NaN / 0

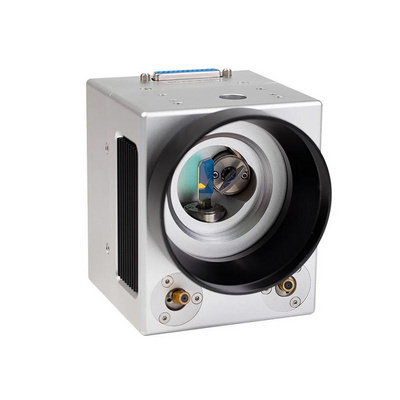

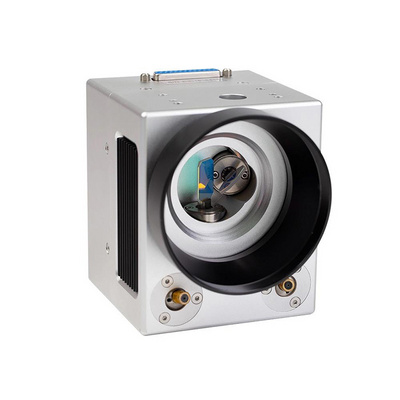

HUNST 1064nm Fiber Laser Scanning Galvo Head RC7110 SG7110 With Red Pointer 0-100W Input Aperture 10mm for Metal Marking Machine

Get Latest Price

US$ 290

≥1 Pieces

Quick Details

Place of Origin:

Guangdong, China

Spare Parts Type:

Laser machine parts, laser galvo scanner

Marketing Type:

New Product 2021

Brand Name:

SINO-GALVO

Product Details

HUNST 1064nm Fiber Laser Scanning Galvo Head RC7110 SG7110 With Red Pointer 0-100W Input Aperture 10mm for Metal Marking Machine |

Description

Introduction:

SG7110 galvanometer is mainly suitable for high-speed and online flying marking. The standard incident spot diameter is 10mm. The galvanometer system has the characteristics of zero drift, fast speed, small size, low temperature and stable and reliable operation. The comprehensive performance indicators have reached the international professional level and have obtained a number of national patents.

Features:

1. Adopted the photoelectric sensors which imported from America, and owned the proprietary intellectual property rights.

2. Differential photoelectric sensor for accurate detection of motor rotor position, good linearity, lower drift, high resolution and repeat positioning.

3. Accurate load design for 10 mm mirrors, high accuracy of motor assembly, reasonable structure, very small static friction coefficient and zero offset, all ensured the best dynamic characteristics for the whole system.

4. Drives with advanced detection ability of position and speed, greatly improved the dynamic response performance and scanning speed of the whole system.

5. Design of overload, over-current and reverse connect protection, makes the system running more reliable.

6. The whole system adopted the optimization Designing of electromagnetic compatibility, with high signal-to-noise ratio and strong anti-interference ability.

7. This scanner system solved the common problems of motor temperature drift, signal interference and zero drift, etc.

Our Service

1. Pre-sale service:

*Inquiry and consulting support.

*Sample test support.

*Please check our factory.

2. After-sales service:

*Within 7 days from the date of your local customs clearance: If there is any problem with the machine, we will replace it for you free of charge.

*It has been more than 7 days after the local customs clearance, but during the warranty period, if there is any problem with the machine parts, we can replace the old machine parts with new machine parts for free, but you should pay all the transportation costs.

*If there is any problem with the machine parts, more than one year warranty period, we can provide new machine parts at cost price, and you should also pay all transportation costs.

*We provide 24-hour technical support via phone and email.

*If you have any questions, our technicians can provide you with online remote guidance (Skype / MSN / What is the application / viber / phone / Etc).

*The machine has been adjusted before leaving the factory, and the operation panel has been included when leaving the factory. If there are other questions, please let me know.

*We have manuals and CDs (guide videos) for software installation, operation, and machine use and maintenance.

3. HUNST Laser Technology Co., Ltd. provides free technical training for all customers around the world until the buyer's workers can operate the machine normally and individually. The main training is as follows:

*Train the operation of the control software.

*Train the operation of the on/off device in a standard way.

*Technical parameter description and its setting range.

*Daily cleaning and maintenance of the machine.

*Solutions to common hardware problems.

*Training on other issues and technical suggestions in daily production.

4. Training can be carried out in the following ways:

*Customers' workers can come to our factory to receive the most professional manual training.

*We can send engineers to the customer's country/region to train the workers in the customer's target factory. However, customers should pay for air tickets and daily expenses (such as food and accommodation).

*Remote training via Internet tools (such as Team-viewer, Skype and other instant messaging software).

5.Service hotline

:

24-hour telephone 0086-0769-27223327 0086 13929256735 and e-mail: ht AT hunstlaser.com online technical support.

Hot Searches