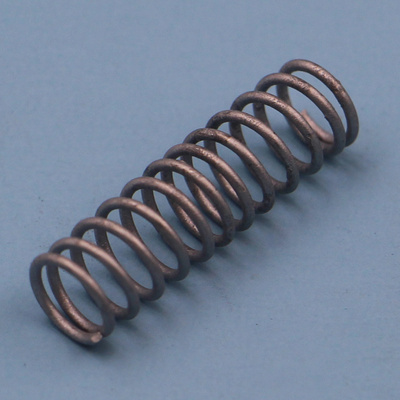

Major original equipment manufacturers (OEMs) that produce products for various industries use compression springs in many of their products. Because of this, companies like us have the ability to produce large orders for our clients. If you need a large order, don’t hesitate to ask us for a quote.

Some of the many industries that we serve include:

* Manufacturing

* Transportation

* Construction

* Materials handling

* Agriculture

* Petrochemical

* Aeronautical

* And, many others