NaN / 0

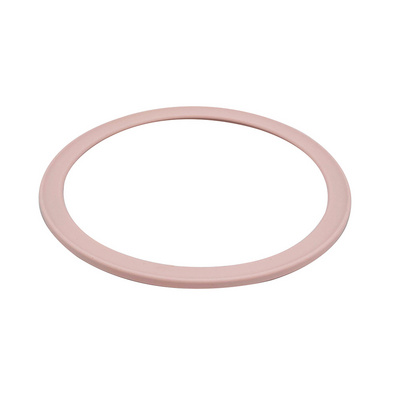

food grade liquid silicone gasket o ring sealing seals

Get Latest Price

US$ 0.2

≥10 Pieces

US$ 0.1

≥5000 Pieces

US$ 0.01

≥10000 Pieces

Quick Details

Size:

custom

Place of Origin:

Guangdong, China

Brand Name:

BT Rubber

Model Number:

IMG_4199

Product Details

food grade liquid silicone gasket o ring sealing seals

Foshan Better Rubber Products Co.,Ltd. is a professional manufacturer of silicone rubber. We produce various silicone rubber products and have passed ISO9001, and ISO14001certification. The production process fully complies with environmental regulations.Customized rubber parts are our advantage. The wide application fields of our rubber products, including household, automotive, beauty,aerospace, machinery, petrochemical, medical, food, electronic, national defense, military industry equipment, etc.

| Product Description |

| Material | NBR, SBR, HNBR, EPDM, FKM,FPM, MVQ, FMVQ,FFKM CR, NR, TPR,TPU,SILICONE, etc. |

| according to the customers' requirements | |

| Dimension | Standard sizes, also can be customized |

| Hardness | 20-90 Shore A or IRHD |

| Certification | Rohs,ISO9001,IOS14001 |

| RoHs | RoHs directive compliant green products |

| Rapid Development line | A. From drawing, new tool design to mold support and samples. |

| B. Prototype mold, usually in 7 days; | |

| C. Mass production mold, usually in 1~2 weeks. | |

| Advantages | Professional sales-team and technology-team, molding center, high-tech testing machine and so on |

| Mould | The quantity reaches 5000, there is no mold fee. Quantity reaches some amount, mold fee can be refund. |

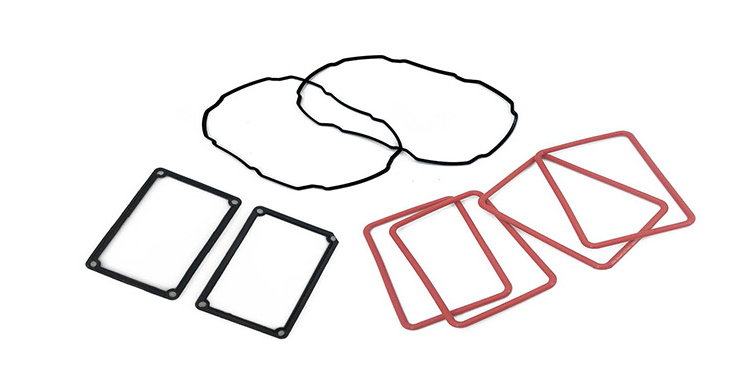

Our company can be provided O-ring,gasket,stopper,strip,bellow,cap,washer,valve,cord,cover,plug and lots of other rubber products .

Not only standard rubber products but also various rubber shaped parts can be provided by us.

Various of materials, including:SILICONE, NBR, HNBR, EPDM, FKM, FFKM, IIR, PTFE, CR and so on.

We can also; Select & develop material;

Recommend sizes & Design;

ODM/OEM Service;

Custom Design.

We can produce any size and shape according to your drawing, some successful cases show below:

| Our service |

Pre-sales Solving problems and proposing sealing ways. Our engineers could offer design & selection support, and free sample could be provided for testing.

Middle-sales To respect customers, service actively. Satisfying customers require-ments as our aim. Controlling product quality & delivery time strictly.

After-sales Tracking customers and replying questions positively. Answering problems patiently. If quality could not satisfy your request, return / exchange policy is available

| Our Advantage |

| Our | Others | |

| R&D | 5000 product development experiences | does not necessarily have a R&D team |

| Material | internationally manufactures | unknown admixture |

| Precision | 0.3mm minimun,Fewer burrs | uneven |

| Dissimilar material bonding | dozens of multi-materials products | specific species |

| Durability | buttons can be pressed up to one million times | high replacement rate |

| Defect-free rate | up to 99.7% | <99.5% |

| Moq | 100pcs | >100pcs |

| Risk control | mold design | NO |

| About US |

| Certificate |

| FAQ |

1.

What's the payment term?

We accept T/T 30% deposit and 70% balance against copy of B/L or L/C at sight, West Union,VISA,Paypal is also accepted.

2. What is the normal lead time for product orders?

Average lead times for prototype / first article are 1-2 weeks, if tooling is involved, lead time for production tooling is 10 days, average production time after sample approval is 2-3 weeks.

3. What is your standard packing?

All the goods will be packed by carton box and loaded with pallets. Special packing method can be accepted when needed.

4. Could you please tell us the month capacity of your products ?

It depends on which model, we produce more than 2500 tons rubber materials per month.

5. what kind of certificates you have ?

We hav

e

ISO9001

,

ISO14001

and Rohs

certified

6

.

How to check the quality of the bulk order?

We provide preproduction samples before mass production for all customers if needed.

7

.

How to select the raw compound for my application?

With years of experience working with a variety of material, we can help select the material that will best suit your needs while keeping material costs in mind.

8.

Can you supply different color materials?

Yes, we can produce custom molded rubber and silicone rubber products in different colors, the color code will be required in case of an order.

9.

What materials are available to produce from your side?

NBR, EPDM, SILICONE, FKM, NEOPRENE(CR), NR, IIR, SBR, ACM, AEM, Fluorosilicone(FVMQ), FFKM, Liquid Silicone, Sponge, etc.