NaN / 0

ZXSMART Automatic Filling Olive Oil Cooking Oil 8 Head Piston Filler Bottle Filling Machines

Get Latest Price

US$ 13230

≥1 Pieces

US$ 10672

≥4 Pieces

Quick Details

Machinery Capacity:

4000BPH, 500BPH, 2000BPH, 1000BPH, 200BPH

Packaging Material:

Plastic, Metal

Filling Material:

Beer, Milk, Water, Oil, Juice, Edible oil, Engine oil

Filling Accuracy:

±1%

Product Details

Automatic Cooking Oil Piston Bottle Filling Machine

Products Description

Introduction:

The oil filling machine is suitable for filling viscous,inviscid liquid.It's widely applied in food industry ,such as edible oil, juice,and peanut butter. It adopts linear type filling,electromechanical & instrucmental intergration control. Easy to operate, auto clean system, multi-function, it can change different bottles or material at any time.

Main configuration:

1. Frame, foot and guardrail materials: aluminum profile, 304 stainless steel

2. Pneumatic components: Taiwan brand AIRTAC

3. Program controller: German brand Siemens

4. Man machine interface: German brand Siemens 7-inch color touch screen

5. Photoelectric sensor: German brand Leuze

6. Relay and air switch: French brand Schneider

7. Motor frequency converter: German brand Siemens

8. Materials of exposed parts: aluminum profile, stainless steel, anodized aluminum alloy, electroplated 45 steel and plastic parts

|

Technical Paramrters

|

|

|

|

|

||||

|

Customized solution: Automatic piston filling machine / Flowmeter filling machine

|

|

|

|

|

||||

|

Suitable material

|

Suitable bottle

|

Filling range

|

Filling head

|

Filling capacity

|

||||

|

Edible oil, Wine, Beverage, Jam, peanut butter

|

PP, PET, PE, Plastic, Glass, Round/Square bottle, etc

|

100-1000ml

500-5000ml

|

4-16 heads(can be customized

|

15-70 bottles/min (according to bottle size and the numbers of filling heads)

|

||||

|

Control system

|

Filling precision

|

Voltage

|

Material box

|

Protect system

|

||||

|

PLC+ Touch screen

|

±1%

|

2-4KW, 220V

|

200L(with liquid switch)

|

Alarm light and sound

|

||||

|

Filling valve

|

Fast filling speed, accurate quantitative control of flow and controlled by servo motor

|

|

|

|

||||

|

Cap rotating method

|

Electric control cap pressing, with high efficiency, can press bottle caps with different diameters and heights

|

|

|

|

||||

|

Labeling method

|

Round bottle labeling or Square bottle single/double size labeling

|

|

|

|

||||

|

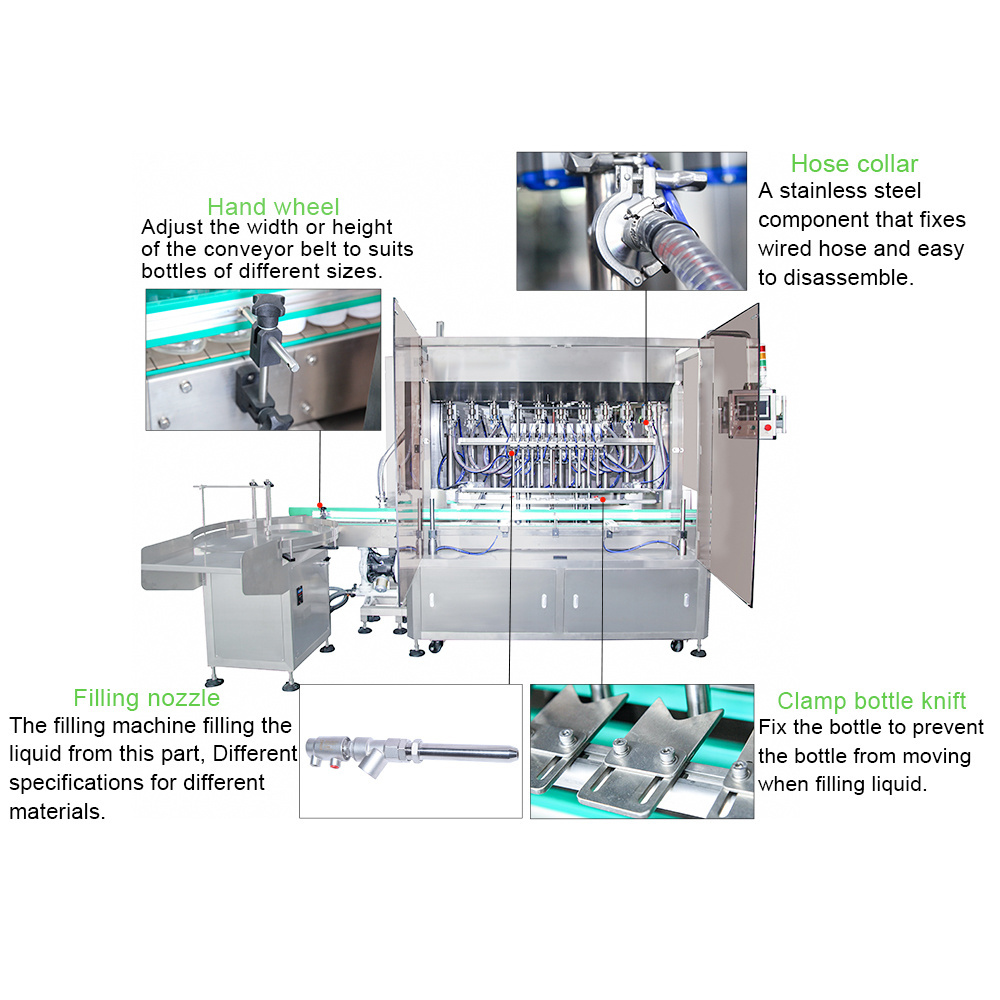

Bottle replacement

|

Just adjust the width of the conveyor belt guardrail and the height of the filling nozzle, simple and convenient

|

|

|

|

||||

|

Materials of liquid contacting parts such as filling nozzle and chute: 316 stainless steel, PTEF

|

|

|

|

|

||||

Details Images

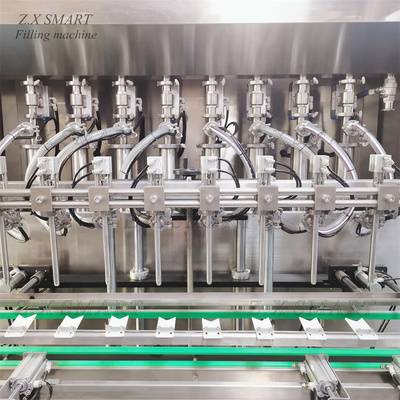

Filling head

10 heads with anti drip and gravity type design, one set can simultaneously fill 10 bottles or 20 bottles, improving production efficiency, and adopting the method of filling while lifting to reduce bubbles. Each nozzle can be individually controlled, and the shape is also varies according to the characteristics of the material.

Touch screen

Siemens operation touch screen makes machine data clear, easy to adjust, and easy to control with just one click. Equipped with a stop button to protect the safety of workers and machines, and equipped with a complete alarm system.

Adjustable handwheel

Equipped with multiple adjustable handwheels to adjust the machine's each part for the production of different bottles. It makes the process of replacing bottles of different shapes easier and more convenient.

Electric sensor

Adopting imported Leuze sensor. Although small in size, it has multiple functions, real-time monitoring of bottle packing, improving production efficiency and quality, and reducing operating costs.

Recommend Products

Hot Searches