NaN / 0

Replace complex calcium extreme pressure lithium base grease extended grease cycle SINOPEC 7019 high temperature grease

Get Latest Price

US$ 97.28

≥1 Pieces

Quick Details

Application:

Industrial Lubricant

Type:

Greases

Place of Origin:

Beijing, China

Brand Name:

SINOPEC

Product Details

Typical Data

|

Items

|

Quality Index

|

|

Appearance

|

Yellow smooth uniform ointment

|

|

Working cone penetration(1/4 Working cone penetration,0.1mm)

|

62~75

|

|

Dropping Point,℃ ≥

|

260

|

|

Evaporativity(180),%(m/m) ≤

|

5.0

|

|

Consistency Number(NLGI)

|

2

|

|

Base oil Viscosity

40℃ mm

2

/s

100℃ mm2/s |

300

18~22

|

|

Similar Viscosity(-20℃,10s),Pa·s ≤

|

1500

|

|

Pressure oil separation,%(m/m) ≤

|

16

|

|

Carrying Capacity

|

1373

|

|

Chemical stability,pressure drop,MPa ≤

|

0.034

|

FAQ

Q1.What are the production method of the product?

A:

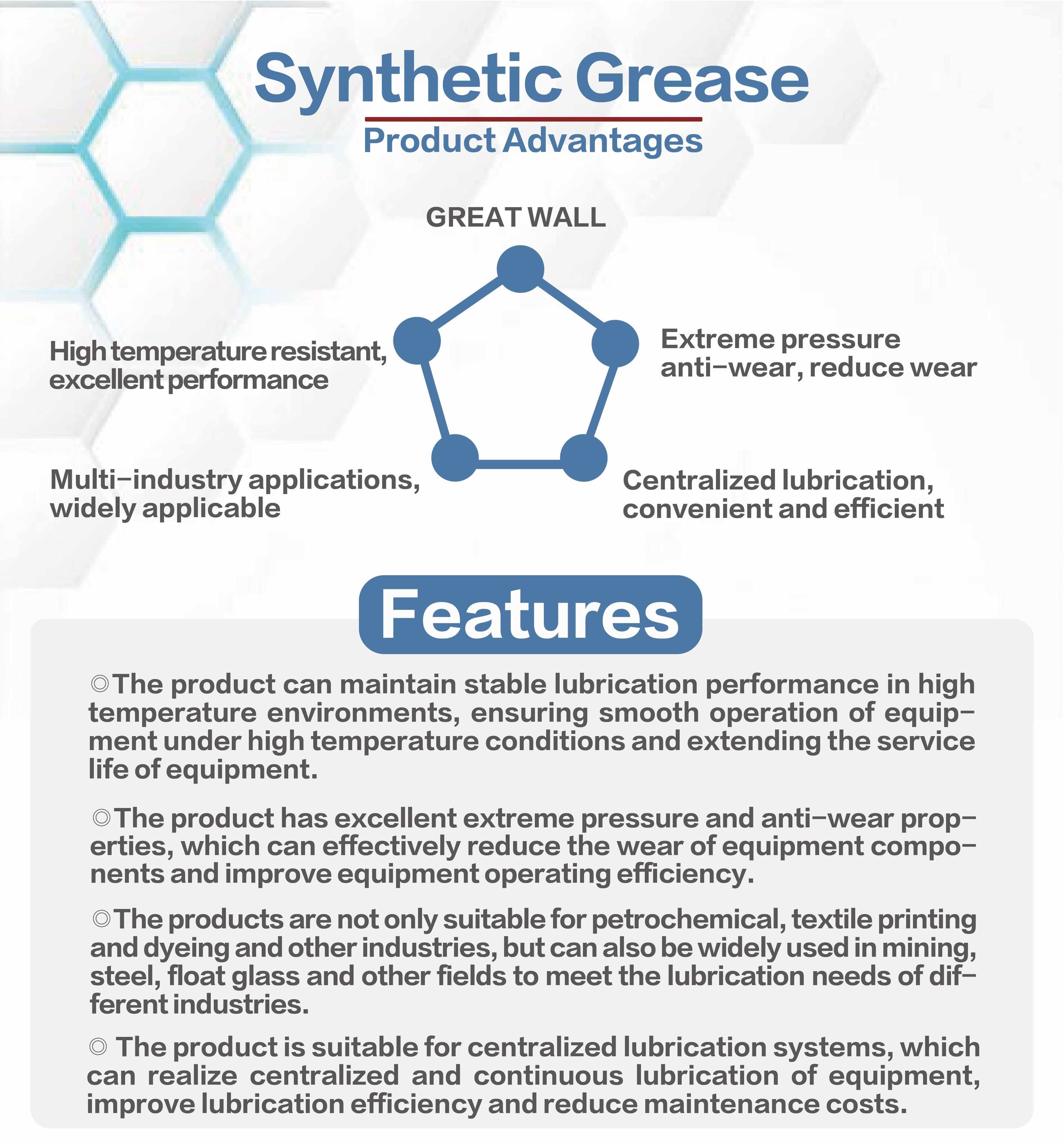

This product is made by thickening semi-synthetic oil with composite soap and adding additives such as extreme pressure, antioxidant and rust prevention.

Q2.What are the performance feature of the product?

A:First, this product has extreme pressure anti-wear and good anti-rust properties to provide effective lubrication for the bearing parts, reduce wear and prevent corrosion of metal parts; Second,this product has excellent oxidation stability, prevent grease deterioration at high temperature, and ensure a long service life at high temperature. And,this product has good anti-fretting wear performance to prevent pitting corrosion and wear under fretting conditions.

Q3.What are the main uses of the products ?

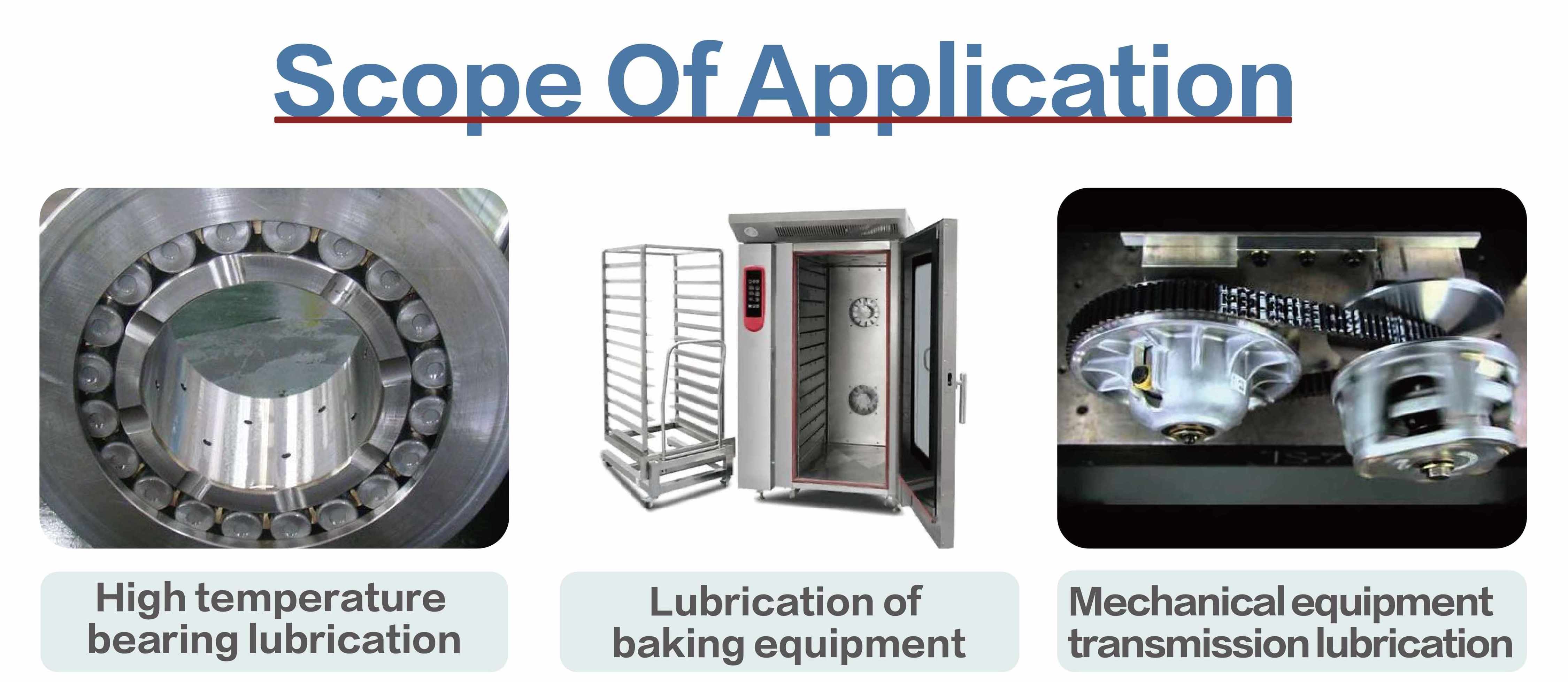

A: This product is suitable for petrochemical, textile, printing and dyeing, mining, steel and float glass and other industries in the production of high temperature bearings, all kinds of medium and heavy load ball, roller, plain bearing and baking equipment gear, chain wheel and other transmission parts and shaft joint lubrication.

Q4.What is the storage method of the product?

A:This product should be sealed storage.

Q5.How long is the shelf life of the product?

A:It can be stored for 1 year after opening, and for f5 years if it is not opened.

Q6.Whether the product complies with relevant standards?

A:Yes, this product complies with relevant national and international standards,sunch as Q/SH303 151-2004.

Q7.Does the product support samples?

A:This product is measured in barrels, the MOQ is 1 barrel. Therefore, free samples are currently not available. If a small quantity is required, 1 barrel can be ordered .

Q8.How long is the delivery time?

A:The delivery time is generally 5-10 days, and for urgent orders, you can also contact customer service for expedited processing. And the time of delivery to your country depends on the region and logistics method.

Q9.What should I do if I encounter problems during use?

A:If you encounter any problems during use, please feel free to contact the store customer and we will respond to your message as soon as possible.

Q10.Product precautions!

A:Prevent packaging damage during storage and transportation, and prevent water and impurities from being mixed during use.

Q2.What are the performance feature of the product?

A:First, this product has extreme pressure anti-wear and good anti-rust properties to provide effective lubrication for the bearing parts, reduce wear and prevent corrosion of metal parts; Second,this product has excellent oxidation stability, prevent grease deterioration at high temperature, and ensure a long service life at high temperature. And,this product has good anti-fretting wear performance to prevent pitting corrosion and wear under fretting conditions.

Q3.What are the main uses of the products ?

A: This product is suitable for petrochemical, textile, printing and dyeing, mining, steel and float glass and other industries in the production of high temperature bearings, all kinds of medium and heavy load ball, roller, plain bearing and baking equipment gear, chain wheel and other transmission parts and shaft joint lubrication.

Q4.What is the storage method of the product?

A:This product should be sealed storage.

Q5.How long is the shelf life of the product?

A:It can be stored for 1 year after opening, and for f5 years if it is not opened.

Q6.Whether the product complies with relevant standards?

A:Yes, this product complies with relevant national and international standards,sunch as Q/SH303 151-2004.

Q7.Does the product support samples?

A:This product is measured in barrels, the MOQ is 1 barrel. Therefore, free samples are currently not available. If a small quantity is required, 1 barrel can be ordered .

Q8.How long is the delivery time?

A:The delivery time is generally 5-10 days, and for urgent orders, you can also contact customer service for expedited processing. And the time of delivery to your country depends on the region and logistics method.

Q9.What should I do if I encounter problems during use?

A:If you encounter any problems during use, please feel free to contact the store customer and we will respond to your message as soon as possible.

Q10.Product precautions!

A:Prevent packaging damage during storage and transportation, and prevent water and impurities from being mixed during use.

Avoid skin contact with grease when using.

After use, smooth the surface of the grease, seal the package, and do not mix with other greases.

Grease can not be used by heating, and should be extinguished immediately with dry powder or foam fire extinguisher in case of fire.

Hot Searches