NaN / 0

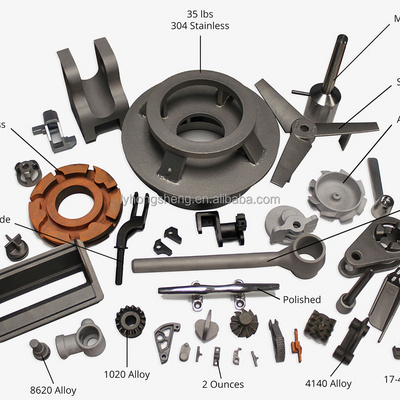

precision casting Stainless Steel casting case part,investment casting SS304 housing part,SS316 lost wax casting cover shell

Get Latest Price

US$ 5

≥1 Pieces

Quick Details

Place of Origin:

Jiangsu, China

Brand Name:

paipu

Model Number:

investment casting

Product name:

investment casting parts

Product Details

Product Images

We can customize according to your drawings or samples.

We provide one-stop service.

Products Description

1,

Description

|

Technology

|

Investment Casting

|

|

|

|

|||

|

Material

|

Stainless steel

|

|

|

|

|||

|

Surface Treatment

|

Polishing,Powder Coating,Paiting,Sandblast,Shot blast,Electroplating

|

|

|

|

|||

|

Processes

|

1, Sign Drawing (General clients provide the drawing or samples)

2, Make the Mold

3, Casting 4, Precision Machining (Burring, Lathe, Milling, etc) 5, Surface treatment. 6, Inspection and Packing |

|

|

|

|||

|

Drawing file:

|

IGS, STEP, PDF ,DXF

|

|

|

|

|||

2, Technical Support

Paipu Group is professional at independent development and design. Our engineers are skilled at

AUTO CAD, PRO ENGINEER, SOLID WORKS

and

other 2D & 3D softwares

. We are able to design, develop,produce and deliver your PO according to your drawings, samples or just an idea. Dural control of standard products and OEM products.

3, Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)