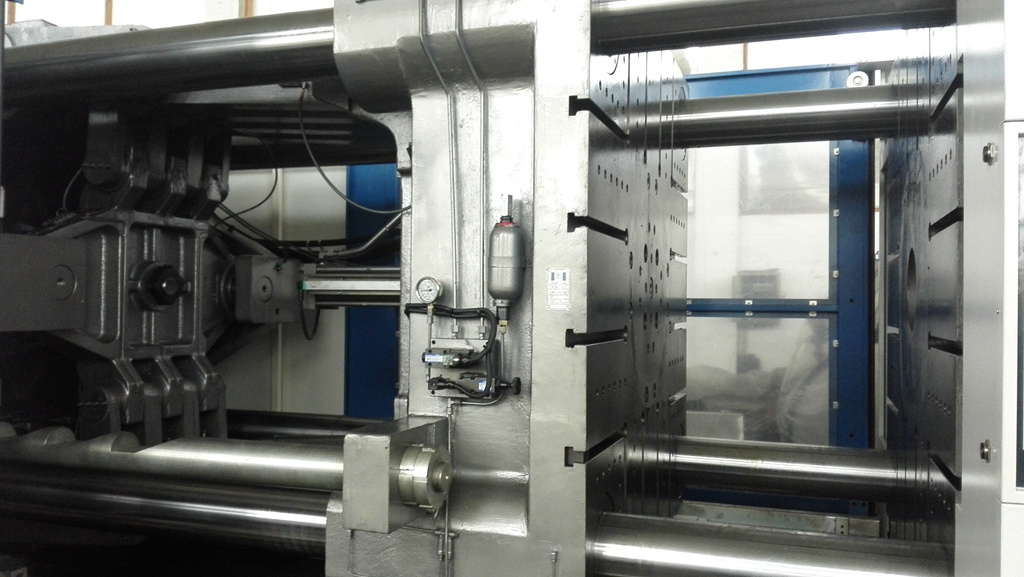

1) Precision hydraulic synchronous template adjusting system.

2) Optimal design of high-strength, precision clamping unit.

3) Large screen, high precision machine computer system.

4) Optimized electric system.

5) Balanced type of double whole transfer oil cylinder.

6) Large torque oil motor.

7) High abrasion-resistant alloy sliding block.

8) The integrate type of detachable oil tank, magnetic filter and bypass strainer.

9) Reasonable and high efficient lubrication system.

10) Modularized energy conservation, high response oil-way system.