NaN / 0

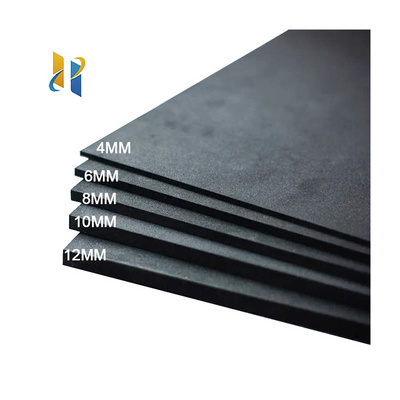

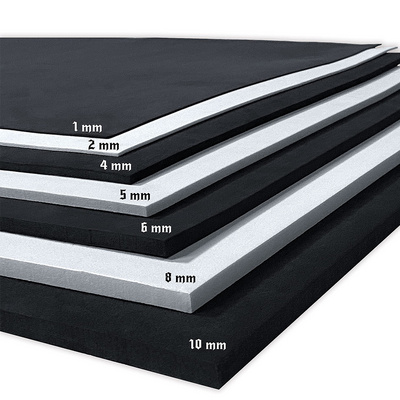

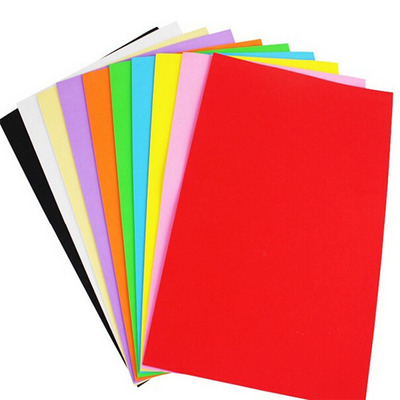

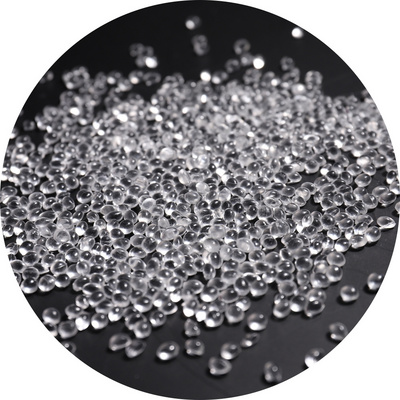

High Quality EVA foam 40mm 6mm eva foam 50mm bulk eva craft foam material with good price

Get Latest Price

US$ 1940

≥25 Tons

US$ 1900

≥1000 Tons

US$ 1350

≥1000000 Tons

Quick Details

color:

white

Shape:

granule

Place of Origin:

Hebei, China

Brand Name:

CHIJIANG

Product Details

Specification

Ethylene vinyl acetate copolymer, abbreviated as EVA. The general content of vinyl acetate (VA) is between 5% and 40%. Compared with polyethylene PE, EVA reduces high crystallinity, improves toughness, impact resistance, filler solubility, and thermal sealing performance by introducing vinyl acetate monomers into its molecular chain. It is widely used in fields such as foaming shoe materials, functional greenhouse films, packaging molds, hot melt adhesives, wires and cables, and toys.

Features:

Water resistance: closed cell structure, non absorbent, moisture-proof, and good water resistance, Corrosion resistance: resistant to chemicals such as seawater, oil, acid, alkali, etc., antibacterial, non-toxic, odorless, and pollution- free, Processability: No joints, and easy to perform processing such as hot pressing, cutting, gluing, and bonding,

Anti vibration: High resilience and tension resistance, high toughness, and excellent shock and cushioning performance,

Thermal insulation: Excellent insulation, cold resistance, and low temperature performance, resistant to severe cold and exposure to sunlight,Sound insulation: Closed bubble holes, good sound insulation effect.

Features:

Water resistance: closed cell structure, non absorbent, moisture-proof, and good water resistance, Corrosion resistance: resistant to chemicals such as seawater, oil, acid, alkali, etc., antibacterial, non-toxic, odorless, and pollution- free, Processability: No joints, and easy to perform processing such as hot pressing, cutting, gluing, and bonding,

Anti vibration: High resilience and tension resistance, high toughness, and excellent shock and cushioning performance,

Thermal insulation: Excellent insulation, cold resistance, and low temperature performance, resistant to severe cold and exposure to sunlight,Sound insulation: Closed bubble holes, good sound insulation effect.

Product Paramenters

EVA 16%

|

PROPERTIES

|

TEST METHOD

|

UNIT

|

Data

|

|

VA Content

|

|

%

|

16.0

|

|

Density

|

ASTM D1505

|

g/cm³

|

0.937

|

|

Melt Index MI2.16

|

ASTM D1238

|

g/10min

|

1.5

|

|

Tensile Strength (Break)

|

ASTM D638

|

Kg/c㎡

|

170

|

|

Elongation at break

|

ASTM D638

|

%

|

700

|

|

Melting point

|

ASTM D-3418

|

ºC

|

89

|

|

Hardness

|

ASTM D2240

|

Shore D

|

37

|

EVA 18%

|

PROPERTIES

|

TEST METHOD

|

UNIT

|

Data

|

|

VA Content

|

USI

|

%

|

18

|

|

Density

|

ASTM D792

|

g/cm³

|

0.939

|

|

Melt Index

|

ASTM D1238

|

g/10min

|

2.5

|

|

Tensile Strength(Molded)(Break)

|

ASTM D638

|

kg/c㎡

|

180

|

|

Ultimate elongation(Molded)

|

ASTM D638

|

%

|

750

|

|

Low Temperature Brittleness

|

ASTM D746

|

ºC/F50

|

<-76

|

|

Vicat Softening Point

|

ASTM D1525

|

ºC

|

64

|

|

Melt Point

|

ASTM D3418

|

ºC

|

86

|

|

Hardness

|

ASTM D2240

|

(Shore D)

|

36

|

EVA 28%

|

PROPERTIES

|

TEST METHOD

|

UNIT

|

Data

|

|

VA Content

|

|

%

|

28.0

|

|

Density

|

ASTM D1505

|

g/cm³

|

0.954

|

|

Melt Index MI2.16

|

ASTM D1238

|

g/10min

|

15

|

|

Tensile Strength (Break)

|

ASTM D638

|

Kg/c㎡

|

80

|

|

Elongation at break

|

ASTM D638

|

%

|

>800

|

|

Melting point

|

ASTM D-3418

|

ºC

|

69

|

|

Hardness

|

ASTM D2240

|

Shore D

|

20

|

Prouduct Application

1. EVA with a VA content below 5% mainly produces films, wires and cables, LDPE modifiers, adhesives, etc;

2. EVA with a VA content of 5% to 10%, products such as elastic film, injection molding, and foam products;

3. EVA with a VA content of 20%~28%, mainly used for hot melt adhesives and coating products;

4. EVA with a VA content of 28% -33%, photovoltaic materials, solar cell adhesives, etc;

5. EVA with a VA content of 38% -40%, adhesive;

6. The VA content ranges from 5% to 45%, and the main products are films (including agricultural films) and sheets, injection

molded and molded products, foam products, hot melt adhesives, etc.

2. EVA with a VA content of 5% to 10%, products such as elastic film, injection molding, and foam products;

3. EVA with a VA content of 20%~28%, mainly used for hot melt adhesives and coating products;

4. EVA with a VA content of 28% -33%, photovoltaic materials, solar cell adhesives, etc;

5. EVA with a VA content of 38% -40%, adhesive;

6. The VA content ranges from 5% to 45%, and the main products are films (including agricultural films) and sheets, injection

molded and molded products, foam products, hot melt adhesives, etc.