NaN / 0

Boiler parts stainless steel elliptical dished end tank head

Get Latest Price

US$ 40

≥10 Pieces

US$ 25

≥50 Pieces

US$ 10

≥100 Pieces

Quick Details

Technics:

Forged

Shape:

dished

Head Code:

circular

Place of Origin:

Hebei, China

Product Details

Products Description

|

Item

|

Torispherical / Ellipsoidal Dished Heads

|

|

Diameter

|

89-10000 mm

|

|

Thickness

|

2-300 mm

|

|

Reduction Ratio

|

About 10%

|

|

Material

|

Carbon steel (Q235,Q245,Q235R,Q245R,Q345B)

stainless steel (304,321,304L,316,316L), etc

According to customers’ requirement.

|

|

Technology

|

Hot pressing/cold pressing

|

|

Surface Treatment

|

Sandblasting/pickling/polishing

|

|

Test

|

UT,RT,MT,PT,ET

|

|

Applicable Standard

|

ANSI, ASME ,MSS, API, DIN, JIS, BS. AWWA and GB

|

|

Certificate

|

ISO9001 ,ISO14001,OHSAS18001

|

|

Applications

|

Mainly used in petroleum, electronics, chemical industry, medicine, textile, food, machinery, construction, nuclear power,

aerospace, military and other industries. |

|

Connection

|

Butt-welding

|

The punching head is a component of the container.

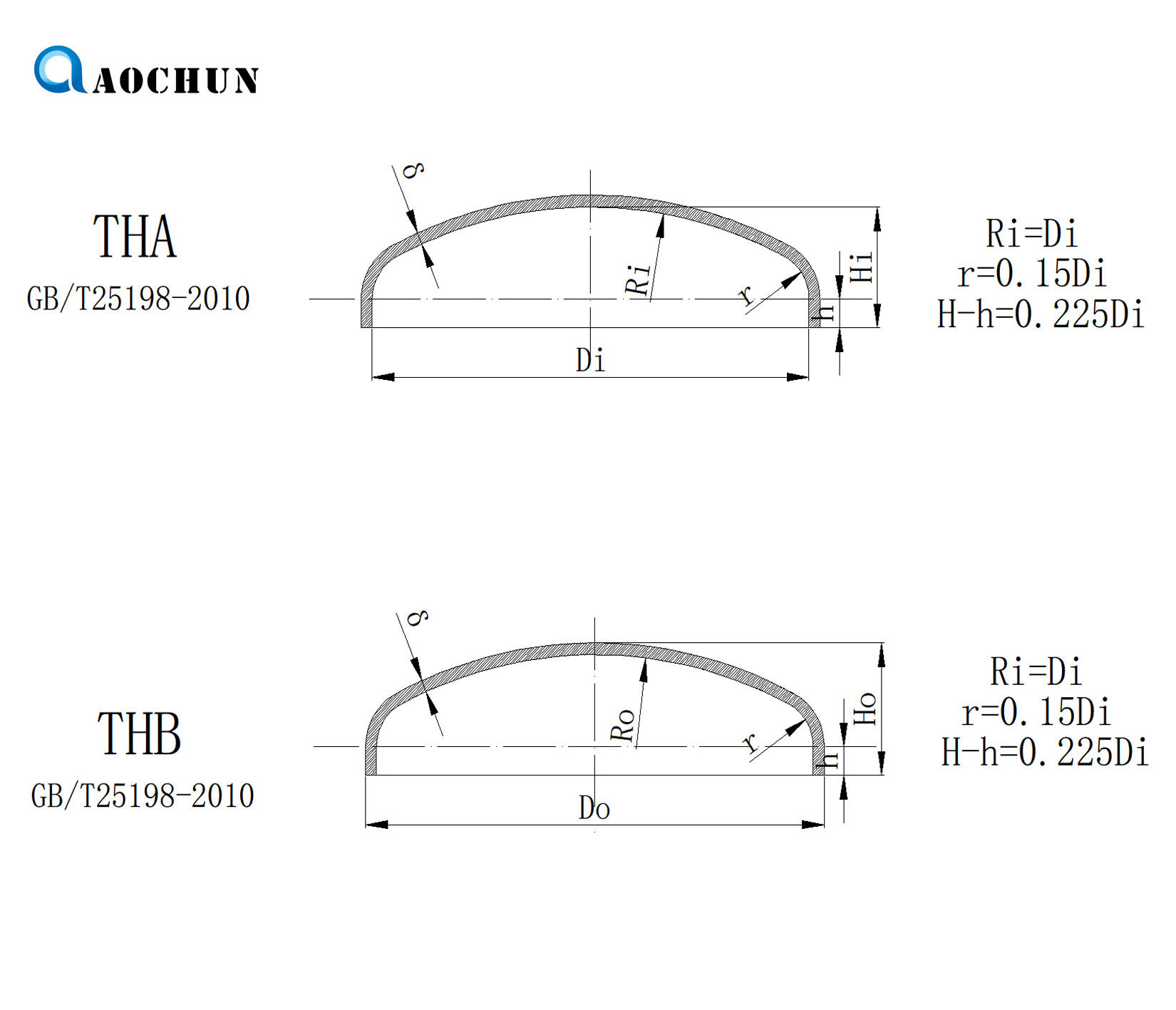

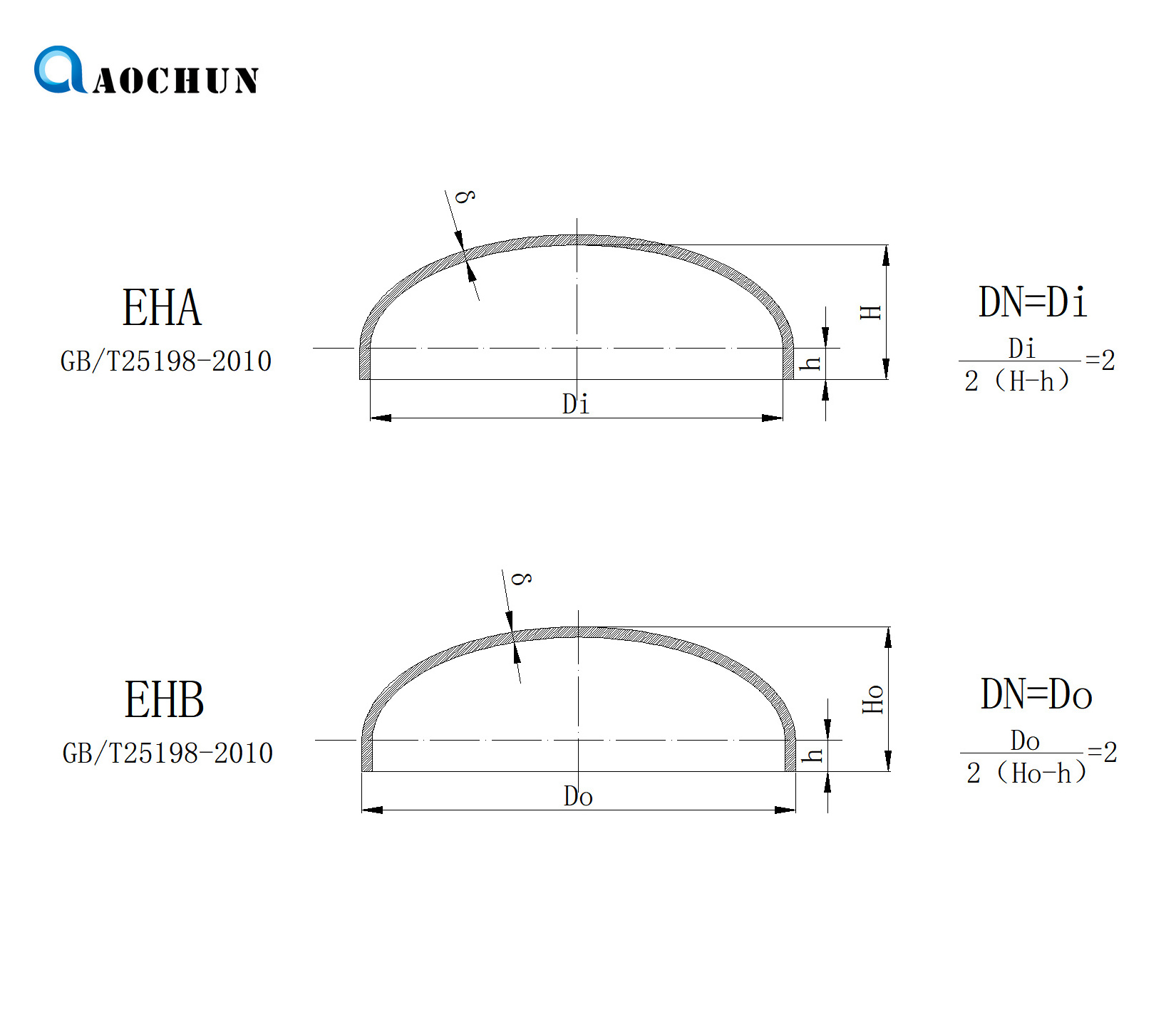

According to different geometric shapes, it can be divided into spherical, elliptical, dish, spherical crown, cone shell and flat

bottom, among which spherical, elliptical, dish, and spherical crowns are collectively referred to as convex heads.

The punching head is used in a variety of container equipment, such as storage tanks, heat exchanger, towers, reactors, boilers

and separation equipment.

Punching heads are generally made according to drawings and OEM is available.

Punching heads are made by stamping just like other heads.

Material: carbon steel and stainless steel.

bottom, among which spherical, elliptical, dish, and spherical crowns are collectively referred to as convex heads.

The punching head is used in a variety of container equipment, such as storage tanks, heat exchanger, towers, reactors, boilers

and separation equipment.

Punching heads are generally made according to drawings and OEM is available.

Punching heads are made by stamping just like other heads.

Material: carbon steel and stainless steel.

Production process

Product packaging

Company information

Xinji Aochun Head Manufacturing Co., Ltd was established in 1998. Which is a factory specializing in the manufacture of boilers

and pressure vessels heads. The factory is located in Xinleitou industrial zone,Xinji City, Hebei Province beside the 307 National

Road.Covering an area of 50 acres, the existing assets is 150 million.

The company mainly produces and processes various elliptical heads, spherical heads, dished heads, flat bottom heads, spherical

crown heads, conical heads and boiler punched heads with 500T,1200T,2000T three hot pressing production lines and 1200T,2000T,

6000T cool pressing production lines. At the same time, it has 9000mm×50mm,4600mm×26mm,2500mm×18mm cold spinning overall forming

equipment and Plasma welding machine and CNC cutting equipment.

In 2006, the company obtained the A3 head manufacturing license issued by the state.In the past 20 years, Xinji Aochun Head

Manufacturing Co., Ltd has established a long-term cooperative relationship with more than 100 pressure vessel and boiler

manufacturers with its solid funds, sound quality assurance system and stable product performance.

We believe that "survive by quality, benefit by management, and develop by innovation" is the cornerstone of the company's

continuous success. All staff of Xinji Aochun Head Manufacturing Co., Ltd warmly welcome new and old friends at home and abroad to

visit and inspect, and work together to create a better future.

and pressure vessels heads. The factory is located in Xinleitou industrial zone,Xinji City, Hebei Province beside the 307 National

Road.Covering an area of 50 acres, the existing assets is 150 million.

The company mainly produces and processes various elliptical heads, spherical heads, dished heads, flat bottom heads, spherical

crown heads, conical heads and boiler punched heads with 500T,1200T,2000T three hot pressing production lines and 1200T,2000T,

6000T cool pressing production lines. At the same time, it has 9000mm×50mm,4600mm×26mm,2500mm×18mm cold spinning overall forming

equipment and Plasma welding machine and CNC cutting equipment.

In 2006, the company obtained the A3 head manufacturing license issued by the state.In the past 20 years, Xinji Aochun Head

Manufacturing Co., Ltd has established a long-term cooperative relationship with more than 100 pressure vessel and boiler

manufacturers with its solid funds, sound quality assurance system and stable product performance.

We believe that "survive by quality, benefit by management, and develop by innovation" is the cornerstone of the company's

continuous success. All staff of Xinji Aochun Head Manufacturing Co., Ltd warmly welcome new and old friends at home and abroad to

visit and inspect, and work together to create a better future.

Our Service

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. After sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

FAQ

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 15to 25 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

A: Generally, we pack our goods in neutral white boxes and brown cartons. If you have legally registered patent,

we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 15to 25 days after receiving your advance payment. The specific delivery time depends

on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and

the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q8: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Other Products

Contact us

Hot Searches