NaN / 0

Supplier low price gold shaking table 6s small mini Lab shaker Table for mining

Get Latest Price

US$ 1800

≥1 Sets

US$ 1650

≥10 Sets

Quick Details

Production Capacity:

Above 98%

Place of Origin:

Henan, China

Brand Name:

XKJ

Voltage:

220V/380V or other

Product Details

Product Description

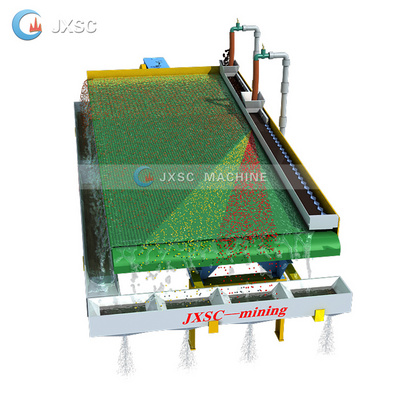

Shaking table Description

The ore are fed from the feeding ore port in the corner of the bed,at the same time supply of lateral flush water to the feed water port.Thus, the ore particles are subjected to gravity, lateral flow, and the inertia and friction generated by the reciprocating asymmetric motion of the bed,Layered by specific gravity and particle size.And along the bed for longitudinal movement and horizontal movement along the inclined bed.The material is finally divided into concentrates, middle ore and tailings.

Shaking table Application

The Shaker Table is also widely used in separation for Gold, Silver, Tin, Columbium, Tantalum, Titanium, Barium, Tungsten, Iron, Chrome, Manganese, Zircon, Lead, Zinc, Mercury, Copper, Aluminum, etc. The shaker effective recycling granularity scope is 2-0.22 millimeters.

Shaking table working principle

The working principle of Shaking Table is to use the combined action of the specific gravity difference of sorted minerals, alternating movement of bed surface, and transverse oblique water flow and riffle (or notch groove), to allow loose layering of ores on the bed surface and fan-shaped zoning. Then different products can be produced.

( 1) Feed ore port (9)Horizontal support

(2) Stroke adjusting device (10)Horizontal adjustment wheel

(3) Ore feeding trough (11)Table support

(4) Feed water port (12) Knife-type support

(5) Water feeding through (13)Stand

(6) Table surface (14)Shaking table head

(7) Concentrate side (15) Motor support

(8) Tailings side (16)Swing Adjusting device

Performance parameters of Shaking Table

| Model | 6-S/LY | |

| Bed size (mm) | 4520x1850x1560mm | |

| Bed surface area(square meter) | 7.67 | |

| Feeding size(mm) | Coarse sand | 1-2.5mm |

| Fine sand | 0.8-1.2mm | |

| Clean water | 0.3-0.6mm | |

| Processing capacity(t/h) | 0.5-3.5 | |

| Stroke | 8-36 | |

| Red times | 240-380 | |

| Lateral inclination | 0-5 degree | |

| Motor | Power(kw) | 1.1 |

| Speed(r/min) | 1400 | |

| Triangle section | A-2000 | |

| Dimensions | 5630x1850x900mm | |

| Weight | 650kg | |

Packaging & Shipping

Packing:

Small models packed in the wooden boxes, big models nude, wearable parts and motors packed in the wooden boxes.

Hot Searches