NaN / 0

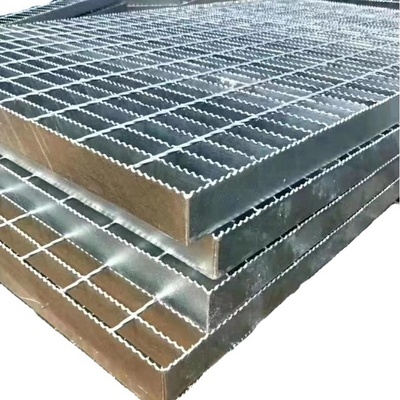

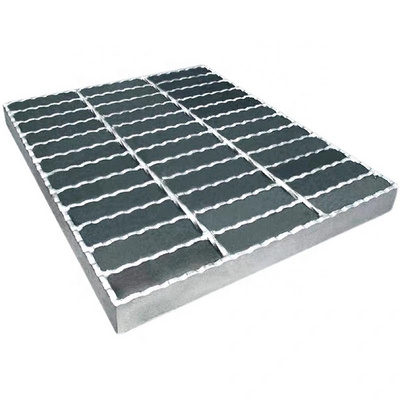

Light Steel Structure Hot Dipped Galvanized Serrated Flat Steel Grating Bar Welded HDG Grating Panel

Get Latest Price

US$ 17.9

≥2 Square meters

US$ 12.3

≥1000 Square meters

Quick Details

Warranty:

1 Year

After-sale Service:

NONE

Project Solution Capability:

NONE

Application:

Warehouse

Product Details

Product Description

Steel grating is also called steel frame lattice or steel grid plate: It is usually made of Q235 (low carbon steel) stainless steel. It is a kind of steel product that has square lattice made by welding flat steel and bar that are crossed and arranged in certain space. It is mainly used as drain cover, steel structure platform board, ladder tread, etc. The bar is usually twisted square steel (twisted steel)

Steel grating production standard:

| Steel grating standard | Steel standard | Hot dipping zinc standard |

| China YB/T4001.1-2007 (latest standard) | China GB700-88 | China GB/T13912-92 |

| US ANSI/NAAMM (MBG531-93) | US ASTM(A36) | US ASTM(A123) |

| British BS4592-1:1995 | British BS360(43A) | British BS729 |

| Australian AS1657-1992 | Australian AS3679 | Australian AS1650 |

| Series | Flat steel space | Bar space | Load flat steel specification (width * thickness) | |||||

| 20×3 | 25×3 | 32×3 | 40×3 | 20×5 | 25×5 | |||

| 1 | 30 | 100 | G203/30/100 | G253/30/100 | G323/30/100 | G403/30/100 | G205/30/100 | G255/30/100 |

| 50 | G203/30/50 | G253/30/50 | G323/30/50 | G403/30/50 | G205/30/50 | G255/30/50 | ||

| 2 | 40 | 100 | G203/40/100 | G253/40/100 | G323/40/100 | G403/40/100 | G205/40/100 | G255/40/100 |

| 50 | G203/40/50 | G253/40/50 | G323/40/50 | G403/40/50 | G205/40/50 | G255/40/50 | ||

| 3 | 60 | 50 |

G203/60/50

|

G253/60/50 | G253/60/50 | G403/60/50 | G205/60/50 | G255/60/50 |

| Series | Flat steel space | Bar space | Load flat steel specification (width * thickness) | |||||

| 32×5 | 40×5 | 45×5 | 50×5 | 55×5 | 60×5 | |||

| 1 | 30 | 100 | G325/30/100 | G405/30/100 | G455/30/100 | G505/30/100 | G555/30/100 | G605/30/100 |

| 50 | G325/30/50 | G405/30/50 | G455/30/50 | G505/30/50 | G555/30/50 | G605/30/50 | ||

| 2 | 40 | 100 | G325/40/100 | G405/40/100 | G455/40/100 | G505/40/100 | G555/40/100 | G605/40/100 |

| 50 | G325/40/50 | G405/40/50 | G455/40/50 | G505/40/50 | G555/40/50 | G605/40/50 | ||

| 3 | 60 | 50 | G325/60/50 | G405/60/50 | G455/60/50 | G505/60/50 | G555/60/50 | G605/60/50 |

features

1. High strength, light structure: solid grid pressure welding structure has advantages of high load, light structure, easy installation, etc.

2. Fine appearance, durable in use: hot zinc dipping surface treatment makes it own fairly good corrosion resistance, bright and beautiful surface.

3. Good ventilation, lighting, thermal, anti-explosion, and anti-skid performance.

4. Prevent dirt deposition.

Category

Divided by welding method:

Pressure welding type, inlaid type, lock penetration type and weld penetration type.

Divided by the shape of load flat steel side:

Flat type, tooth type, and I shape, etc

Divided by material:

Stainless steel grating and carbon steel grating

The surface treatment can be hot galvanizing, cold galvanizing (electric galvanizing), paint spraying, antirust oil soaking, dipping, plastic spraying, and no treatment.

Product process:

Application:

It is widely used for platform, aisle, trestle, drain cover, manhole cover, steel ladder, fence, and guardrail in the fields including petrochemical, power station, sewage treatment plant, mechanical manufacture, mechanical and electrical equipment, paper mill, cement plant, pharmacy, food processing, municipal engineering, environmental engineering, etc .

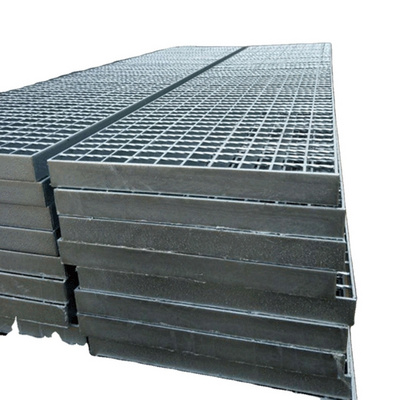

Packaging & Shipping

With Steel Belt and wrapped with plastic film or as customers' requirement.

Hot Searches