NaN / 0

AMS 4544 Annealed Nickel-Copper alloy Monel 400 strip monel Alloy 400 wire/bar/plate/tube price per kg for Oil & Gas Extraction

Get Latest Price

US$ 28

≥5 Kilograms

US$ 25

≥100 Kilograms

US$ 20

≥500 Kilograms

Quick Details

Application:

Gasoline and water tanks, Marine and Chemical Processing Equipment

Place of Origin:

Jiangsu, China

Brand Name:

DZX

Model Number:

Monel 400

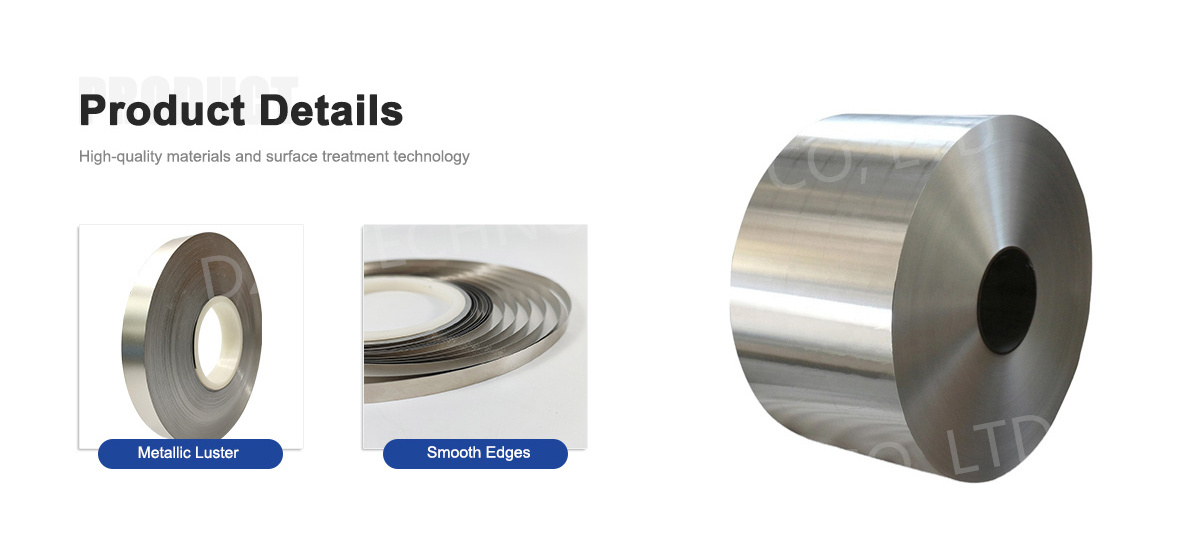

Product Details

Products Description

Specification:

|

Place Of Origin

|

Jiangsu China

|

|

Package

|

Bundle up

|

|

Technique

|

Finish Rolling / Cold Drawing / Bright Annealing

|

|

Customized

|

Customized packaging/size

|

|

Name

|

Monel400 ( UNS N04400 2.4360 2.4361 M35-1 )

|

|

|

||

|

Chemical

Compsition Wt.%

|

Ni

|

min.63

|

max.-

|

||

|

|

Cu

|

min.28

|

max.34

|

||

|

|

C

|

min.-

|

max.0.3

|

||

|

|

Mn

|

min.-

|

max.2

|

||

|

|

Si

|

min.-

|

max.0.5

|

||

|

|

Fe

|

min.-

|

max.2.5

|

||

|

|

S

|

min.-

|

max.0.01

|

||

|

|

P

|

min.-

|

max.0.024

|

||

|

Physical Constants

|

|

|

||

|

|

|

|

||

|

Density.g/cm³

|

8.83g/cm³

|

|

||

|

MeltingRange

|

1300-1390℃

|

|

||

|

MechanicalConstants

|

Alloy State

|

Monel400 ( UNS N04400 2.4360 2.4361 M35-1 )

|

||

|

|

MPA Rm N / mm2

|

480

|

||

|

|

MPA RP0.2N / mm2

|

170

|

||

|

|

A5%

|

35

|

||

|

Characters

|

Monel 400 is the most versatile and comprehensive corrosion resistaant alloy. This alloy has excellent corrosion resistance in

hydrofluoric acid and fluorine gas media , and also has excellent corrosion resistance to hot concentrated alkali liquids . At the same time ,it is also resistant to corrosion of neutral solutions ,water ,seawater ,atmosphere, organic compounds , etc. An important feature of the alloy is that it generally does not produce stress corrosion cracks and has good cutting performance. |

|

||

Monel 400/k500 strip

Monel400 is a corrosion-resistant alloy with the largest amount, the most versatile and excellent comprehensive performance. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance to hot concentrated lye. At the same time, it is resistant to corrosion from neutral solutions, water, seawater, air, organiccompounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracks and has good cutting performance.

The chemical composition of Monel400 alloy is mainly composed of 30% Cu and 65% Ni plus a small amount of Fe (1%-2%). Due to the difference in chemical composition, it can have a variety of alloy grades, but there is no significant difference in corrosion resistance between them. Monel400 alloy is more resistant to corrosion by reducing media than pure nickel, and more resistant to corrosion by oxidizing media than pure copper.

National standards and generic names: MONEL400, ASTM B127, ASME SB-127, AMS 4554, JIS NW4400

The chemical element composition of Monel400 alloy: C: ≤0.3, Si: ≤0.50, Mn: ≤2.0, Ni: ≥63, Cu: 28~34, S: ≤ 0.024, Fe ≤ 2.5, unit:%

Folding matching welding consumables Monel Monel400 welding rod (ENiCu-7), Monel400 welding wire (ERNiCu-70) Folding use Marine heat exchangers, seawater desalination equipment, salt production equipment, marine and chemical processing equipment, propeller shafts and water pumps, gasoline and water tanks, etc.

Monel400 is a corrosion-resistant alloy with the largest amount, the most versatile and excellent comprehensive performance. This alloy has excellent corrosion resistance in hydrofluoric acid and fluorine gas media, and also has excellent corrosion resistance to hot concentrated lye. At the same time, it is resistant to corrosion from neutral solutions, water, seawater, air, organiccompounds, etc. An important feature of this alloy is that it generally does not produce stress corrosion cracks and has good cutting performance.

The chemical composition of Monel400 alloy is mainly composed of 30% Cu and 65% Ni plus a small amount of Fe (1%-2%). Due to the difference in chemical composition, it can have a variety of alloy grades, but there is no significant difference in corrosion resistance between them. Monel400 alloy is more resistant to corrosion by reducing media than pure nickel, and more resistant to corrosion by oxidizing media than pure copper.

National standards and generic names: MONEL400, ASTM B127, ASME SB-127, AMS 4554, JIS NW4400

The chemical element composition of Monel400 alloy: C: ≤0.3, Si: ≤0.50, Mn: ≤2.0, Ni: ≥63, Cu: 28~34, S: ≤ 0.024, Fe ≤ 2.5, unit:%

Folding matching welding consumables Monel Monel400 welding rod (ENiCu-7), Monel400 welding wire (ERNiCu-70) Folding use Marine heat exchangers, seawater desalination equipment, salt production equipment, marine and chemical processing equipment, propeller shafts and water pumps, gasoline and water tanks, etc.

Product Details

Production Process

Packing Deatils

Application

The application areas of monel strip include the following:

Monel strip is a high-performance alloy strip composed of elements such as nickel, copper, iron, and carbon. It has excellent corrosion resistance, high strength, high temperature resistance, and good processability, so it is widely used in many fields, including:

Chemical industry:

Monel strips are commonly used in the manufacturing of corrosion-resistant equipment such as

chemical equipment, petroleum and natural gas processing equipment, acid and alkali storage tanks, reactors, pipelines, and valves. Offshore engineering: Monel strips are commonly used in seawater coolers, seawater desalination equipment, offshore Oil platform, etc. in offshore engineering because of their excellent seawater corrosion resistance.

chemical equipment, petroleum and natural gas processing equipment, acid and alkali storage tanks, reactors, pipelines, and valves. Offshore engineering: Monel strips are commonly used in seawater coolers, seawater desalination equipment, offshore Oil platform, etc. in offshore engineering because of their excellent seawater corrosion resistance.

Aerospace industry:

Monel strip has high strength and high temperature resistance, and is commonly used in engine parts, gas turbines, jet engine nozzles, etc. in the aerospace field. devices: Monel tape has good biocompatibility and corrosion resistance, and is commonly used in device manufacturing, such as Artificial heart valves, surgical instruments, etc.

Electronic industry:

Due to its excellent conductivity and corrosion resistance, Monel strips are commonly used in electronic components, electronic circuits, battery electrodes, etc.

Food processing industry: Monel strips have good corrosion resistance and high temperature resistance, and are commonly used in food processing equipment, food storage equipment, etc. In summary, Monel strips have wide applications in fields such as chemical, marine, aerospace, electronic, and food processing.

Food processing industry: Monel strips have good corrosion resistance and high temperature resistance, and are commonly used in food processing equipment, food storage equipment, etc. In summary, Monel strips have wide applications in fields such as chemical, marine, aerospace, electronic, and food processing.