NaN / 0

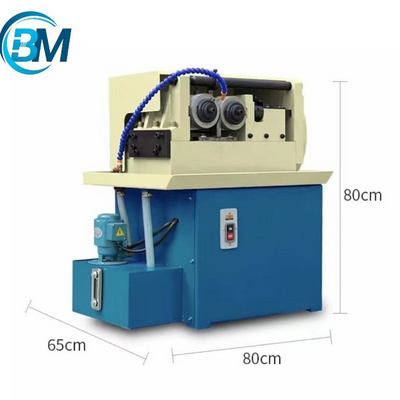

scaffolding pipe thread rolling pipe nipple tube Thread and profile rolling machines knurling machine threading machine pipe

Get Latest Price

US$ 12000

≥1 Sets

US$ 8000

≥5 Sets

Quick Details

Place of Origin:

Guangdong, China

Application:

connectors, bicycles, auto parts

Production Capacity:

4-25(pcs/min)

Brand Name:

TOBEST

Product Details

Product Overview

Advantages

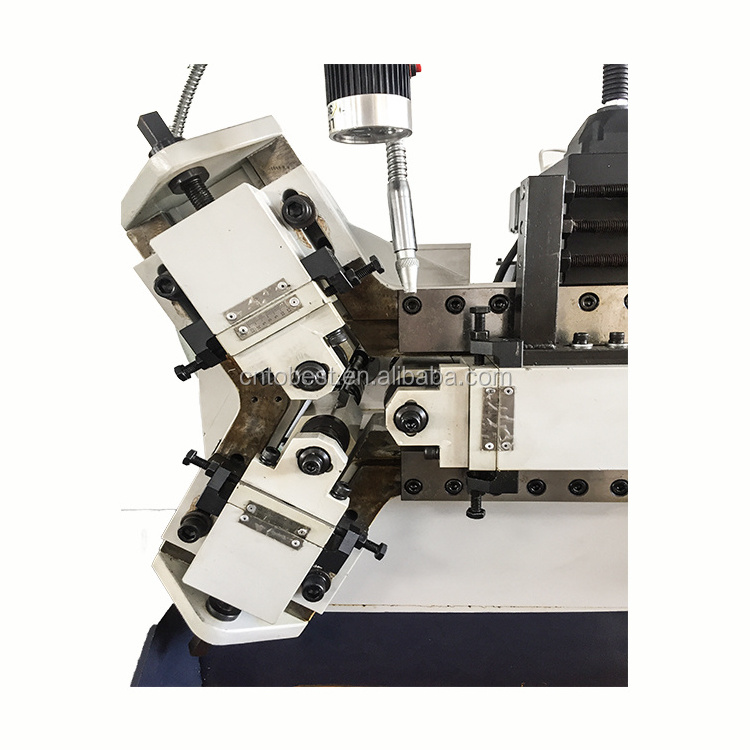

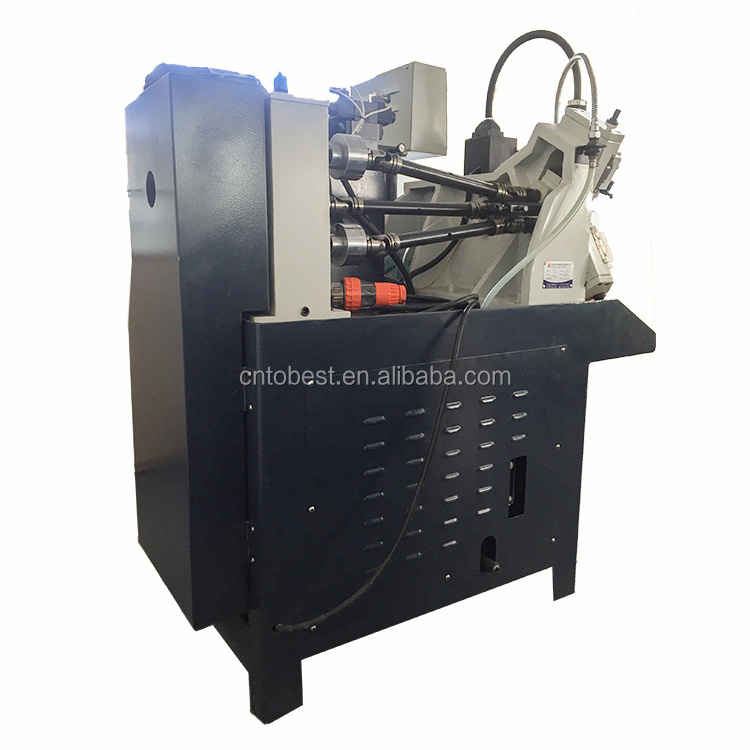

1.Designed specially for small full-thread tube-type parts, easy to operate.

2.The spindle is controlled by frequency converter, the rotation speed can be adjusted as you want.

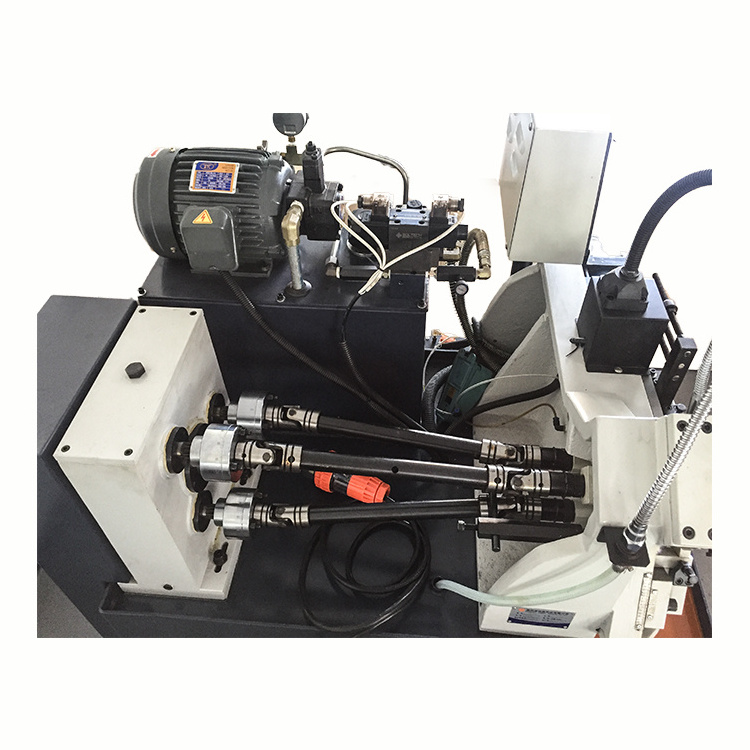

3.Adopt hydraulic circuit control for feeding, so the tool forward smoothly, easy to operate.

4.With heating treatment for driving gear with lower noise and high wear resistance

5.Suitable for the industries like connector, bicycle, auto fittings and oil tube joint, etc

2.The spindle is controlled by frequency converter, the rotation speed can be adjusted as you want.

3.Adopt hydraulic circuit control for feeding, so the tool forward smoothly, easy to operate.

4.With heating treatment for driving gear with lower noise and high wear resistance

5.Suitable for the industries like connector, bicycle, auto fittings and oil tube joint, etc

FEATURES AT A GLANCE

HIGH PRECISION

HIGH STABILITY

SIMPLE CONTROL

EASY MAINTENANCE

Application

PRODUCT SPECIFICATIONS

|

Diameter rang

|

18-60mm

|

Outside diameter of rolling dies

|

90-130mm

|

|

Pitch rang

|

10.-4.0p

|

Inside diameter of rolling dies

|

40mm

|

|

Max length of the threads

|

50mm and thru-feed

|

Max thickness of rolling die

|

50mm

|

|

Rotation speed

|

90/160/235/340 r/min

|

Output

|

4-25pcs/min

|

|

Machine motor

|

3.75KW

|

Hydraulic motor

|

2.2kw

|

|

Max rolling pressure

|

12tons

|

Machine weight

|

1270KG

|

|

Gross weight

|

1350KG

|

Packing size

|

1700*1600*1700mm

|

|

Max center distance between die spindles

|

190mm

|

Min center distance between die spindles

|

105mm

|

Hot Searches