NaN / 0

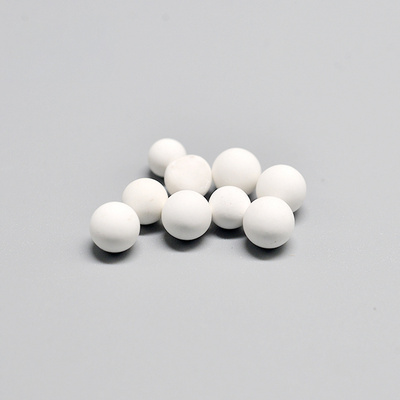

Factory Price Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

Get Latest Price

US$ 900

≥1 Pieces

Quick Details

Material:

Alumina Ceramic

Place of Origin:

Shandong, China

Model Number:

WD-CB92

Brand Name:

WD

Product Details

Product Description

Factory Price Zibo Grinding Media 92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

The microcrystalline wear-resistant 92% alumina ball produced by WellDone Environmaterials have good performance in grinding Feldspar, Clay etc, is a high-quality grinding medium made of selected high grade material, advanced molding technology and calcined in high temperature tunnel kiln. Possessed with high density, high hardness, low wear, good seismic stability and good corrosion resistance, the products are the most ideal medium for grinding glaze, blank and mineral powder processing, and are used as the grinding medium of ball mill in ceramics, cement, paint, refractory, inorganic mineral powder and other industries.

92% Alumina grinding ball is one ideal mill grinding media, it can keep the purity and improve the stability of the grinded materials especially the ceramic glaze. High alumina ceramic balls as grinding ball with high quality raw materials as well as the middle alumina ceramic balls are produced with the following technology: advanced spray drying technology, dry type full automatic isostatic pressure and high temperature roller kiln sintering technology.

Size of 92% Alumina Ceramic Balls:

1.Normal size: 3mm, 5mm, 6mm, 7mm, 8mm, 9mm, 10mm, 11mm, 12mm, 13mm, 14mm, 15mm, 16mm, 17mm, 18mm, 19mm, 20mm, 25mm, 30mm, 40mm, 50mm, 60mm. 70mm, 80mm, 90mm, 100mm These sizes our factory produce regular, many of them are in large stock.

2. We can provide the other sizes by customers’ requirements, just tell us what you need.

Specifications of 92% Alumina Ceramic Balls:

Other Al2O3 Content Alumina Ceramic Ball that we can produce:

Detailed Image

Application

92% Aluminum Oxide Al2O3 Alumina Ceramic Balls for Ball Mill

How to optimize the grinding process in Ball Mill for Alumina Ball:

1. In the situation of wet grinding

Usually,the total charges of the alumina balls in one ball mill should be not less than 55% of the total ball mill capacity.

Empirical formula of charged alumina ball quantity into ball mill:

M=3.14xR2xDxLx25%+1000

Remark M= charged alumina ball quantity(kg)

D=Alumina ball density(g/cm)

R=Radius of ball mill L=Ball Mill Length

Alumina grinding ball proportion:

For a bright new installed ball mill, the alumina balls proportion depends on the capacity of the ball mill and the fineness of the grinding raw materials

Alumina ball recharge quantity

Recharge quantity=Primary ball quantity*Ball wear loss*Grinding time

2. In the situation of dry grinding:

Dry grinding is widely used in mining, ceramics industries, we developed alumina balls performed well on dry grinding situation with much lower wear-loss, it helps solve the problem of materials contamination.

The proportion of the alumina ball for dry grinding depends on the hardness and fineness of the grinding raw material, generally speaking, CIP formed grinding ball used for dry grinding.

Wear-loss testing method of alumina ball:

This method is the Chinese domestic testing method, put alumina ball samples into polyurethane jar, testing the wear loss in the unit time.

Firstly, put 4kg alumina ball and 4L water into the grinding jar, put the jar into the testing machine, grinding 2h on the revolution of 80 r/min. Take out the samples dry them and get weight M1.

Secondly, put the above samples again into the jar, add 4L water, grinding 24h on the same revolution of 80 r/min.

Thirdly, take out the samples dry and get weight M2.

Fourthly, testing the average diameter of the samples, get average diameter D.

Fifthly, wearloss calculation:

EWT(%o )=KD M 1-M2 )M 1Empirical formula: EWT(%o)= (M1-M2)M1/24 /100*1000*D

Packing & Delivery

Our Company

Shandong Welldone Environmental New Materials Co.,Ltd.

WELLDONE Ceramics Plant was found in 1998, is a worldwide competitor of Alumina Balls, Bricks, Liners, Mosaics.. for Grinding, Lining, Polishing, Filling... We have more than 20 years of experience in manufacturing high quality alumina grinding balls, Bricks, Liners, Mosaics..and many other environmental materials, products had been exported to North America, Europe, Middle East and South-east Asia. We had been listed as CHINA TOP 10 manufacturer, annual production capacity for alumina balls 65,000 metric tons.

To offer GREEN CHEMICAL and ENVIRONMENTAL FRIENDLY CHEMICAL is our mission, 23 professional engineers are focusing on environmental production technical improvement, 2 teams focusing on offering staff safety guarantee. And we had helped 300+ companies of environmental grinding.

We look forward to establishing long term cooperation with company from all over the world.

FAQ

1.What types of Alumina Ceramic Balls can you produce?

A:Our plant could produce 68%, 75%, 80%, 92% 99% Al2O3 Alumina Ceramic Balls, could meet your different need.

2. What main sizes do you have in stock?

A: For 92% Alumina Ceramic Balls, many sizes are in mass production, always in stock.

3.What is your Minimum Order Quantity?

A: 1 MT. The price can be discount for the large order.

4.Can you provide free samples?

A:Free samples always can be offered for your checking, just contact us to get it.

5.What about the package?

A:cartons or pp bags, also we can pack as your request.

Hot Searches