure Locked:

Insert the cross bar into the pre-punched bearing bar and hydraulically deform it to lock it in place. The cross bar here is usually a straight plate shaped like a bearing bar.

Swaged Pressure Locked:

Assembled by inserting pre-punched bearing and cross bars into an "egg-crate" configuration and deforming the cross bars under intense hydraulic pressure. Available in all materials and ideal for architectural and ornamental applications.

Welded Swaged Pressure Locked:

It is an upgraded version of the swaged pressure locked.dEach intersection is manually welded once to make it stronger and can withstand more loads.

Surface Treatment

----------------------------------------------------------------------------------------------------------------------------------

We provide four finishes for anti-corrosion treatment of carbon steel bar grating:

* Black / Bare Steel: No finish, life is very short, but the price is the cheapest.

* Painted Coat: The anti-rust effect is general and can be any color.

* Electro-galvanized: A small amount of zinc coating, easy to cause slight corrosion in humid environment.

* Hot-dip galvanized: The most commonly used method to provide the best anti-rust effect, strictly in accordance with ASTM A123 or GB/T 13912-2002.

----------------------------------------------------------------------------------------------------------------------------------

We provide four finishes for anti-corrosion treatment of carbon steel bar grating:

* Black / Bare Steel: No finish, life is very short, but the price is the cheapest.

* Painted Coat: The anti-rust effect is general and can be any color.

* Electro-galvanized: A small amount of zinc coating, easy to cause slight corrosion in humid environment.

* Hot-dip galvanized: The most commonly used method to provide the best anti-rust effect, strictly in accordance with ASTM A123 or GB/T 13912-2002.

Due to discoloration during welding and manufacturing, stainless steel bar grating usually requires a second cleaning:

* Stainless steel pickling passivation: Soak the entire stainless steel grating in the stainless steel pickling passivation

solution, provide a uniform silver-white matte surface.

* Stainless steel electrolytic polishing: The stainless steel grating is immersed in the electrolytic solution that is energized

and heated to 75 degrees for 1-3 minutes, can obtain a bright stainless steel surface.

* Stainless steel pickling passivation: Soak the entire stainless steel grating in the stainless steel pickling passivation

solution, provide a uniform silver-white matte surface.

* Stainless steel electrolytic polishing: The stainless steel grating is immersed in the electrolytic solution that is energized

and heated to 75 degrees for 1-3 minutes, can obtain a bright stainless steel surface.

I

nstallation of steel grating

Packing & Delivery

Cooperation Case

Factory

Our Team

Contact Us

Hot Searches