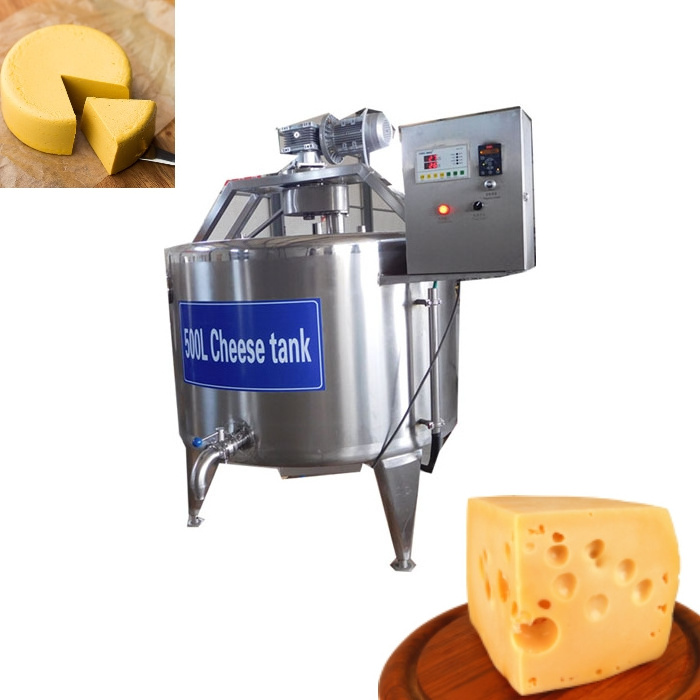

Structural composition of cheese machine:

Tank body, three cutters, electric empty cabinet, outrigger, whey outlet, etc.

By manually controlling the temperature and stirring, the functions of mixing milk ingredients, milk fermentation, coagulation of

milk with rennet, whey cutting, heating and cooling can be realized.

It is suitable for curd processing of most cheeses. Can body is

Three layer stainless steel structure with heating, inner and middle tank water jacket middle and outer tank insulation layer.

Pasteurization and cooling of milk can be realized, and milk can be quickly cooled by cooling water through jacket.

At the same time, it is equipped with a temperature control box, which can accurately control the temperature. Under certain

temperature conditions, milk is fermented in vats, and rennet is added to coagulate milk.

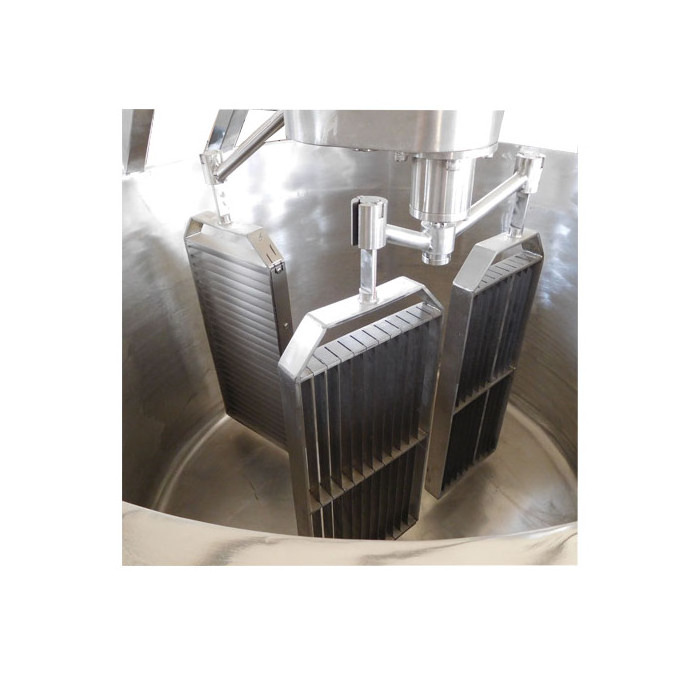

The machine is equipped with a curd cutter, which cuts the curd into small pieces of uniform size so that whey can be easily

discharged.

The equipment is equipped with a large-diameter discharge port, which is located at the lowest point of the tank to facilitate the

emptying of whey. After discharging the whey, empty and clean the whey in the curd tank to produce cheese again.

Tank body, three cutters, electric empty cabinet, outrigger, whey outlet, etc.

By manually controlling the temperature and stirring, the functions of mixing milk ingredients, milk fermentation, coagulation of

milk with rennet, whey cutting, heating and cooling can be realized.

It is suitable for curd processing of most cheeses. Can body is

Three layer stainless steel structure with heating, inner and middle tank water jacket middle and outer tank insulation layer.

Pasteurization and cooling of milk can be realized, and milk can be quickly cooled by cooling water through jacket.

At the same time, it is equipped with a temperature control box, which can accurately control the temperature. Under certain

temperature conditions, milk is fermented in vats, and rennet is added to coagulate milk.

The machine is equipped with a curd cutter, which cuts the curd into small pieces of uniform size so that whey can be easily

discharged.

The equipment is equipped with a large-diameter discharge port, which is located at the lowest point of the tank to facilitate the

emptying of whey. After discharging the whey, empty and clean the whey in the curd tank to produce cheese again.