NaN / 0

Small Hollow Fiber Nitrogen Membrane for Gas Separation

Get Latest Price

US$ 400

≥1 Pieces

US$ 399

≥5 Pieces

Quick Details

Place of Origin:

-

Brand Name:

-

Production Rate:

100%

Voltage:

-

Product Details

Small Hollow Fiber Nitrogen Membrane for Gas Separation

Product Description

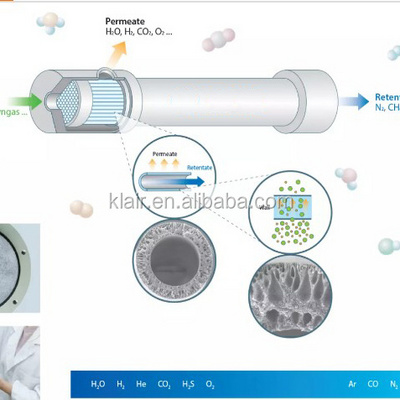

Gas separation membranes are very fine hollow fibers through which different mixtures of gases are fed.

As the gases travel through the tubes, a process called selective permeation allows us to separate gases.

At a closer look, gas separation membrane, the wall of each of these micro-thin hollow fibers, is an asymmetric filter made of various types of polymer. As different gases travel through the fiber, they come into contact with the membrane and permeate through it.

The permeation rate of each gas is determined by its solubility in the membrane material and its diffusion rate. Gases with higher solubility and smaller molecules (fast gases) can pass through the membrane faster than other less soluble gases with generally larger molecules (slow gases).

Gases which permeate faster and more are collected outside of the hollow fiber as permeates while gases which do not permeate so well and stay inside of the fiber until they reach the other end are separated out as retentates. Depending on the properties of the desired gas, either or both of permeates and retentates can be used.

Membrane Technology - Benefits

-

Simple and Reliable Design

· No auxiliary media (water, solvents, etc.) required

· Simple modular set-up without break-in period

· Compact system with low space requirements -

Flexible Application

· Modular design allows easy expansion

· Flexible positioning and integration with the main system

· Easy to adjust purity

-

Economic Solution

· Low installation costs

· Low operational costs

· Low maintenance requirements: time and costs saved -

Improved Safety

· No risks associated with handling gas cylinders

· No chemicals required -

Environmental Benefits

· Separation at room temperature: low energy consumption

· No phase change

· No environmental emissions (no waste water or absorbent) -

P ls kindly send it with below technical information , that's better for us quickly feedback your inquire:

1) F low rate: _____Nm3/h

2) Working pressure: _____Bar

3) Oxygen gas or Nitrogen gas: _____

4) Pure : ______

5) Temperature:______

6) Application: _______

Explore More Products

Hot Searches