NaN / 0

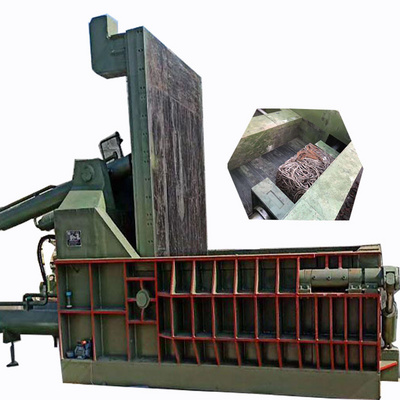

Baling press for scrap metal/ Scrap Baler/ Scrap metal compactor press machine

Get Latest Price

US$ 9800

≥1 Sets

US$ 9500

≥3 Sets

US$ 9000

≥10 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

ZHENGDIAN

Marketing Type:

Hot sale 2022

Model Number:

Y81-63/Y81-100/Y81-125

Product Details

Product Description

Scrap Metal Press Machine

Metal baler machines are mainly used in recycling and processing industries and metal smelting industries. Various metal scraps,steel shavings, scrap steel, scrap iron, scrap copper, scrap aluminum, aluminum shavings, disassembled car shells, waste oil barrels and other metal raw materials can be squeezed into various shapes of qualified furnace materials such as cuboids and cylinders. . It is convenient for storage, transportation and recycling.

Application

The equipment can put cans, paint buckets, iron cans, scrap iron, scrap steel, iron sheets, bicycles, color steel tiles, light and thin materials, pig iron, thin iron, dew cans, red bull cans, scrap aluminum, scrap copper, iron drums, automobiles Shells, car frames, metal scraps, aluminum alloys and other scrap metals are pressed and formed at one time.

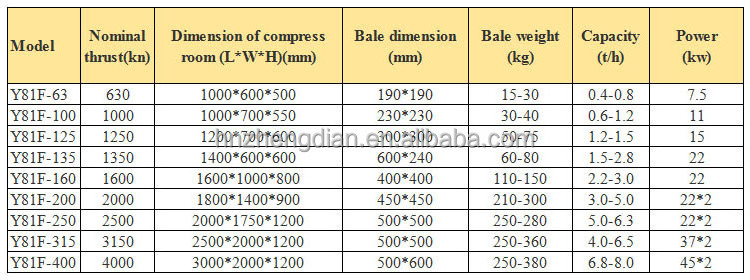

Specification

Features

1 The hydraulic system applies an integrated valve block and the product is stable and reliable in technical performance.

2 The discharging types fall into turning over, push out ,forward out and manual lifting.

3 It is unnecessary to fix foot screw and a diesel engine can be used in case of power supply unavailability.

4. Smooth operation; computer control, high degree of automation, low failure rate, easy maintenance and so on.

5. High strength, good stability.

6. The hydraulic station system uses a unique cooling system, so that the oil temperature is not easy to rise.

2 The discharging types fall into turning over, push out ,forward out and manual lifting.

3 It is unnecessary to fix foot screw and a diesel engine can be used in case of power supply unavailability.

4. Smooth operation; computer control, high degree of automation, low failure rate, easy maintenance and so on.

5. High strength, good stability.

6. The hydraulic station system uses a unique cooling system, so that the oil temperature is not easy to rise.

Details Images

Contact Us

Hot Searches