NaN / 0

TILI F Series FAF Type High Quality Speed Reducer Efficient and Durable Parallel Shaft Helical Gear Motor for Manufacturing

Get Latest Price

US$ 198

≥2 Pieces

US$ 168

≥10 Pieces

US$ 129

≥100 Pieces

Quick Details

Gearing Arrangement:

Helical

Output Torque:

144-2000NM

Input Speed:

2000-10000RPM

Output Speed:

Based On Your Needs

Product Details

Product Overview

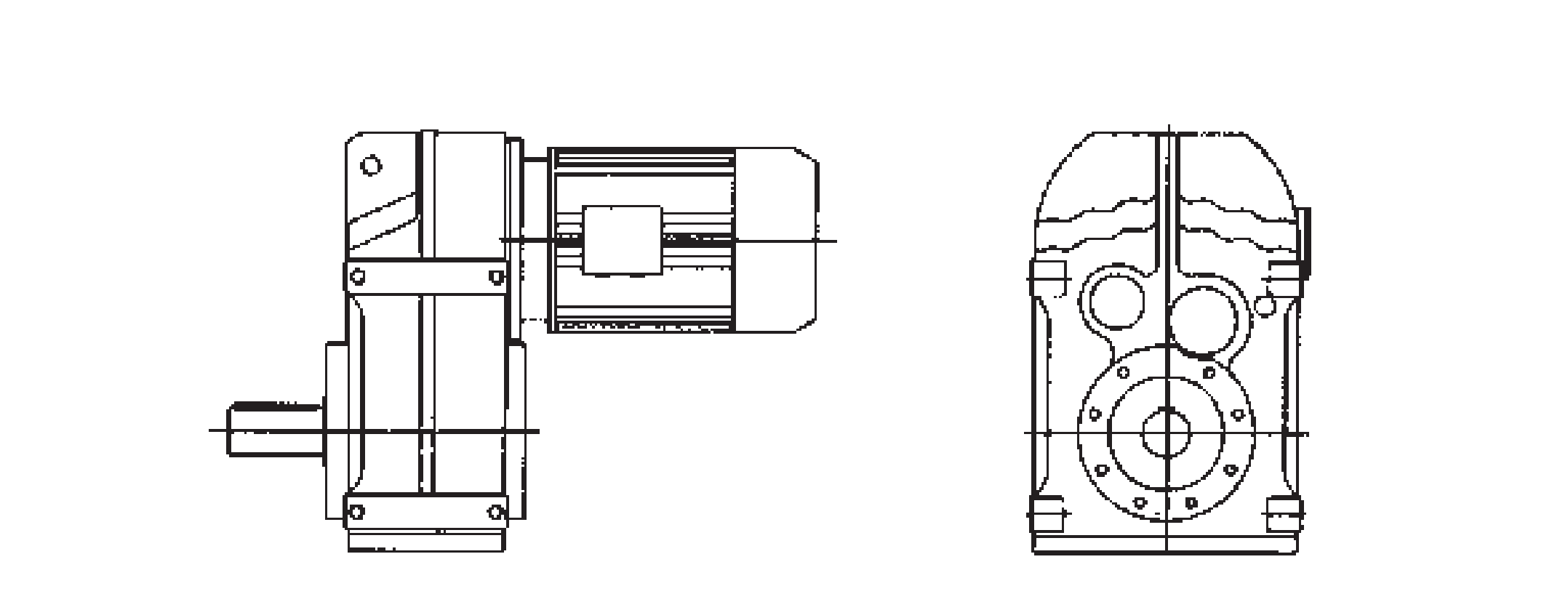

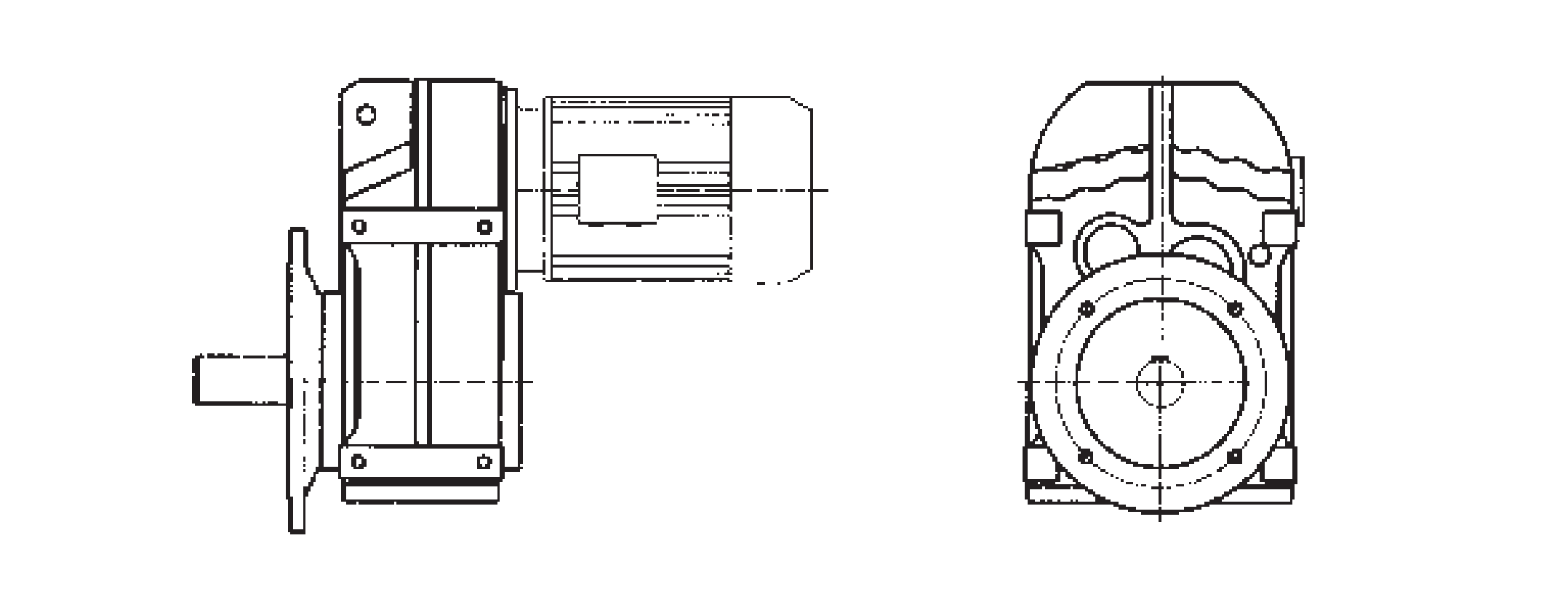

Dimensional Description

Shafts of F series geared motors are all paralled to each other. Units of F series all consist of two or three stages helical gears.

Type F:

Foot mounted. Solid output shaft.

Type FF:

B5 flange mounted. Solid output shaft.

Type FA:

Shaft mounted. Hollow output shaft.

Type FAF:

B5 flange mounted. Hollow output shaft.

Type FAZ:

B14 flange mounted version with hollow

shaft.

Type FH:

Hollow shaft and shrink disk mounted.

Type FHF:

B5 flange mounted version with hollow shaf!and shrink disk.

Type FHZ:

B14 fange mounted version with hollow

shaft and shrink disk.

Type F

AT/FHT:

As altered type from type GFAGFH,this type is added torque arm and other accessories.

Type F..SZ..AD..

:

Input shaft types.

Type F..R:

Combined types of type GF and type GR

Features of Products

1. Highly Standard Modular Designed:

The products are easily connected with and driven by different types of motors or other kinds of input power. The same type geared motor can be adapted to optioned powers of motors. It is therefore easy to realize different solutions for varied requirements.

2. Ratio:

Featured many closely divided ratios and wide range of them, Very big final ratios can be obtained through combined unites lo reach extremely low output speeds.

3. Mounting Arrangement:

No strict limitation to the mounting arrangement.

4

. High strength, Compact Dimension:

Housings are made of high strength cast iron. Gears and shaft gears are finished with gas carburising process and precise grounding to sequentially get high loading capacity of per certain volume.

5. Long Service Life:

Under the condition of accurately selecting type size and the normal maintenance and use main components (except those easily disabled parts )can last as long as up to more than 25,000 hours. Easily-disabled parts include lubricating oil, oil seals, and bearings.

6. Low Noise:

All key components are finished by precisely machining, accurate assembly, and finally tested, and therefore, fairly low noise is reached.

7. High Efficiency:

The efficiency of gear unit can reach 95%, The efficiency of worm gear unit can reach 89%.

8. Large radial loading ability.

9. Axial load ability of up to 5% of radial load.

Site Conditions

The geared motors are suitabie for the operation silesin the ambient temperatures from. 10℃ to 40℃ and altitudes up to 1000m above the sea lever.

They can be used both for clockwise running and anti-clockwise running.

There is no limitation to specific application field.

They can be used both for clockwise running and anti-clockwise running.

There is no limitation to specific application field.

While applied in other aggressive operating atmosphere environment conditions. please contact our technology department.

Description of Selection Tables

1. Selection Table [ Constant Power ]:

Motor Power Pm [ kW ]:

Power is indicated on the basis of Y

2

motor.

Output Speed n

a

[ r/min ]:

Output speed is calculated on the basis of motor's fully loading speed and geared motor's ratio. Unit: revolutions per minute.

Output Torque M

a

[ Nm ]:

Torque available at output shaft while motor being fully loaded. All internal efficiency factors have already considered.

Ratio [i]:

Exact final total transmission ratio from input to output

Permissible Radial Load F

Ra

[ kN ]:

Permissible radial load on the middle point of overhung shaft ( F

Ra

value listed in the table must be multiplied by 0.4, if load is placed on the end point of the shaft ). The mathematic product of actual radial load Fr and actual service factor f

A

should not be bigger than this F

Ra

, i.e. F

Ra

>f

A

*Fr (for f

A-

please see the description of f

B

). Normally, Fr of a working unit can be got through the following:

Fr=Mr*fr/r (N)

where, Mr - working torque of the working unit (Nm)

r - pitch circle radius of the working unit (m)

fr - radial load factor, which can be got refer to the following:

fr=1, for single chain sprocket wheel

fr=1.25, for single gear or for double chain sprocket wheel

fr=1.5, for V-section belt

fr=2.5. for flat bel

t

Service Factor f

B

:

The ratio of rated power of gear uni!to rated power of motor power. it is essential data to select the size and strength of gear unit.

Type Size of Unit:

including type and size. individual unit and combined units are available. Combination is considered commonly under the constant power condition.Each type ( and even some other typos not mentioned in the tables )can be assembled or combined to any ratio mentioned in the tables. For the detailed construction dimension, see the relevant menstonal tables.

Pole Number of Motor:

The pole number of Y

2

motor.

Mass (Weight) [ kg ]:

Not weight of geared unit, without the motor. This weight is only for your general reference.

2. Selection Table ( Constant Torque):

Constant torque selection table is suitable for the conditions where the constant torque system is applied appropriately.If the Max, torque listed in this table is used when calculating.service factor is 1.0, The meanings of other terms are similar to ones described in Selection Table (Constant Power).

Selection Steps

1. Type Selection

Types of units are normally selected by customers to meet transmission mounting arrangement requirement. Series Gand seres GF are applied to the conditions that input shafts are parallel to output shafts. And, series GS and series Gk are applied to the conditions that input shaft are vertical to output shafts.

2. Selection of actual Service Factor f

A

1) Normal requirement

f

A

is determined by load feature, operating hours, starts and stops number per hour of working unit. The normal total combined service factor is calculated as follows:

f

A

=f

Ah

*f

Ac

Where: fAh-the factor determined by load feature and operating hours of per day. See the table of fAh. The other working unit's fAh out of the table could be determined by analogy.

f

Ac

-the factor determined by number of starts and stopper hour of working unit.

Attention:the number should be counted even start or stop.

2) Special requirement

If the ambient temperature is special high, the temperature factor fAt should be considered, refer to the factor fAt column of selection table.

If requiring higher reliability, the security factor fAs should be considered.

When you can't select the value of service factor, contact with us.

3. Selection of Type (size)

It is essential to meet following: f

B

≥f

A

1) For constant power

(1)The motor is mounted directly into gear unit or with coupling

a. Reach to a relevant power and pole number of motor from selection table (constant power)

b. Select rudely a size with close ratio, and record it's f

B

.

c. Compare, if meet this formula: f

B

>f

A

, then this size gear unit is available. Otherwise select a bigger size of gear unit until meet it.

(2) The gear unit with prefixion deceleration unit

When connecting the motor and gear unit using gears, belts or chains, etc, Because the torque of input has been increased, so it is essential to convert motor power into input power of gear unit, the input power is to multiply motor power by radio. Select the size according to the power converted from the selection table. Attention: the number of motor pole is same.

2) For constant torque

Select the size of gear unit according to the power and pole of motor and radio from selection table (constant torque). It is essential to restrict the working torque under maximal torque of gear unit selected.

4. Radial Load checking

It will checking overhang load, if the gears, belts and chains, etc, are fired on the shaft of the gear motors. For checking method, refer to the relevant contents in fore.named description of selection table.

5、Mounting Dimension checking

Check the mounting dimension when there is a limitation to site mounting condition.If the selected type by the above method is appropriate to site mounting condition, this final type is standard and should be written in formal type description. if any speciaa requirement is requested, please describe it while placing order.

Normal Delivery Condition:

1. Motor:

Y

2

motor of protection class lP54 and of insulation class F

1

while no special request. But this insulation class F motor is generally recommended to be used in the condition where the class B is required.

2. Terminal box:

Terminal box is at 0" position if no special request (see description of motor terminal box position).

3. Rotation direction:

There will be no mark of rotation direction for input shaft or output shaft, if the relationship between input shaft and output shaft is not requested.

4

.Lubricants:

Units are supplied with lubricant oil before delivery.

5

. Accessories:

Generally, accessories excluded in mounting dimension table do not belong to our standard supply.

S

erwice Factor F

Ah

|

Application

|

8 hours / day

|

16 hours / day

|

24 hours / day

|

|

Food Industry

Crushers

Beet Slicers, Kneaders Meat Grinders Filling Machines Dough Mixers Extruders Sugar Cane Knives Sugar Roller Mills Toasters |

1.75

1.25

1.25

0.8~1

1

1.25

1.75

1.75

1.25

|

2

1.5

1.5

1

1.25

1.5

1.75

1.75

1.25

|

2.25

1.75

1.5

1.25

1.5

1.75

1.75

1.75

1.25

|

|

Auxiliary Drives, Servicing

Inching,No Load Normal Duty |

0.8-1

1.25

|

1.25

|

1.25

|

|

Compressors

Centrifugal

Lobe

|

1

1

|

1.25

1.25

|

1.5

1.5

|

|

Filters

|

1

|

1.25

|

1.5

|

|

Construction Industry

Cement Mixers

Cement Mills

Mortar Spraying Machine

|

1.25

1.5

0.8~1

|

1.5

1.75

1

|

1.75

2

1.25

|

|

Generators

|

0.8-1

|

1

|

1.25

|

|

Water Treatment, Environment Tools

Aerators

Common Aerators

Carrousel Aerators

Bar Screens, Collectors

Screw Pumps

|

1.75

1.5

1.75

0.8-1

1

|

2.0

1.5

1.75

1

1.25

|

2.0

1.5

1.75

1.25

1.5

|

|

Screens

Rotary(for stone, for gravel)

Traveling Water Intake

|

1

0.8-1

|

1.25

1

|

1.5

1.25

|

|

Agricultural Machinery

Manure Scrapers

Harvesting machines

|

0.8-1

0.8-1

|

1

1

|

|

|

Cranes and Hoists

Travel Gears

Slewing Gears

Hoisting Gears

Derricking Jib Cranes

|

1.5

125

1.25

1.25

|

1.75

1.5

1.5

1.5

|

2.0

2.0

1.75

1.75

|

|

Mixers

Constant Density

Variable Density

|

1.25

1.5

|

1.5

1.75

|

1.5

1.75

|

|

Lumber and Plastic Industry

Main Drive for Saws

Feed Drive for Saws

Chopping Machines

Veneer Gluing Machines

Drilling Machines

Extruders

|

1.5

1

1.5

0.8-1

0.8-1

1.25

|

1.75

1.25

1.75

1

1

1.5

|

2

1.5

2

1.25

1.25

1.75

|

|

Agitators

Pure Liquids (Constant Density)

Liquids with Variable Density

Liquids and Solids

|

1.25

1.5

1.5

|

1.5

1.75

1.75

|

1.5

2.0

2.0

|

|

Mills

Ball, Rod

Hammer, Desintegrator

|

1.75

1.5

|

1.75

1.75

|

1.75

2

|

|

Printing and Paper Techniques

Cutters

Reels

Bale Feeders

|

1

0.8-1

1

|

1.25

1

1.25

|

1.5

1.25

1.25

|

|

Elevators

Bucket Elevators

Freight Elevalors

Escalators

|

1.25

1.25

1.25

|

1.5

1.5

1.25

|

1.75

1.75

1.5

|

|

Textile Industry

Looms

Spinners

Washers

|

1.25

0.8-1

1

|

1.5

1

1.25

|

1.75

1.25

1.5

|

|

Conveyors

Bucket Conveyors

Uniformly Loaded or Fed

Heavy Duty, Chain & Screw Conveyors

Shaker Conveyors

Hoists

Belt Conveyors

Hauling Winches

|

1.5

0.8-1

1.25

1.5

1.5

1.25

1.5

|

1.75

1

1.5

1.75

1.75

1.5

1.75

|

1.75

1.25

1.5

2

1.75

1.5

1.75

|

|

Apron Conveyors

|

1.25

|

1.25

|

1.5

|

|

Fans

Centrifugal

Industrial Fans

Cooling Tower Drivers

Cooling Tower Fans

|

0.8-1

1

1.75

1.75

|

1

1.25

1.75

2.0

|

1.25

1.5

1.75

2.0

|

|

Packing Machine

Cardboard Stacking Machine

Wrapping Machine

|

1.25

0.8-1

|

1.5

1

|

1.75

1.25

|

|

Machine tools

Plate Surfacers, Plate Planers, Bending Rolls

Main Drives, Feed Drives

Feed and Auxiliary Drive

Presses

Folding Machines

Plate Shears

|

1.25

1

0.8-1

1.75

1.5

1.75

|

1.5

1.25

1

2

1.75

2

|

1.75

1.5

1.25

2

2

2

|

|

Iron and Steel Industry

Wire Draw Benches

Winding Machines

Rolling Mill: Non Reversing

- Group Drives

- Individual Drives

|

1.25

1 25

1.25

1.5

|

1.5

1.75

1.5

1.75

|

1.75

1.75

1.75

2

|

|

Pumps

Centrifugal

Rotary, Gear Type, Lobe, Vane

Piston Pumps: Single Cylinder

Multi Cylinder

Screw Pumps

|

1

0.8-1

1.5

1.25

1

|

1.25

1

1.75

1.5

1.25

|

1.5

1.25

2

1.75

1.5

|

Service Factor f

AC

|

Number of Starts and Stop / Hour

|

|

|

<10

|

1

|

|

<100

|

1.15

|

|

<500

|

1.25

|

Service Factor f

At

|

Ambient Temperature

|

+20℃···

|

+20℃···+30℃

|

+30℃···+40℃

|

+40℃···+50℃

|

+50℃···+60℃

|

|

f

At

|

1

|

1.1

|

1.25

|

1.5

|

1.75

|

Hot Searches