NaN / 0

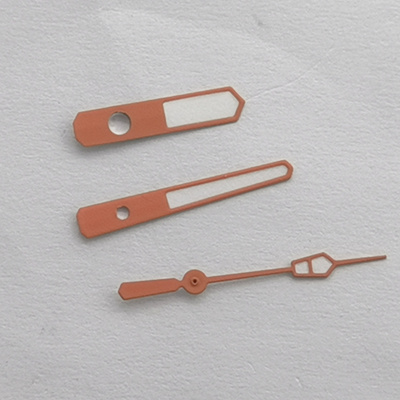

High Precision Oem Cnc Small Automatic Movement Watch Mechanical Parts

Get Latest Price

US$ 0.9

≥1 Pieces

US$ 0.8

≥100 Pieces

US$ 0.7

≥1000 Pieces

Quick Details

CNC Machining or Not:

Cnc Machining

Material Capabilities:

Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, Stainless steel, Steel Alloys, PPS

Place of Origin:

Guangdong, China

Model Number:

Plastic Parts-2

Product Details

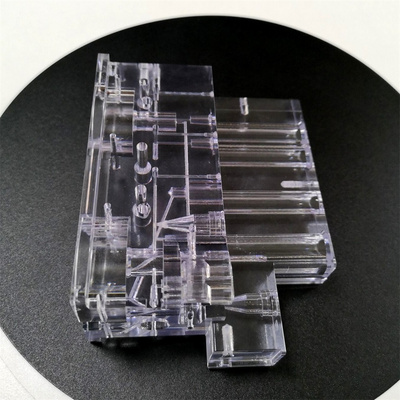

Plastic Medical Parts 3D Printing Machine Parts CNC Machining Service

|

Company Name:

|

Shenzhen HTX Technology Co., Ltd.

|

|

Total Building:

|

12000 Square Meters

|

|

Experience:

|

23 Years (Since 1998)

|

|

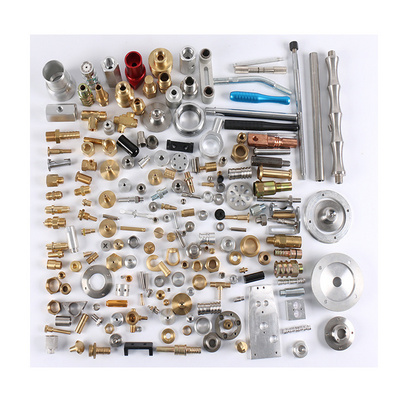

Equipments:

|

CNC turning, Auto-Lathes, CNC Machining Center, Stamping Machines, CNC spring machining, cnc cuting machine, welding machine,Hydraulic press, stone polishing machine, auto-milling machine, Driling Machines, Heading Machines, Slotting Machines,Tapping Machines, Chamfering Machines, Grinder Machines,Polishing Machine and so on

|

|

Testing Equipments:

|

3D measuring machine, Height Gage, Coordinate Measuring Machine, Hardness Tester, Video Measuring Machine, Roughness Tester, Torsion Tester, Salt Spray Tester,Slide caliper, Micrometer.

|

|

Material:

|

Titanium Alloy, Brass, Bronze, Copper, Aluminum, Mild Steel, Stainless Steel, A366, Alloy, Carbon steel, ABS, PC, PEEK, PPS, PPS GF40, PPS GF30, POM, PET and so on.

|

|

Surface Treatment:

|

Zinc Plating, Nickel Plating,Chrome Plating, Passivation, Hardening, Anodizing, Black Oxide Coating,Degreasing, Brushing, Electronic Polishing, Powder Coating, Gold plating, Stone Polishing, PVD Coating

|

|

Certification:

|

GB / T19001-2016 / ISO9001:2015 CertificateNo.30418Q00468R0S, SG S Factory Certificate

|

FAQ

What’s the normal surface treatment?

Colorful Anodizing,Passivation, Chrome, Electroplating, Polishing, Powder Coating, Blacken, Hardening, Painting and many other treatment of the parts.

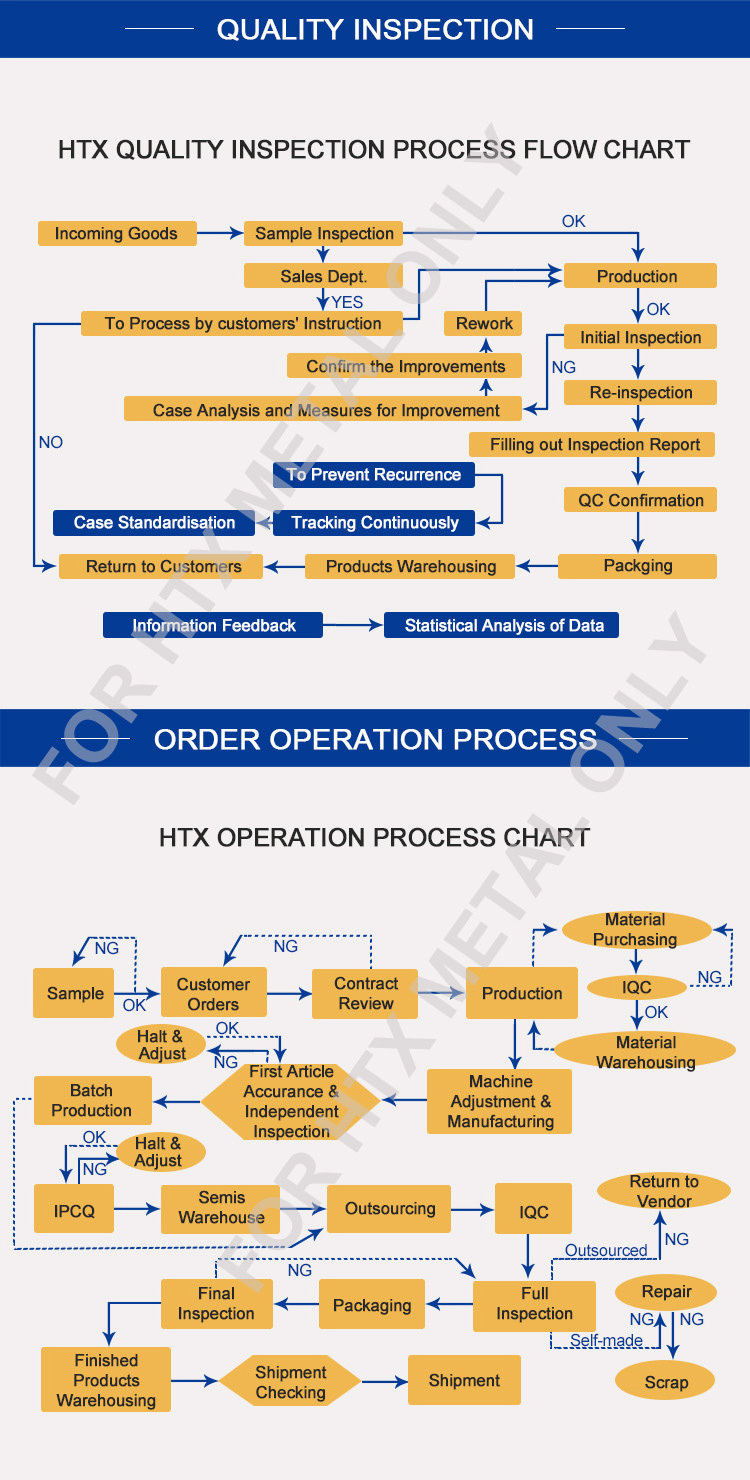

How do you ensure the quality?

100% inspection. We use the Height Gage, Coordinate Measuring Machine, Hardness Tester, Video Measuring Machine, Roughness Tester, Torsion Tester, Salt Spray Tester and so on to test our goods.

Can you issue the drawing?

Yes, we can issue the CAD drawing and 3D drawing as per customer’s request or samples.

What’s your request time?

1 week for samples, and 10-25 workdays for bulk production

What’s your packing method?

PP bag, carton and Pallet, or as per customer’s request.

What’s your MOQ?

1pcs, more quantity, more cheaper price.

Why Choose HTX

1. 21st years in metal machining industrial

2. Different machining equipments to meet different metal machining request.

3. Factory price with high quality ISO standard process.

4. Advanced equipment machining to meet high tolerance(±0.002) product request

5. Prompt lead time request.

6. Prompt feedback, all enquiry will be replied within 24 hours.

7. Great reputation in machining industry, the goods have been exported to American, Japanese, European, Australia, Middle East, Africa and so on.

8. Low price, small profit by quick turnover is our business principle.

9. 100% quality insepction to ensure the quality for each unit.

10. R & D team to design the goods according customer’s request.