NaN / 0

customized snail slime machine emulsifier liquid mixer food machine

Get Latest Price

US$ 2699

≥1 Sets

US$ 2599

≥3 Sets

US$ 2499

≥5 Sets

Quick Details

Barrel Volume (L):

400

Max. Loading Volume (L):

400 L

Range of Spindle Speed(r.p.m):

10 - 60 r.p.m

Max. Loading Capacity:

400L

Product Details

Product Description

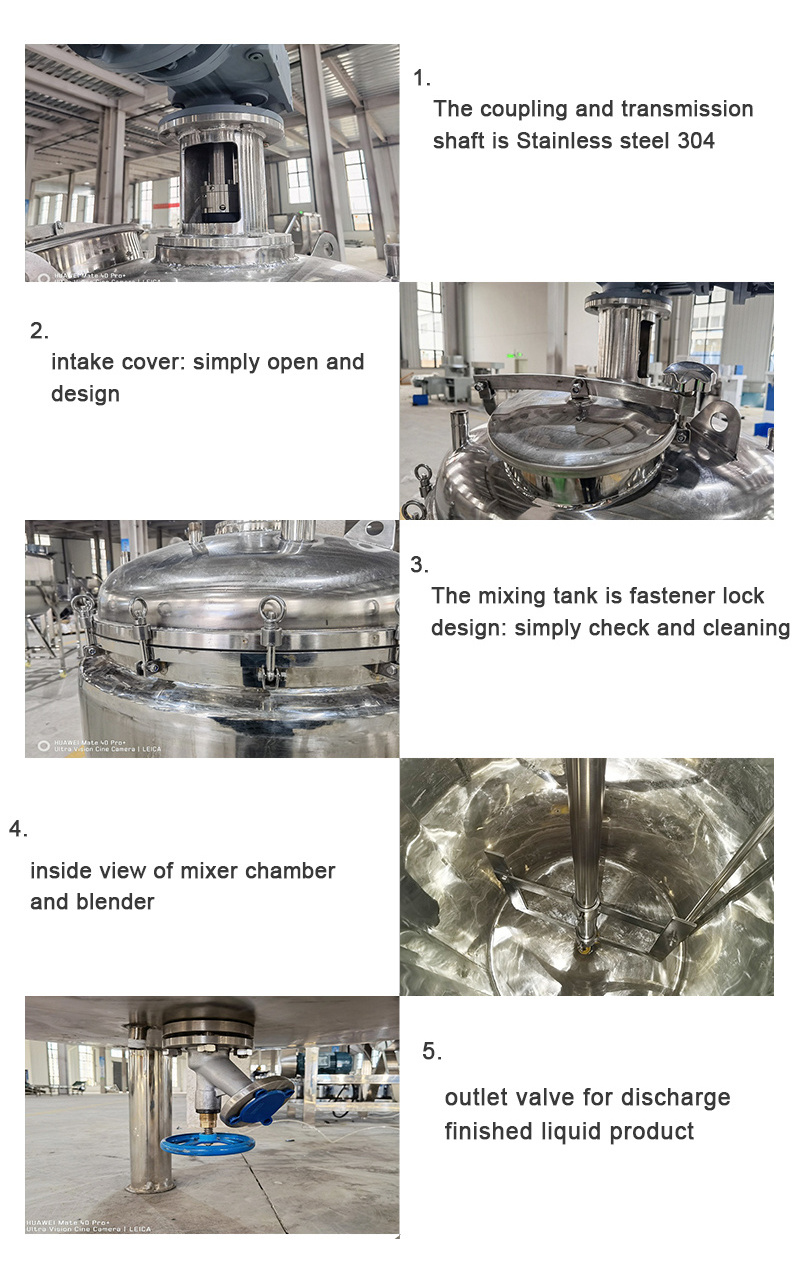

100L-500L stainless steel jacketed heated electric chemical agitation tank

This is a liquid mix tank, also known as aqueous phase tank, is widely used in paint, building materials, chemical, pigment, resin, food, scientific research and other industries. The equipment can be made of carbon steel, stainless steel and other materials according to different process requirements and production needs of users, and can be equipped with heating and cooling devices. Stirring tank is a kind of container which can stir, mix, blend and homogenise materials. According to different production process requirements, different structures and configurations can be designed to meet the standardised and user-friendly production.

There are two kinds of heating methods: jacketed electric heating and coil heating. Reasonable structure, advanced technology, durability, simple operation, easy to use, is the ideal chemical device with low investment, fast production and high benefit. It can realise charging control, discharging control, mixing control and manual and automatic control during mixing.

Features:

1,Reliable sealing, stable sealing state in long-term operation, the leakage is very small, the leakage is only about 1% of the packing seal.

2, long service life, in the oil, water media generally up to 1-2 years or longer, in the chemical medium generally can work more than half a year.

3, shaft or shaft sleeve basically no wear.

4, long maintenance cycle, end face wear can be automatically compensated, generally do not need regular maintenance.

5,Good vibration resistance, insensitive to the vibration of the rotating shaft, deflection and shaft deflection of the sealing cavity.

6, a wide range of applications, can be used for high temperature, low temperature, high pressure, different rotational frequency, as well as a variety of corrosive media and abrasive media containing seals.

Parameters:

Our Company