NaN / 0

Automatic Nut And Bolt Making Former Machine Nut Hot forging Screw Cold Heading Manufacturing

Get Latest Price

US$ 18750

≥1 Sets

US$ 18200

≥3 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

Huarui

Weight (KG):

4000

Marketing Type:

Hot Product 2023

Product Details

Product Overview

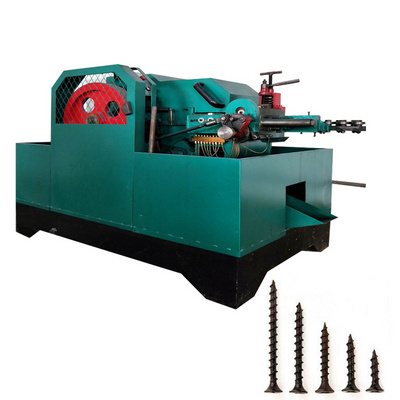

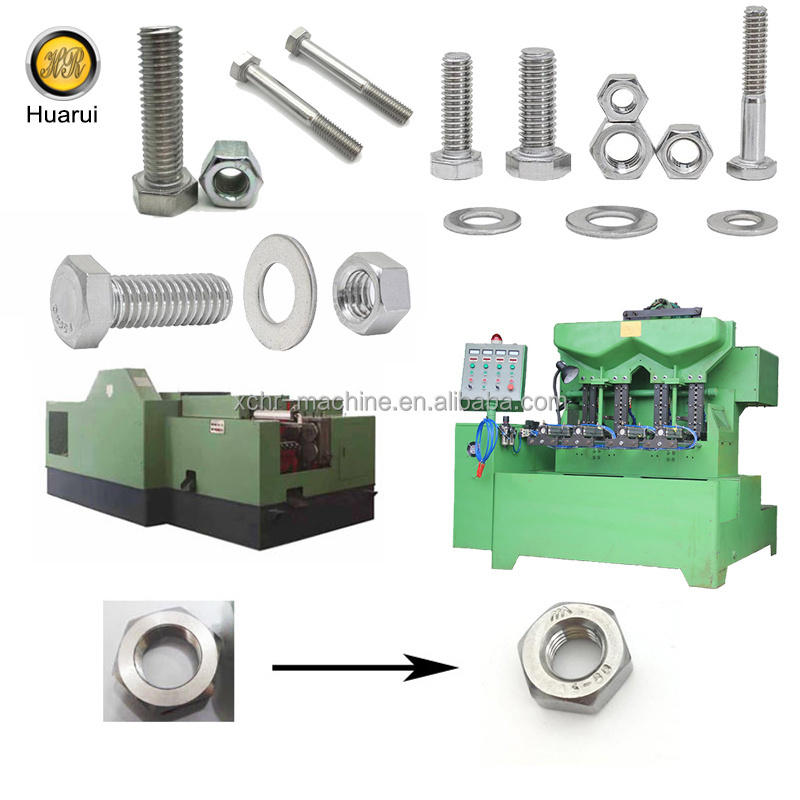

Nuts Bolts Making Machine Automatic Nut Forging Machine

Automatic high speed 6 station bolt nut making machine nut former with computer control

Step 1. Multi-Station nut forging machine

This machine adopts the cold heading method to automatically discard various hex nuts after the tapping of the disc element or the bar material, that is, the standard hex nut.

The bar material is fed through the roller drive, feeding, cutting, pressing, pressing, punching, and several processes are completed. The cold heading station is arranged horizontally, with accurate positioning, stable operation and convenient maintenance. It is suitable for manufacturers to mass produce nuts.

The bar material is fed through the roller drive, feeding, cutting, pressing, pressing, punching, and several processes are completed. The cold heading station is arranged horizontally, with accurate positioning, stable operation and convenient maintenance. It is suitable for manufacturers to mass produce nuts.

|

Model

|

11B6S

|

14B6S

|

17B6S

|

19B6S

|

24B6S

|

33B6S

|

|

Dies

|

6

|

6

|

6

|

6

|

6

|

6

|

|

Forging Power (ton)

|

60

|

95

|

120

|

150

|

250

|

400

|

|

Cut-off Dia.(max) mm

|

11

|

16

|

18

|

20

|

24

|

32mm

|

|

Cut-off Length (mm)

|

7

|

11

|

13

|

20

|

30

|

30mm

|

|

Making Size (DIN)

|

M6

|

M8

|

M10

|

M12

|

M16

|

M16-M22

|

|

Output (Pcs/Min)

|

260

|

180

|

160

|

130

|

110

|

100pcs/min

|

|

Slide Ram (mm)

|

50

|

70

|

80

|

100

|

110

|

160mm

|

|

Kick-out Length(max) (mm)

|

11

|

18

|

20

|

30

|

35

|

40mm

|

|

Dies Pitch (mm)

|

50

|

60

|

70

|

80

|

100

|

140mm

|

|

Main Motor (kw)

|

11

|

15

|

22

|

37

|

45Kw

|

75kw

|

|

Lubricant Motor (kw)

|

1.5

|

1.5

|

3

|

3

|

3

|

3kw

|

|

Lubricant oil (Litre)

|

540

|

720

|

900

|

1080

|

1440

|

1800L

|

|

Weight (Ton)

|

4

|

8

|

10

|

15

|

25

|

48ton

|

|

Dimention (m)

|

2.15*1.55*1.06

|

2.8*2.05*1.3

|

3.67*2.05*1.4

|

4.0*2.45*1.45

|

5.0*3.0*1.7

|

6.0*3.2*1.8M

|

Step 2. Nut Tapping Machine

This machine is a standard machine for producing M3-M12 and M12-M30 nut tapping. As long as the nut blank is put into the hopper, it can be directed into the track to complete the automatic nut tapping. Can be used for ordinary hex nuts, flange nuts, coarse and fine tapping. The nut has a high finish and a pass rate of 100%. The mechanical action is automatic continuous tapping, and one person can operate several units.

|

Model

|

HR-M8B-D4G

|

HR-M12B-D4G

|

HR-M14B-D4G

|

HR-M16B-D4G

|

HR-M18B-D4G

|

HR-M20B-D4G

|

|

Tapping Range

|

M6-8

|

M10-12

|

M14

|

M16

|

M18

|

M20

|

|

Capacity (pcs/min)

|

180-240

|

112-148

|

76-84

|

68-76

|

48-56

|

40-48

|

|

No. of spindle

|

4

|

4

|

4

|

4

|

4

|

4

|

|

Motor Powder (Kw)

|

4.7

|

6.3

|

6.3

|

10.2

|

10.2

|

10.2

|

|

Weight (Ton)

|

1

|

1.2

|

1.2

|

1.8

|

1.8

|

2.2

|

|

Dimension

|

1.2*1.2*1.6

|

1.6*1.6*1.6

|

1.6*1.6*1.6

|

1.6*1.6*1.6

|

1.8*1.8*1.9

|

1.8*1.8*1.9

|

Finished Nuts:

Related Machines

Product packaging

Customer Photos

FAQ

1. Make response to customer's inquiry or requirement within 24 hours.

2. Assist customer to select the most suitable machine and give them our professional suggestion.

3. Produce machine by our experienced team according to customer requirement.

4. Provide customer operation manual or video for machine to help them operate machine more efficiently.

5. Provide customer layout of workshop with machine to help them install machine.

6. Assign engineer to assist customer to install machine.

7. Offer 2 year guarantee for our machines.

2. Assist customer to select the most suitable machine and give them our professional suggestion.

3. Produce machine by our experienced team according to customer requirement.

4. Provide customer operation manual or video for machine to help them operate machine more efficiently.

5. Provide customer layout of workshop with machine to help them install machine.

6. Assign engineer to assist customer to install machine.

7. Offer 2 year guarantee for our machines.

Hot Searches