QUALITY

Gives you the ability to cut parts faster and more accurately than with a standard non-Dynamic waterjet.

VARIABILITY

1. Name : Small size Waterjet Cutter Water Jet propulsion CNC Machine for metal Stone Marble Cutting 3 4 5 Axis Water jet Cutting Machine

2. Pressure : 60000psi

3. Application: Water jet cutting machine

4. Certification: ISO9001, SGS, CTI, ROHS

|

Product Name

|

Small size Waterjet Cutter Water Jet propulsion CNC Machine for metal Stone Marble Cutting 3 4 5 Axis Water jet Cutting Machine

|

|

Power Consumption

|

37KW/50HP

|

|

Flow

|

3.7L/min

|

|

Pressure

|

413mpa

|

|

Power

|

220/380/415VAC 50/60HZ

|

|

Continous Working Pressure

|

360Mpa

|

|

Application

|

Water jet cutting machine

|

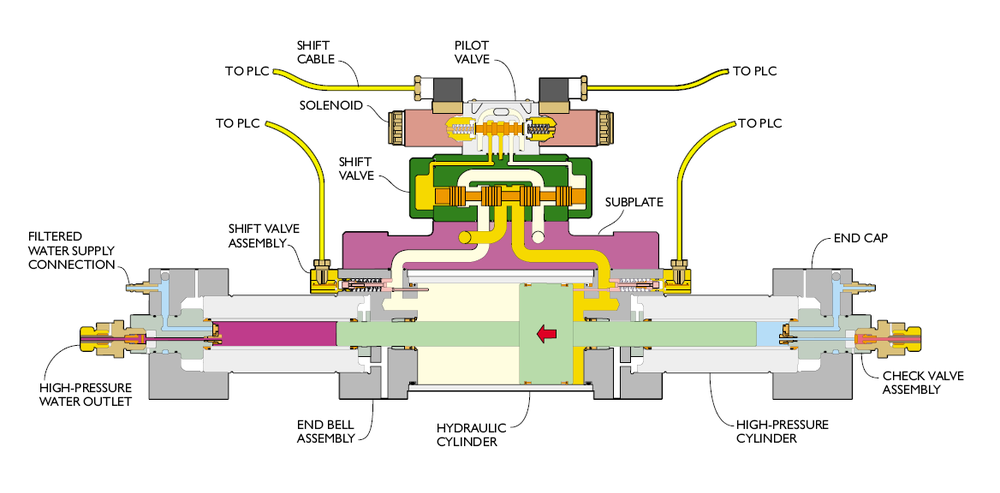

What's Intensifier Pump for Water Jet Cutting Machine ?

The linear intensifier pump is the original, and most common, technology used in waterjet cutting. Intensifier pumps use the “intensification principle” to pressurize water.

The “intensification principle”, or ratio, uses the difference in biscuit/plunger area to intensify, or increase the pressure. Hydraulic oil is pressurized and the low pressure oil pushes against a biscuit, which has a face area 20 times greater than the face of the high pressure plunger that pushes against the water. Therefore, the pressure is “intensified” twenty times. E.g., 3,000 psi of oil pressure will generate 60,000 psi of water pressure due to the 20:1 ratio of biscuit area to plunger area.

Our Workshop

Our Warehouse

Our Team

Company Events

**2012,

Fedjetting set up the ultra-high pressure water washing machine assembly plant in the cooperation with JETSTREAM (USA), and put enough ultra-high pressure pump and spare parts in stock to achieve domestic supply of JETSTREAM ultra-high pressure water washing machine;

**2012,

Fedjetting becomes Stoneage's largest agent in China and the designated maintenance center in Asia-Pacific region.

**2014,

Cooperated with the TST(Swedish company), and becomes TST's tier-one Agentas in China.

**2015,

Introducing the R&D, production, sales and technical services of Water jet cutting parts and began to serve domestic market.

**2016,

Introducing the R&D, production, sales and technical services of ultra high pressure cutting system and started to cooperate with different big water jet cutting company.

**2016,

Customized assembly business of ultra-high pressure cleaning machine was launched. Fedjetting is built into the most professional assembly company according to different market demands.

**2017,

Trend50pro intensifier pump was launched to market.

**2017,

Cooperated with Dongna university to develop the remote monitor system for UHP Intensifier pump

**2018,

The new arrival reactor full automated cleaning system was launched for fine Chemistry

**2018,

5axis laser testing system was put in to use.

**2019,

The zebra stripes washer with full automated recycling function was launched

**2019,

FedJet Cangzhong production base phase II started to build

QUALITY

APPLICATION

Our

waterjet's cutting ability to generate exact, clean cuts with speed make it an efficient cutting process for different applications.

|

APPLICATION FIELD OF WATER JET CUTTING

|

|

|

|

|||

|

1, Ceramic and stone

|

2, Glass spell flower

|

3, High speed way

|

4, Automobile spare parts

|

|||

|

5, Airplane manufacturer

|

6, Aviation aerospace

|

7, Nuclear power

|

8, Army industry

|

|||

|

9, Foundry industry

|

10, Cleaning scope

|

11, Jewelry industry

|

12, Paper industry

|

|||

|

13, Children diaper industry

|

14, Women sanitary towel

|

15, Food industry

|

16, Electron industry

|

|||

A: We are factory.

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below: