composites.

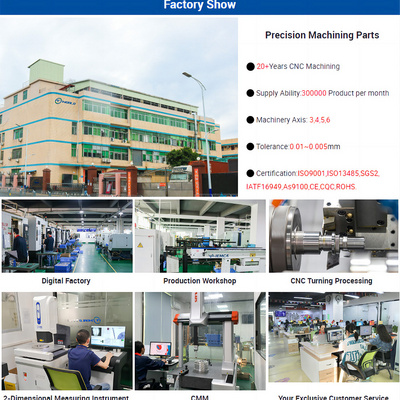

Machinery Axis: 3,4,5,6

Tolerance: +/- 0.01 mm

Special Areas : +/-0.005 mm

Surface Roughness: Ra 0.1~3.2

Supply Ability: 300000 Piece/Month

|

Processing

|

CNC Turning, CNC Milling, Laser Cutting, Bending, Spining, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding

|

|

|

|

|||

|

Materials

|

Aluminum: 2000 series, 6000 series, 7075, 5052, etc.

|

|

|

|

|||

|

|

Stainlesss steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc.

|

|

|

|

|||

|

|

Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc.

|

|

|

|

|||

|

|

Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper

|

|

|

|

|||

|

|

Titanium: Grade F1-F5

|

|

|

|

|||

|

|

Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc.

|

|

|

|

|||

|

Surface Treatment

|

Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickl/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc.

|

|

|

|

|||

|

Tolerance

|

±0.002 ~ ±0.005mm

|

|

|

|

|||

|

Surface Roughness

|

Min Ra 0.1~3.2

|

|

|

|

|||