NaN / 0

Semi Automatic 5 Gallon PET plastic Bottle Blowing making Machine price

Get Latest Price

US$ 3000

≥1 Sets

Quick Details

Neck Diameter(mm):

80 mm

Max.Bottle Diameter(mm):

350 mm

Max.Bottle Height(mm):

600 mm

Bottle Volume(ml):

20000 ml

Product Details

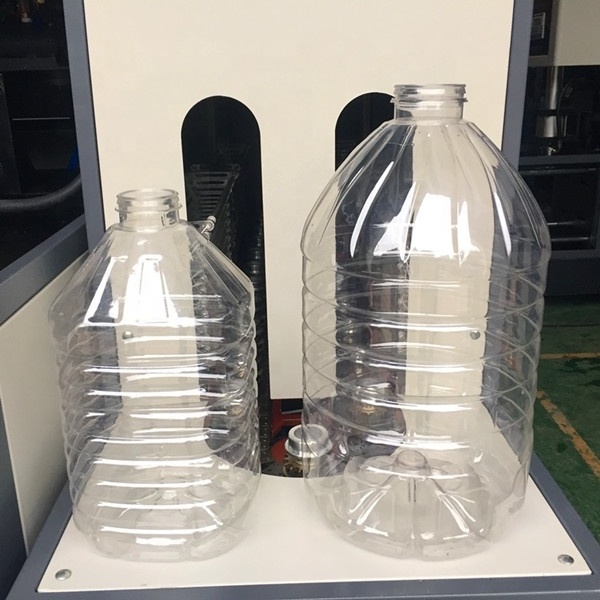

Details Images

Semi-automatic Bottle blow moulding machine for 5gallon water bottle:

Product Description

|

Semi-automatic blow moulding machine Main part:

|

|

|

||

|

Pneumatic part

|

Valve

|

SMC/PARK/FESTO/AIRTAC etc

|

||

|

|

Cylinder

|

|

||

|

Electric part

|

PLC

|

Mitsubishi/Siemens/Delta etc

|

||

|

|

Operating system

|

Mitsubishi/Siemens/Delta etc

|

||

|

|

Contactor

|

Schneider

|

||

|

|

Relay

|

OMRON

|

||

|

|

Infrared thermometer

|

America raytek

|

||

|

Note

|

All of the electrical components adopts CE\UL\CCC approved

international advanced high-tech product. |

|

||

Semi-automatic blow moulding machine performance:

1.Stable performance with advanced PLC.

2.Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the

rails simultaneously in the infrared preheater.

3.High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the

reflecting board in the preheating area and eternal temperature in the preheater with an automatic thermostatic apparatus.

4.High safeties with security automatic-locking apparatus in each mechanical action,which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

5.No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

6.Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

7.Strong clamping force with high pressure and double crank links to lock the mold.

8.Operating: Manual.

9.Safe,reliable and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

10.Low cost,high efficiency,easy operation,easy maintenance,etc.

11.Contamination is avoided for the bottle body.

12.Ideal effect of the chilling with the chilling system for the bottle mould.

13.Easy installation and starting.

14.Low rejection rate:less than 0.2 percent.

15.Manual saving, one man is enough for operation the machine.

16.Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

17.Power saving design that can increase your profits.

18.Separated type air controlling system, which is designed for avoiding waste pollution.

2.Strong penetrability and good and swift distribution of the heat by letting the bottles rotate by itself and revolute in the

rails simultaneously in the infrared preheater.

3.High adjustability to enable the preheater to preheat preforms in shapes by adjusting the light tube and the length of the

reflecting board in the preheating area and eternal temperature in the preheater with an automatic thermostatic apparatus.

4.High safeties with security automatic-locking apparatus in each mechanical action,which will make the procedures turn into a state of safety in case of a breakdown in certain procedure.

5.No contamination and low noise with the air cylinder to drive the action instead of the oil pump.

6.Satisfaction with different atmospheric pressure for blowing and mechanical action by dividing the blowing and action into three parts in the air pressure diagram of the machine.

7.Strong clamping force with high pressure and double crank links to lock the mold.

8.Operating: Manual.

9.Safe,reliable and unique design of the position of valve to make the air pressure diagram of the machine easier to understand.

10.Low cost,high efficiency,easy operation,easy maintenance,etc.

11.Contamination is avoided for the bottle body.

12.Ideal effect of the chilling with the chilling system for the bottle mould.

13.Easy installation and starting.

14.Low rejection rate:less than 0.2 percent.

15.Manual saving, one man is enough for operation the machine.

16.Adopt the new type double bend arm and the four rod-clamping structure(won the patent): Cross direction; Middle mould board is move parallel; the distance between two mold board is adjusted by the chain wheel. Thus, the clamping force is very strong.

17.Power saving design that can increase your profits.

18.Separated type air controlling system, which is designed for avoiding waste pollution.

If you have any requirement for

Semi-automatic blow moulding machine

, welcome to contact me!!!

Main products

Packing & Delivery

Plastic bottle blow molding machine

Package::Anti-rust oil is smeared first, then plastic waterproof film, and finally standard plywood case/ fumigated wooden

boxoutside for export.

Spare parts together with the machine shipment

Package::Anti-rust oil is smeared first, then plastic waterproof film, and finally standard plywood case/ fumigated wooden

boxoutside for export.

Spare parts together with the machine shipment

Hot Searches