NaN / 0

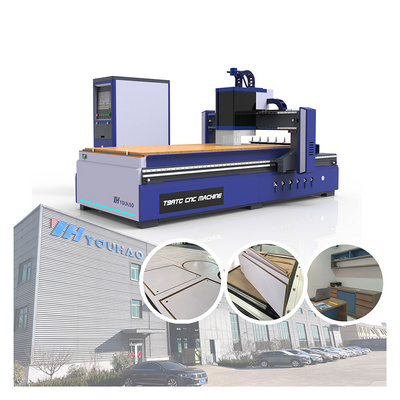

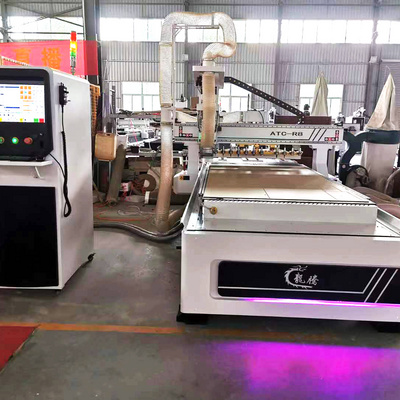

4x8 ft 3 Axis Wood CNC Router With ATC 1325 Automatic Tool Changer 3D CNC Router Engraver Machine for wood furniture

Get Latest Price

US$ 9000

≥1 Sets

US$ 8800

≥3 Sets

US$ 8500

≥5 Sets

Quick Details

Working Table Size(mm):

1300×2500

Machine Type:

CNC Router

Range of Spindle Speed(r.p.m):

6000 - 24000 rpm

Positioning Accuracy (mm):

0.01 mm

Product Details

Good Offer CNC ATC 1328 Linear 12 Tools Panel Cutting CNC ATC Fast Speed CNC ATC

|

Working operation |

1220*2440*200mm(suport 2800mm custom) |

|

Speed of spindle |

0-24000/min |

|

Spindle |

GDZ 9KW air cooling spindle |

|

Speed of tool changing |

Top speed |

|

Inverter |

11KW Hpmant |

|

Control system |

Taiwan MW system |

|

The transmission track |

Y axis original Taiwan Hiwin 25 linear rail |

|

Slider |

Y axis original Taiwan Hiwin 25 slider |

|

Cable |

High flexible shielded towing chain cable |

|

Limit |

Special for cutting machine |

|

Rack |

Original HICK |

|

Electric elements |

Original Zhengtai |

|

Reducer |

Motovario reducer |

|

Travel speed |

120000mm/min |

|

Operate speed |

35000mm/min |

|

Adsorb pump |

Water cycle 7.5kw |

|

Dust collector |

double bag 5.5kw |

|

Working Voltage |

AC380 v |

|

Machine body |

Heavy aging treatment welding bed(five face milling and drilling precision 0.02mm) |

|

Feed positioning |

Double-sided all-package positioning cylinder with aluminum strip |

|

Auto unloading |

Fully automatic tiled horizontal push blanking belt auxiliary aluminum bar stop function |

|

Dusting method |

Automatic spindle partitioning integrated dust removal and secondary dust removal. |

|

Machine appearance |

Third generation patent structure, independence controller cabinet |

|

Z axis module |

Z axis motor locking function, Z axis integrated motor screw support seat |

|

Gantry instruction |

Beam thick wall square pipe and steel belt welding synchronous bed processing technology, the column integral casting structure

|

Hot Searches