NaN / 0

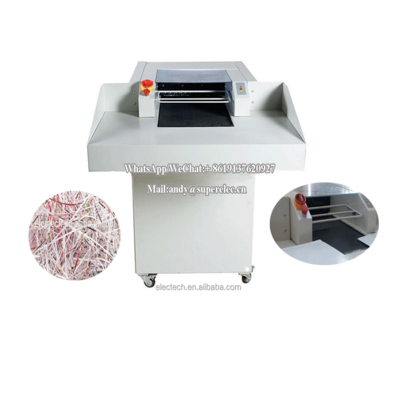

Foam shredder machine/carton shredder machine/heavy duty paper shredder

Get Latest Price

US$ 15000

≥1 Sets

Quick Details

Place of Origin:

China

Motor:

Siemens

Siemens:

NSK or SKF

Application:

foam shredder machine

Product Details

Foam shredder machine/carton shredder machine/heavy duty paper shredder

Product Description

Product Overview:

LDT Double-shaft Shredder adopt microcomputer (PC) automatic control system, under the open mode, you can start, stop, reverse and overload automatic inversion control function. Low speed, high torque, low noise characteristics. Bearing adopts the open type, easy to replace blade. Suitable for tear big volume, thick and difficult to break materials. Double-shaft shredders are widely used by domestic and foreign users in power plants, recycling processing, metallurgy, Forestry wood processing, garbage recycling, biomass energy and other industries, it is also known as multi-functional shredders, universal shredders.

Technical Parameter:

| Mondel |

Blade Specifications (mm) |

Blade Quantity (piece) |

Reducer (set) |

Motor Power (kw) |

Spindle Speeds (r/min) |

Dimensions (mm) |

| LDT600 | Φ250*10 | 48 | 400*2 | 15*2 | 18-25 | 1450*870*2200 |

| LDT800 | Φ250*20 | 32 | 400*2 | 30*2 | 18-25 | 2150*870*2200 |

| LDT1000 | Φ350*30 | 28 | 650*2 | 37*2 | 18-25 | 3400*1250*2200 |

| LDT1200 | Φ350*30 | 38 | 650*2 | 55*2 | 18-25 | 4150*1250*2200 |

| LDT1500 | Φ400*40 | 36 | 750*2 | 75*2 | 18-25 | 4150*1250*2200 |

| LDT2000 | Φ530*50 | 38 | 850*2 | 90*2 | 18-25 | 5250*1780*2200 |

Working Principle:

The Double-shaft shredder consists of rack, motor, reducer, crusher, PLC control system and so on. When operated, the main motor is directly rotated by the reducer to rotate the two main rollers. The roller has a spiral of high hardness alloy gear running,

In the the strong shear of two groups of gear, broken out . If the material difficult to be broken,the two main rolls can be reversed automatically under the automatic control system of PLC, the two main rolls can be turned back and forward repeatedly until the material is broken and discharged.

Advantages of LUODATE Double-shaft shredder

Good main parts: thick gear tooth, high crushing power, the knife roll are made of forged alloy steel, consolidation and long service life.

Hard machine body: thick tectonic plate , high resistance torque, very strong.

Easy to operate: The microcomputer (PC) is used to control the active operation of starting, stopping, turning and overloading, with superior performance.

No pollution: low speed , low noise pollution, less dust, environmental compliance.

High efficiency: The machine is easy to adjust, the maintenance cost is low, economical and practical.

Use wide: the thickness of the knife roll and the number of gear teeth can be replaced according to different materials.

New concept: the concept of screening,the unqualified materials can be shredded twice time.

Multi requirements: The gear tooth number and thickness can be changed freely to meet the user's requirement of material size.

Application

1. For the material properties, the flexibility to choose the equipment knife roller will enhance the effect of crushing.

2. Different knife rooler can be used for different material requirements.

3. The correct choice of knife roller can greatly improve the design performance and production efficiency.