NaN / 0

25 Tons Per Day Complete Rice Milling Machinery Parboiled Rice Mill Price In Nigeria

Get Latest Price

US$ 9000

≥1 Sets

US$ 8200

≥6 Sets

Quick Details

Place of Origin:

Henan, China

Brand Name:

Hongjia

Voltage:

customized according to customer's needs

Power:

28kw

Product Details

25 Tons Per Day Complete Rice Milling Machinery Parboiled Rice Mill Price In Nigeria

Products Description

Zhengzhou Hongjia Grain Machinery Co.,Ltd, China professional full automatic rice milling machine, parboiled rice mill plant,

complete

rice mill machine manufacturer, we can supply from 15-500 Tons capacity complete rice mill plant to meet different needs.

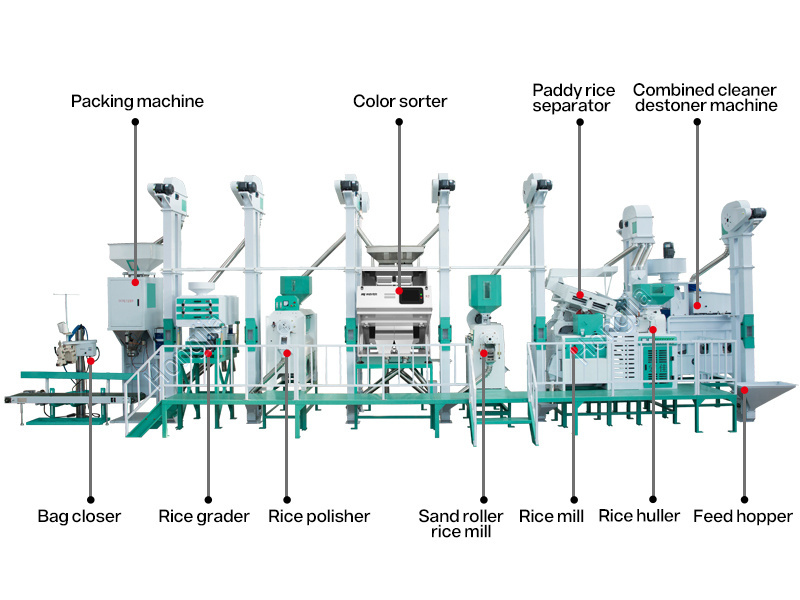

The complete configuration is whole line include paddy cleaning de-stoning, rice hulling, paddy rice separating, rice whitening, rice polishing, rice color sorter, rice grader and packing machine.

Flow chart of parboiled rice mill line:

The 25T/D complete rice mill machinery can process paddy into national standard rice just in one process at the following flow chart:

Raw Material Pre-cleaing

→Soaking

→Boiling

→Drying

→

Vibrated cleaner & Destoner → Rice Hulling→Paddy Rice Separator → Rice Mill →Rice Polisher → Rice Grader→ Rice Color Sorter → Packing, Then the rice can be on market for sale.

Functioning and steps in rice milling processes:

1. Hopper: feeding raw paddy material to the rice mill machine

2. Combined paddy cleaner & de-stoner: other light impurities such as dust and debris, block, the stone should be removed as much as possible to reach a better cleaning effect.

3. Rice husker: remove husk from paddy.

4. Rice separator: it is mainly used for separating brown rice from paddy making use of their differences in specific gravity and friction coefficient in three parts: paddy, brown rice, and a mix of both.

5. Rice mill machine: the rice whitening machine is developed for rice whitening, which is an advanced technology of the world rice mill whitener at present to make rice temperature down, bran content less, and broken increment lower.

6. Rice polisher: polishes the rice surface by spraying water, which facilities the formation of a smooth gelatinous layer that prolongs the preservation time. Extended polishing chamber to produce high-quality rice.

7. Rice grading machine: the rice grader can sieve milled rice efficiently and accurately into several classes: head rice, large broken, medium broken, small broken, etc.

8. Rice color sorter: the rice color sorting machine is used to sort bad, milky, Chalky, Paddy, foreign materials out. The CCD signal while blanking is been tested. If it is found that there are unqualified rice or impurities in the materials, the ejector will blow the defective goods in the hopper.

9. Rice packing machine: this rationed automatic weighing packing machine consists of a material box, a packing scale, a sewing machine, and a conveyor belt. It can cooperate work with all the model's rice mill production line, and also for the packing bags capacity can choose 1-50 kg per bag for your needs.

3. Rice husker: remove husk from paddy.

4. Rice separator: it is mainly used for separating brown rice from paddy making use of their differences in specific gravity and friction coefficient in three parts: paddy, brown rice, and a mix of both.

5. Rice mill machine: the rice whitening machine is developed for rice whitening, which is an advanced technology of the world rice mill whitener at present to make rice temperature down, bran content less, and broken increment lower.

6. Rice polisher: polishes the rice surface by spraying water, which facilities the formation of a smooth gelatinous layer that prolongs the preservation time. Extended polishing chamber to produce high-quality rice.

7. Rice grading machine: the rice grader can sieve milled rice efficiently and accurately into several classes: head rice, large broken, medium broken, small broken, etc.

8. Rice color sorter: the rice color sorting machine is used to sort bad, milky, Chalky, Paddy, foreign materials out. The CCD signal while blanking is been tested. If it is found that there are unqualified rice or impurities in the materials, the ejector will blow the defective goods in the hopper.

9. Rice packing machine: this rationed automatic weighing packing machine consists of a material box, a packing scale, a sewing machine, and a conveyor belt. It can cooperate work with all the model's rice mill production line, and also for the packing bags capacity can choose 1-50 kg per bag for your needs.

Product Paramenters

|

No.

|

Name

|

Model

|

Quantity

(Set)

|

Single Power

(kW)

|

|

1

|

Vibrate cleaner and destoner

|

ZQS-60

|

1

|

1.1+2.2

|

|

2

|

8 Inch rice huller

|

LG15A

|

1

|

5.5+1.1

|

|

3

|

Paddy separator

|

MGCZ80*5

|

1

|

0.75

|

|

4

|

Rice mill

|

MNMS18

|

1

|

18.5

|

|

5

|

Rice mill

|

MNMS15

|

1

|

15

|

|

6

|

Rice polisher

|

MPG12.8

|

1

|

22+7.5

|

|

7

|

Rice grader

|

MMJP63*3

|

1

|

0.75

|

|

8

|

Rice color sorter

|

SX-80

|

1

|

1.1

|

|

9

|

Packing machine

|

DCS-50A

|

1

|

0.75

|

|

10

|

Elevators

|

TDTG18/08

|

7

|

0.75*7

|

|

11

|

Electric control cabinet

|

|

1

|

|

|

12

|

Pipeline

|

|

1

|

|

|

13

|

Hopper and accessory

|

|

1

|

|

Main Features

Our advantages of complete rice milling machinery

1. Twice rice mill machine has lower pressure in the polishing chamber, lower break rice rate;

2. Water polishers, color sorters, and rice graders' other systems will bring you high precision rice;

3. It is the ideal machine for milling various rice, such as long-shaped rice, polished round-grained rice, sticky rice, Thailand jasmine rice, basmati rice, etc; also can press parboiled paddy;

4. Having a high automation degree and realizing continuous automatic operation from paddy feeding to finished rice packing;

5. Rice milling speed is fast, the complete set of equipment has a daily output of about 25 tons;

6. The structure is neat and beautiful, and the energy consumption is low. The operation and maintenance are convenient, and the disassembly and assembly of all equipment are very convenient;

7. The rice milling part of the equipment adopts negative pressure rice milling technology, which has low rice temperature, no chaff, and fewer broken rice rate;

8. Our processing technology: Optical fiber cutting, CNC bending, CNC machine tools, spraying process, high-position spray baking, etc;

9. According to the requirement of the crafting flow, “one” arrangement, the main operations are concentrated in the middle, convenient to operate;

10. High-strength vibration-absorbing bearing configuration, the machine body moves smoothly, is firm and reliable, has low vibration, low noise, and low dust;

2. Water polishers, color sorters, and rice graders' other systems will bring you high precision rice;

3. It is the ideal machine for milling various rice, such as long-shaped rice, polished round-grained rice, sticky rice, Thailand jasmine rice, basmati rice, etc; also can press parboiled paddy;

4. Having a high automation degree and realizing continuous automatic operation from paddy feeding to finished rice packing;

5. Rice milling speed is fast, the complete set of equipment has a daily output of about 25 tons;

6. The structure is neat and beautiful, and the energy consumption is low. The operation and maintenance are convenient, and the disassembly and assembly of all equipment are very convenient;

7. The rice milling part of the equipment adopts negative pressure rice milling technology, which has low rice temperature, no chaff, and fewer broken rice rate;

8. Our processing technology: Optical fiber cutting, CNC bending, CNC machine tools, spraying process, high-position spray baking, etc;

9. According to the requirement of the crafting flow, “one” arrangement, the main operations are concentrated in the middle, convenient to operate;

10. High-strength vibration-absorbing bearing configuration, the machine body moves smoothly, is firm and reliable, has low vibration, low noise, and low dust;

Rice Mill Machine Application

25 tons per day parboiled rice mill is popular in Nigeria for processing rice in farmlands, towns, grain shop and specialized households, Little investment, high production efficiency and high profits!

Project Cases

Products Packing and Shipping

Hot Searches