NaN / 0

Silicone Duckbill Breast Pump Valve

Get Latest Price

US$ 0.4

≥500 Pieces

Quick Details

Processing Service:

Moulding, Cutting

Place of Origin:

Fujian, China

Brand Name:

OEM

Model Number:

OEM

Product Details

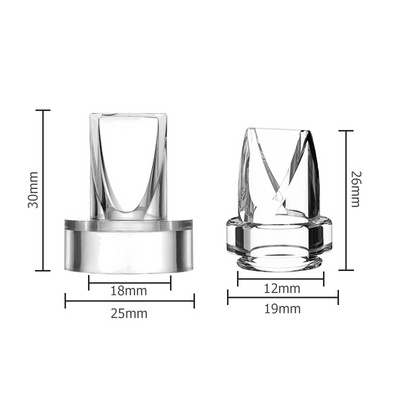

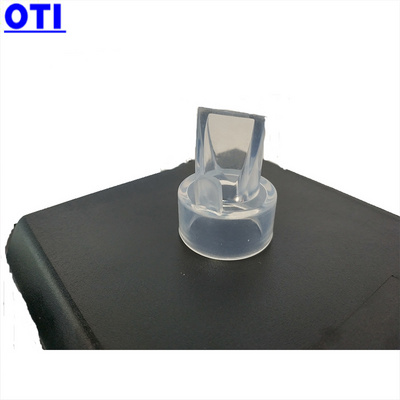

| Item | Silicone Duckbill Breast Pump Valve |

| Material | LSR |

| Size | Standard size or customized size based on customer's requirement |

| Color | Refer to pantone card number |

| Hardness | 30-80 shore A or as required |

| Technology | printing, embossed, debossed, laser etched, epoxy coating, PU coating, hand feel oil spray |

| Feature | Smooth,eco-friendly ,durable and long-lasting,Water-resistance,heat resistance,non-toxic,non-allergic,non-corrosiveness,abrasion resistance ,dust-proof |

| Application | Widely used in breast pump and other vacuum occasion. |

As the leading rubber plastic manufacturer,OTI is engaged in total solution from tooling to finishing in the field of silicone rubber, elastomer and LSR for more than 21 years.

Our advanced facilities include:

(1) 20 sets of compression molding machines which maximum pressure is 300 metric tons.

(2) 6 sets of LSR injection molding machine (The maximum production dimension is 0.10 mm and maximum pressure is 160 metric tons.

(3) 10 sets of plastic injection molding machines, include 4 sets 2K injection molding machines.

(4) 5 sets of EDM machines (side-discharging is available) for tool work.

(5) 5 sets of CNC machines and computerized machining machines for tool work.

(6) Painting and Printing workshop.

Our Tool Advantages:

(1) Steel material mold

(2) Press about 2 millions times, can be used 5-7 years

(3) Strict tolerance of size

(4) Providing 3d drawing based on sample or 2d drawing

(5) Tooling cost can be refunded after reaches the settled quantity

Hot Searches