NaN / 0

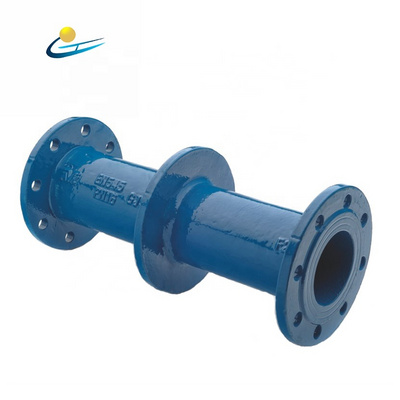

JSP PN10/16/25 ISO2531 DI Flanged Pipe Fittings Ductile Iron Double Flange Pipe With Puddle Flange Made In China

Get Latest Price

US$ 1200

≥1 Tons

Quick Details

Technics:

Clay sand casting, Coated sand casting, lost foam casting

Shape:

Equal

Head Code:

Round

Place of Origin:

China

Product Details

|

Products Name:

|

Ductile iron pipe fittings

|

|

||

|

Manufacturing Standard:

|

ISO 2531 EN545/598 AWWA C110/C153

|

|

||

|

Material:

|

Ductile iron 500-7/450-12 as per ISO 1083

|

|

||

|

Class:

|

K12, K14 for Tee and Cross

|

|

||

|

Wall Thickness Calculation:

|

e=K(0.5+0.001DN)

|

|

||

|

Type of joint:

|

Flanged/Push-in(Tyton)/Mechanical(K)/Restrained/PVC

|

|

||

|

Flange drilling:

|

ISO 7005-2/EN1092-2

|

|

||

|

|

|

|

||

|

Chemical analysis:

|

C: 3.4-3.9%

Si: 2.5-3.0%

Mn: ≤0.4% S: ≤0.02% P: ≤0.08% Mg: 0.02-0.06% RE: 0.02-0.04% |

|

||

|

|

|

|

||

|

Mechanical Properties:

|

Tensile strength:

|

≥420 N/mm²

|

||

|

|

Yield strength:

|

≥300 N/mm²

|

||

|

|

Elongation:

|

≥5 %

|

||

|

|

Brinell hardness:

|

≤250 HB

|

||

|

|

|

|

||

|

Linning:

|

Standard:

|

ISO 4179

|

||

|

|

Material:

|

Cement mortar lining(G.P./S.R./H.A.)

Fusion bonded epoxy

Painting Epoxy PU |

||

|

|

|

|

||

|

Coating:

|

Standard:

|

ISO 8179

|

||

|

|

Material:

|

Zinc&Bitumen

Fusion bonded epoxy

Painting Epoxy PU |

||

|

|

|

|

||

|

Marking:

|

Casted on body:

|

Logo

Standard

DI Size Class&Pressure Month & year of manufacture |

||

|

|

|

|

||

|

Inspection Standard:

|

ISO 2531 EN545/598 AWWA C110/C153

|

|

||

JSP products strictly meet the standards as follow:

ISO2531 Ductile iron pipes, fittings and accessories for pressure pipelines.

BSEN545 Ductile iron pipes, fittings and accessories and their joints for water pipelines. Requirements and test methods.

BSEN598 Ductile iron pipes, fittings, accessories and their joints for sewage application-requirements and test methods.

ISO4179 Ductile iron pipes for pressure and non pressure pipelines-Centrifugal cement mortar lining-general requirements.

ISO8179 Ductile iron pipes-External zinc coating.

ISO4633 Rubber Seals – joint rings for water supply, drainage and sewerage pipelines-specs for materials.

Gaskets&F

astener

can be supplied in according to customers' requirement.

D.I. fittings with

customized dimension

are available.

Hot Searches