NaN / 0

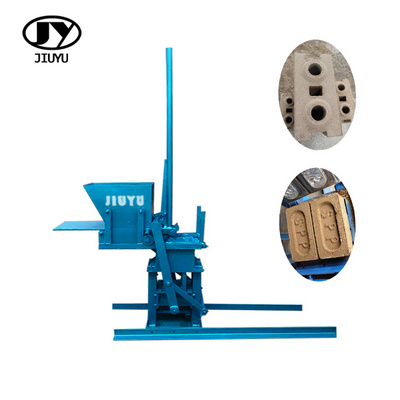

Interlocking Laterite Manual Clay Brick Block Making Machine

Get Latest Price

US$ 2201

≥1 Sets

Quick Details

Type:

Hollow Block Making Machine, Paving Block Making Machine, Interlock Block Making Machine, Curbstone Block Machine, Autoclaved aerated concrete block (AAC)

Brick Raw Material:

Clay

Production Capacity (Pieces/8 hours):

5760 pcs/8hours, 1500 pcs/8hours, 12000 pcs/8hours, 3200 pcs/8hours

Brick size:

400*100*200 mm, 400*120*200 mm, 200*100*60 mm, 300*150*100 mm, 400*150*200 mm, 240*115*90 mm, 200*200*60 mm, 400*200*200 mm, 230*220*115 mm

Product Details

Product Description

|

BLOCK MACHINE

|

CONVEYOR BELT

|

500 MODEL MIXER

|

|

Productivity: 2000-12600pcs/8hours

|

WIDTH:600MM

|

DIMENSION: 3620*2215*3985

|

|

Overall size: 1580*1100*2100

|

LENGTH:8M

|

WEIGHT: 1240kg

|

|

Board Size: 900*450*30

|

POWER:3KW

|

POWER: 10.5kw

|

|

Weight: 810KG

|

WEIGHT: 500KG

|

Diameter: 1.5M

|

Description

Manual hollow block making machine is mechanical equipment, which is used of raw materials to carry out the scientific ratio, add water and mixing. The brick making machine can pressure highly cement brick, hollow block and colorful road brick, which need not sintering and can use with short time drying. It possess the features of simple operation,low investment and large-scale production and is one of the ideal models in current market, so it is the first choice to customer

Main Features

1).Changing the domestic reducer demoulding practice, this machine adopt the pulley, chain sprocket mold release, so it posses advantages of simple structure, durable, safe and reliable, convenient maintenance, no speed reducer leakage phenomenon and save the power.

2).In addition to the frame itself, the whole machine suspension and connection parts should be used in spring and technology of manual pressure vibration to ensure the product's high density and uniformity, smooth operation and low noise.

3).Press head can move vertically, easy to facilitate loading, maintenance and washing, and falling distance of pressure head is small. On the one hand, the gap between presser foot and boxes is small, block without burrs. On the other hand, the damage is small to box core.

4). Bottom pallet in molding vibrates with box core, and are not affected by the impulse force, so pallet life is more than double for the same products.

2).In addition to the frame itself, the whole machine suspension and connection parts should be used in spring and technology of manual pressure vibration to ensure the product's high density and uniformity, smooth operation and low noise.

3).Press head can move vertically, easy to facilitate loading, maintenance and washing, and falling distance of pressure head is small. On the one hand, the gap between presser foot and boxes is small, block without burrs. On the other hand, the damage is small to box core.

4). Bottom pallet in molding vibrates with box core, and are not affected by the impulse force, so pallet life is more than double for the same products.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Block moulds

It adopts excellent steel, which is precise size, smooth surface, reasonable structure, high production efficiency, easy

automation, high life time and low cost.

automation, high life time and low cost.

Hollow block samples

Paver block samples

Kerbstone samples

The Operation Processing of block machine

The produce process of moulds

Specification

Related Products

Hot Searches