NaN / 0

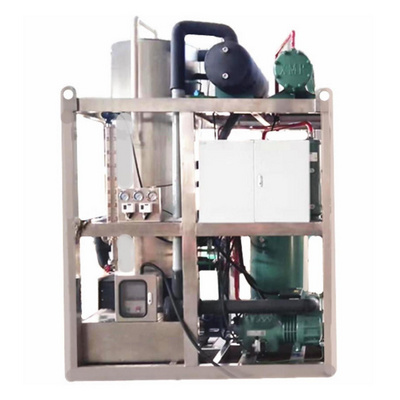

Particle Blasting Granulated Granulator Maquina Fabrica De Hielo Seco Small Dry Ice Block Maker Make Machine

Get Latest Price

US$ 4999

≥1 Sets

US$ 4599

≥4 Sets

US$ 4299

≥21 Sets

Quick Details

Ice Shape:

dry ice

Voltage:

220v/380v

Power:

3kw

Ice storage capacity:

customizable

Product Details

Product Description

Introduction

Dry ice pelletizer is a piece of equipment specially used to manufacture dry ice pellets. It can convert liquid carbon dioxide (CO2) into dry ice pellets to meet the needs of low-temperature freezing, preservation, special effects and cleaning in different industries and application fields.

Application

The dry ice produced by the dry ice pelletizer is suitable for frozen food, vegetables and seafood, cold drinks, stage effects, biological samples, equipment cleaning, etc.

Suitable for food processing plants, hospitals and laboratories, film and stage productions, cleaning and maintenance services, scientific research, special transportation needs, etc.

Features

1. The fuselage is made of stainless steel and has a fully enclosed design, which makes the equipment more integrated, reduces the noise when the equipment is working, and prevents dangers caused by accidental touching by personnel during work.

2 . The hydraulic pump station and particle forming module are both built-in, which on the one hand reduces the equipment’s footprint and on the other hand avoids the impact of dust in dry ice production.

3 . Touch-sensitive LCD panel operation allows you to set the number of purges, working hours, etc. of the hydraulic cylinder, reducing the error rate of manual operations.

4 . The hydraulic system can be equipped with food-grade configuration (using stainless steel parts and edible food oil as the hydraulic transmission medium).

Parameter

| Model | Production capability | Dry ice specification | The density of dry ice | Liquid and solid co2 conversion ratio | The total power | Equipment weight | Overall dimensions |

| GD-DIPM50 | 40-50 kg/h | Φ3mm,Φ16mm | 1550kg/m³ | ≥42% | 3kw | 175kg | 100×48×102cm |

| GD-DIPM100 | 100kg/h |

Φ3mm,Φ10mm,

Φ16mm,

|

1550kg/m³ | ≥42% | 4kw | 380kg | 145×60×142cm |

| GD-DIPM120 | 120-180kg/h | 125×105×70/80mm | 1450-1550kg/m³ | ≥42% | 4.5kw | 360KG | 128×56×134cm |

| GD-DIPM150 | 150kg/h |

Φ3mm,

Φ16mm,

Φ19mm |

1550kg/m³ | ≥42% | 7.5kw | 3600kg | 165×65×168cm |

| GD-DIPM300 | 300-350kg/h |

Φ3mm,

Φ16mm,

Φ19mm |

1550kg/m³ | ≥42% | 8kw | 1100kg | 165×115×168cm |

| GD-DIPM500 | 500-550kg/h |

Φ3mm,

Φ16mm,

Φ19mm |

1550kg/m³ | ≥42% | 18.5kw | 1650kg | 178×135×180cm |

FAQ

Q1. What are the storage conditions for dry ice pellets?

Dry ice should be stored in a dedicated insulated container, usually an insulated package or dry freezer. This helps extend the life of the dry ice and prevents it from evaporating prematurely

Q2. What is the shelf life of dry ice pellets?

Dry ice usually has a relatively short shelf life because it slowly evaporates into CO2 gas. Generally, dry ice can be stored at room temperature for a few hours, but it can last longer in a dry freezer.

Q3. How to dispose of dry ice pellets that are no longer needed?

Unwanted dry ice pellets should be disposed of with caution. The best way is to put it in a ventilated place to ensure the safe release of CO2 gas, and do not discard it in a sealed container.

Q4. Is the operation of the dry ice pelletizer complicated?

The operation of a dry ice pelletizer is relatively simple, but requires experience and training to ensure safety and quality of produced dry ice.

Q5. What should we pay attention to when transporting dry ice pellets?

When transporting dry ice pellets, make sure the container is well sealed to prevent CO2 gas from leaking. At the same time, avoid contacting dry ice with flammable substances or oxygen to prevent safety issues.

Packaging & Shipping

Installing waterproof membrane to reduce dust and water pollution

Standard wooden boxes are used as outer packaging to reduce bumps in international transportation

Delivery Time

For stock type, we can send within 48hrs after confirming order.

For customized type , delivery date need to be negotiated before taking order.

Hot Searches