NaN / 0

shutter door guide rail cold roll forming machine

Get Latest Price

US$ 9000

≥1 Sets

US$ 8700

≥2 Sets

US$ 8500

≥3 Sets

US$ 8000

≥5 Sets

Quick Details

Type:

Tile Forming Machine

Tile Type:

Colored Steel

Production Capacity:

10-15 m /min

Place of Origin:

Hebei, China

Product Details

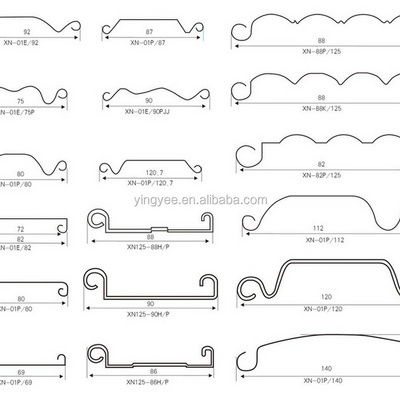

shutter door guide rail cold roll forming machine

Processing F low D iagram of M achine :

Production Process :

Uncoiling→ Feeding material into machine →Roll forming → Auto cutting →Products receiving

Technical parameters :

|

Suitable Material |

Material |

Galvanized Sheet |

|

Thickness |

1 -1.5 mm |

|

|

Material of rollers |

High grade 45# forged steel , surface hard chromium plating |

|

|

Rows of rollers |

1 2 stations |

|

|

Material of shafts |

High grade 45# forged steel |

|

|

Diameter of shaft s |

5 0mm |

|

|

Material of blade |

Cr12 Heat Treatment |

|

|

Speed |

15-20 m/min |

|

|

Side plate thickness |

16 mm |

|

|

Total power |

4 kw |

|

|

Voltage |

380 V 50HZ 3Phase |

|

|

Appearance size (About) |

45 0 0mm*8 0 0mm*15 0 0mm |

|

|

Electronic control system |

PLC + Touch Screen |

|

Standard Configuration :

|

1 ton Manual decoiler |

1 set |

|

Main roll forming machine |

1 set |

|

Hydraulic pump system |

1 set |

|

PLC control system |

1 set |

|

Receiving Table |

1 set |

|

S pare parts |

1 set |

Manual Decoiler

|

Capacity |

1 T |

|

Inner Diameter |

450-550mm |

|

Width |

300 mm |

Spare Parts

Receiving Table

Packing Method

Main machine is packaged with plastic film

Transportation

All machines need one 2 0 feet container to hold

Payment Term

30% deposit by T/T in advance and 70% balance after inspection confirmation before shipment .

Delivery Time

Within 3 5 days after receiving deposit .

Warranty

Two year s , and we will provide technical support for wholelife of the equipment.

If some parts of machine broken within 2 year, we will give customer the spare parts for free. (include chain, bearing, roller,oil pipe, counting wheel) If more than 2 year, maybe some spare parts need to be charged. If machine can not work well, we can teach them online until the machine is perfect. If you need, we can go to your place to assist you . But y ou need to provide the cost of the engineer .

Hot Searches