NaN / 0

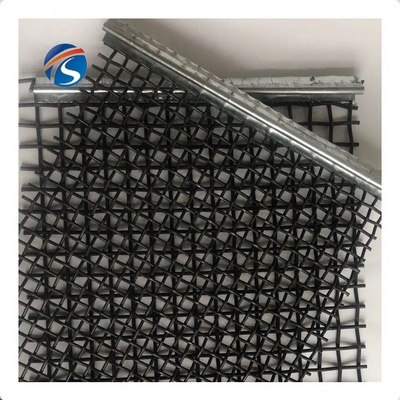

65Mn Heavy Duty Spring Steel Wire Mesh for Vibrating Screen

Get Latest Price

US$ 8.5

≥50 Pieces

US$ 7

≥200 Pieces

Quick Details

Material:

65Mn high carbon steel wire

Type:

Hooked Screen,Plain Screen,Crimped Screen,Locked screen

Application:

Screen

Place of Origin:

Hebei, China

Product Details

Hot Sell

Product Description

Wire diameter: 0.71-12.5mm

Hole size: 1-100mm or as you requested

Width: 0.5-1.5m

Length: 1-30m or as you requested

Material: High tensile spring steel, manganese steel, high carbon and medium carbon steel wire, black wire, and stainless steel wire.

Surface treatment: Galvanized before weave and galvanized after weave, painted

Hole type: Square mesh, rectangular mesh

Weaving type: Double crimped, intermediate, crimped, flat top crimped, lock crimped.

|

Available Steel Material |

||||

|

No |

Grade |

Chemical Composition |

||

|

C |

Si |

Mn |

||

|

1 |

45 |

0.42-0.50 |

0.17-0.37 |

0.50-0.80 |

|

2 |

50 |

0.47-0.55 |

||

|

3 |

55 |

0.52-0.65 |

||

|

4 |

60 |

0.57-0.65 |

||

|

5 |

65 |

0.62-0.70 |

||

|

6 |

70 |

0.67-0.75 |

||

|

7 |

65Mn |

0.62-0.70 |

0.90-1.20 |

|

|

8 |

72A |

0.70-0.75 |

0.15-0.35 |

0.30-0.60 |

Features:

- Professional production equipment, many machines and equipment, and the product mesh is relatively accurate

- High endurance and high mechanical efficiency

- The tablet is proper, with good reticulation

- Rich experience, according to different methods, increase the production method of products

- The edging can be customized according to customer requirements, such as shape, size, material, weldable, etc.

Product Overviews

Features

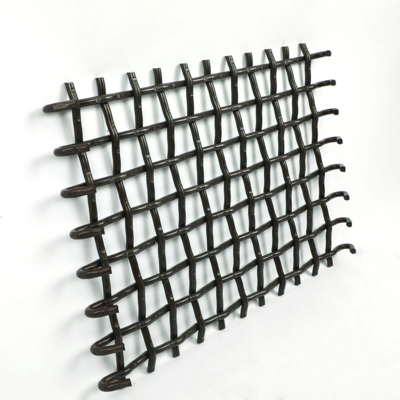

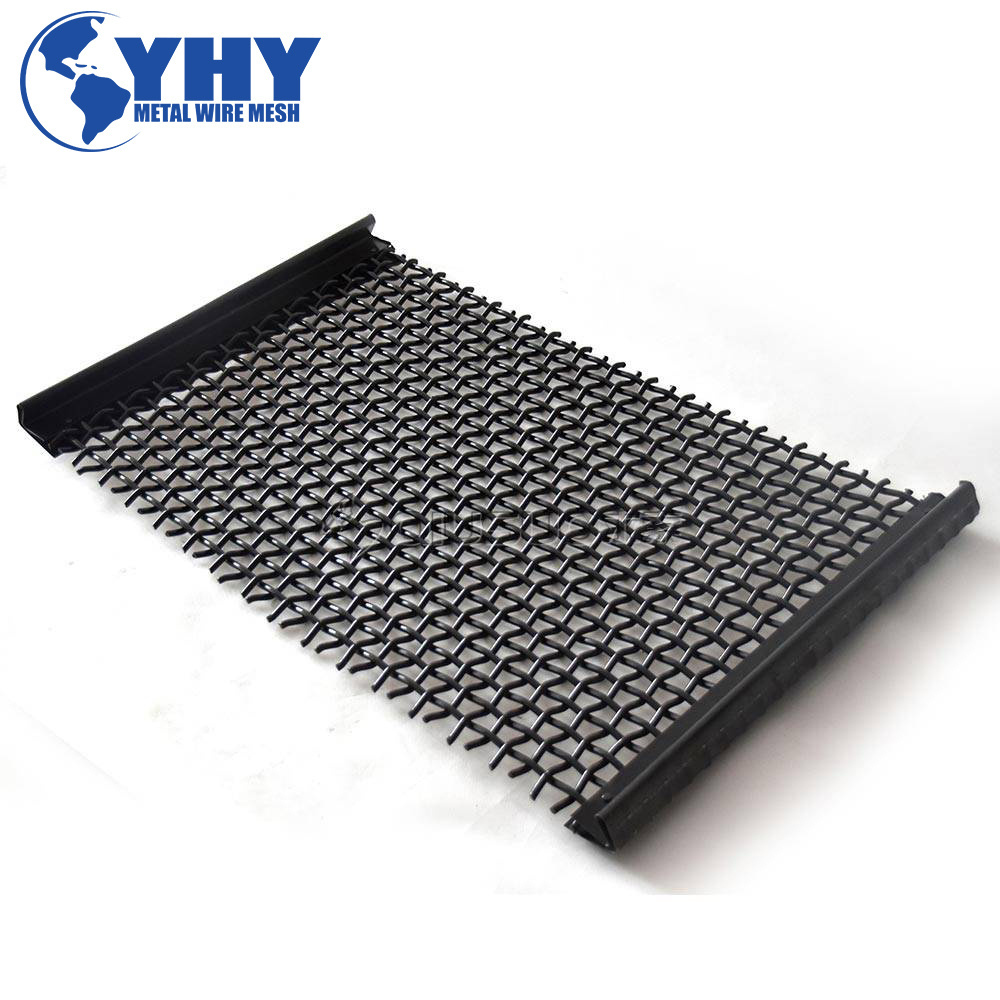

Double Weave

Also referred to as "Over and Under" this weave is commonly used for screening operations in smaller openings. Used for medium to heavy wire in relation to screen opening size.

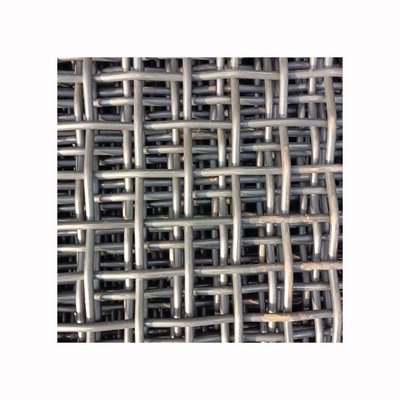

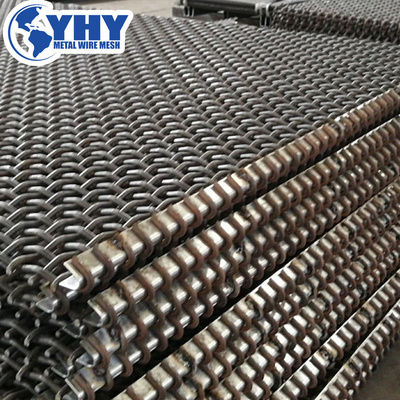

Scalping Weave

This weave is also referred to as "Lock-Crimp" due to the deep crimps which lock the wires in place. For light to medium wire in relation to screen opening size.

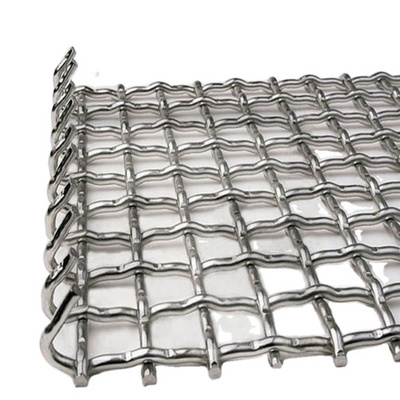

Double Lock Crimp

Single shoot oblong openings solve minor blinding problems for better flow.

Flat-Top

Improves material flow with a much smoother, flatter surface than other weaves. Lock weave provides a longer wear life and maintains accurate openings.

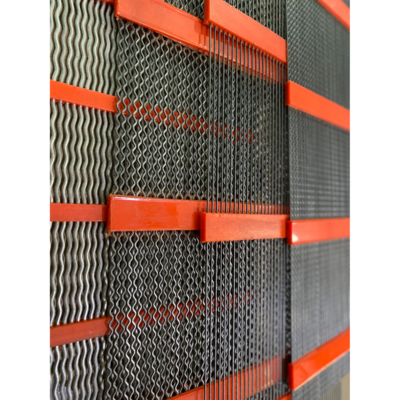

Intermediate Crimp

When open area is important. Extra crimps between the intersections provide a more rigid weave and provide locking and tightness for light wires in relation to the large openings.