NaN / 0

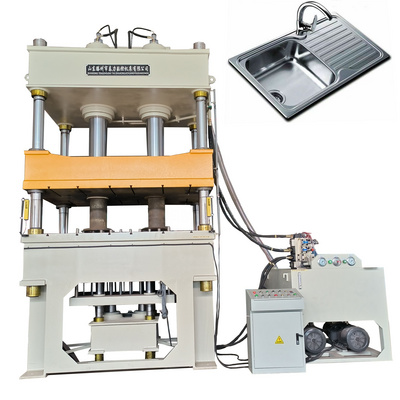

315T/400T/500T/630T/800T Four-column Hydraulic Press Forming Car Kits Press Clutch Plate Making Machine

Get Latest Price

US$ 21500

≥1 Pieces

US$ 20500

≥2 Pieces

Quick Details

Machine Type:

Four-column Three-beam Hydraulic Press

Slide Stroke (mm):

500

Ejector Force (kN):

300*2

Return Force (kN):

800 kN

Product Details

Independent electrical control system, reliable operation, intuitive action, easy maintenance. Centralized button control, with adjustment, manual and semi-automatic control.Drawing and edge pressing slider can be connected into one body to realize single action process.

The hydraulic system adopts the plug-in integrated system, which has the characteristics of sensitive action, reliable operation and good sealing performance.

The hydraulic system adopts the plug-in integrated system, which has the characteristics of sensitive action, reliable operation and good sealing performance.

|

Type Y32-800TC

|

|

|

Unit

|

Value

|

||

|

Nominal Pressure

|

|

|

KN

|

8000

|

||

|

System Pressure

|

|

|

MPa

|

25

|

||

|

Slider Stroke(customized)

|

|

|

mm

|

500

|

||

|

Maximum Opening Height(customized)

|

|

|

mm

|

900

|

||

|

Effective Size of Workbench

(customized)

|

|

The Lift and Right Sides

|

mm

|

1100

|

||

|

|

|

The Front and Rear Sides

|

mm

|

1240

|

||

|

Slider Speed

(customized)

|

|

Idle Stroke

|

mm/s

|

150

|

||

|

|

|

Feeding

|

mm/s

|

5-15

|

||

|

|

|

Back Tracking

|

mm/s

|

150

|

||

|

Plunger pump flow(customized)

|

|

|

ml/s

|

100*2

|

||

|

Return cylinder pressure(customized)

|

|

|

T

|

30T*2

|

||

|

Backing plate size(customized)

|

|

|

mm

|

900*900*130

|

||

|

Motor Power(customized)

|

|

|

KW

|

22

|

||

customer product

usage:

Used for tensile forming of sheet metal,

Diaphragm spring.

servo motor

1.Low speed operation stability is good. At lower speeds, the servo motor runs very smoothly with almost no vibration, while other motors oscillate violently, affecting accuracy.

2.High control accuracy. At present, the top servo motor has been able to achieve a pulse signal only a few hundredths of a point,and only to the control command to turn, no command will stop, will not power off because of inertia.

2.High control accuracy. At present, the top servo motor has been able to achieve a pulse signal only a few hundredths of a point,and only to the control command to turn, no command will stop, will not power off because of inertia.

3.Servo motor has a certain overload capacity, even if it exceeds the rated torque, it can work normally.

Hot Searches