NaN / 0

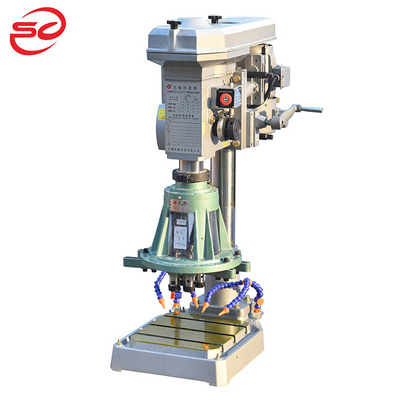

Tapping Drilling And Tapping Machine Bench Industrial Pillar Drilling Machine Gear Type

Get Latest Price

US$ 7000

≥1 Pieces

US$ 6800

≥100 Pieces

Quick Details

type:

Drilling tapping integrated machine

Max. Drilling Dia. (mm):

25

Range of Spindle Speed(r.p.m):

365 - 3150 r.p.m

Place of Origin:

China

Product Details

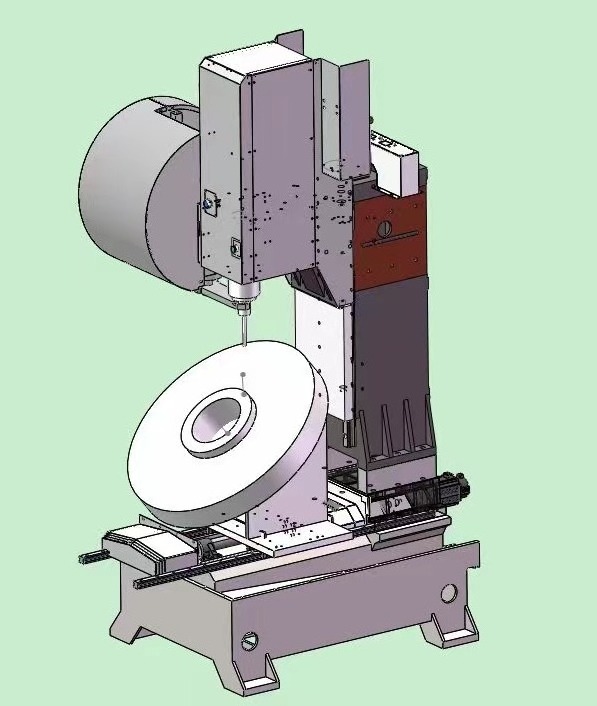

ZK-25S vertical CNC drilling and tapping machine tool technical description quotation

I. Overall layout and use of machine tools

Two, machine tool characteristics

Iii. Standard functions of DF-10T controller

Four. ZK-25S vertical CNC drilling and tapping machine standard configuration

V. Main specifications and technical parameters

Vi. Supply list

Seven, random annex list

8. The machine tool has been selected and configured

9. List of the main purchased parts of the equipment

Ten, installation and debugging

Xi. Machine tool acceptance

Xii. Equipment after-sales service and warranty provisions

Xiii. Enterprise credit qualification documents

Two, machine tool characteristics

1. The machine is made of box structure design and manufacture, appropriate annealing treatment, eliminate internal stress, tough material, coupled with box structure design, high rigid body structure, so that the machine has enough rigidity and strength to show the characteristics of high cutting ability and high precision.

2. Adopt high precision ball screw, with the pre-tension design of both ends of the support seat, can eliminate the transmission backlash and pre-compensate the error caused by temperature rise, to ensure positioning accuracy.

3. Spindle motor: The machine adopts high speed servo motor, the motor is free warranty for 1 year, so that the machine has a very good performance in high speed, low speed and light and heavy cutting (power of 3.7KW).

4. Spindle head: high precision, high rigidity of the spindle head, the system uses triple angular contact bearing, it can withstand radial and axial load of high speed. High precision machining, and can maintain high precision machining.

5. Electrical box: the electrical box is equipped with a heat exchanger to dissipate heat easily to ensure the stability of the system. The external wiring part has a protective coil, which can resist heat and oil and water.

6. Lubrication system: the machine automatic de-pressure lubrication system centralized oil supply, with advanced de-pressure intermittent oil supply system, timing, quantitative, fixed pressure, individual way to provide each lubrication point timely, appropriate amount of oil to ensure that each lubrication position is correct to get lubricating oil, so that the machine long time operation without future care.

7 Fully dense plate gold: in today's environmental protection and operator safety considerations under the strong requirements, fully sealed plate gold design, completely prevent the cutting fluid and cutting fluid splashed outside the machine tool, so that the surrounding machine tool can be kept clean.

Iii. Standard functions of the controller

1. Single-axis control of the control system

2. The number of linkage axes is 1 axis

3. The minimum set unit is 0.0001/0.00001in

4. Max instruction value ±9

5. The minimum unit of movement is 0.001

6. Automatic identification of tape code EIA/ISO

7. Fast feed rate F0, 25, 50, 100

8. Manual feed rate 0~200%

9. Feed rate command directly input mm/min

10. Feed rate percentage 0~200%

11. Cut G01 straight

12. Fast feed G00

13. Multi-quadrant circular arc cutting G02/ G03

14. Pause G04

15. Single program segment

16. Run empty

17. The program is starting

18. Tool diameter correction G41, G42/G40

19. Tool length correction G43, G44/G49

20. User macros

21.8 "LED display screen

22. Hand wheel feed 2/3UNIT

23. Incremental feed ×1, ×10, ×100, ×1000

24. Read tape/play tape interface RS232

25. The automatic reference point returns to G28

26. The reference point returns to confirm G27

27. Polar interpolation G16

28. Pause G04

29. Memory travel risk display

30. External setting of travel limit

31. Battery alarm output

32. Jump function

33. Screw backlash compensation

34.MDI operation functions

35. Program number O-4 digits

36. Programmable data input

37. Self-diagnostic function

38.RESET

39. Emergency stop function

40. Status display function

41. Programmable logic control PMC-L

42. Embedded Ethernet

43. Decimal point input

44. Coordinate system Settings

45. English/Metric conversion

46. Drilling process cycle G83

47. Rigid tapping cycle

48.M function

49.S function S-5 digits

50. Spindle head actual rotation number display

51.T Function T- 2-digit tool instruction

52. The number of tool compensation memory groups is 64

53. Workpiece program memory capacity 512KB

54. Program number search

55. Language Display (Chinese)

56. Run time/workpiece count display

57. Knife number display

58.RS232

Four, ZK-25S vertical CNC drilling and tapping machine configuration table

1.DF-10T control system

2. Automatic lubrication system

3. Half cover type guard

4. Single axis sliding rail telescopic guard

6. Electrical box heat exchanger

7. Fixed handwheel device

8. System operating instructions

9. Toolbox

10. Working light and warning light

Q1. What is your terms of packing?

A: Generally, we pack our goods in neutral cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: 1)As for sample order T/T or western union 100% before delivery!

2)As the bulk order T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 3-7 days after receiving your advance payment. The specific delivery time depends on the how

processing of the drawing and the quantity of product.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.we also accept the sample order too.

A: Generally, we pack our goods in neutral cartons. If you have legally registered patent, we can pack the goods in your branded boxes after getting your authorization letters.

Q2. What is your terms of payment?

A: 1)As for sample order T/T or western union 100% before delivery!

2)As the bulk order T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q3. What is your terms of delivery?

A: EXW, FOB, CFR, CIF.

Q4. How about your delivery time?

A: Generally, it will take 3-7 days after receiving your advance payment. The specific delivery time depends on the how

processing of the drawing and the quantity of product.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.we also accept the sample order too.

|

|

|

|

|

|

||||

Hot Searches