NaN / 0

Small bottle nail polish filling capping machines.

Get Latest Price

US$ 9000

≥1 Sets

Quick Details

Machinery Capacity:

12000BPH

Packaging Material:

Glass

Filling Material:

Other

Filling Accuracy:

±1%

Product Details

Small bottle nail polish filling capping machines.

Product Description

Small bottle nail polish filling capping machines.

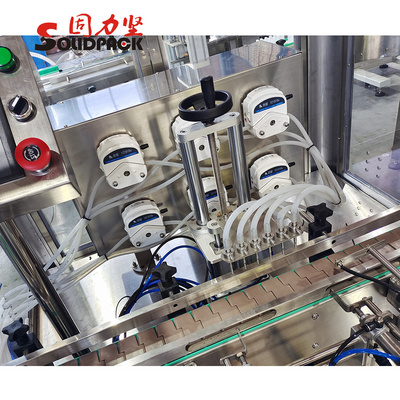

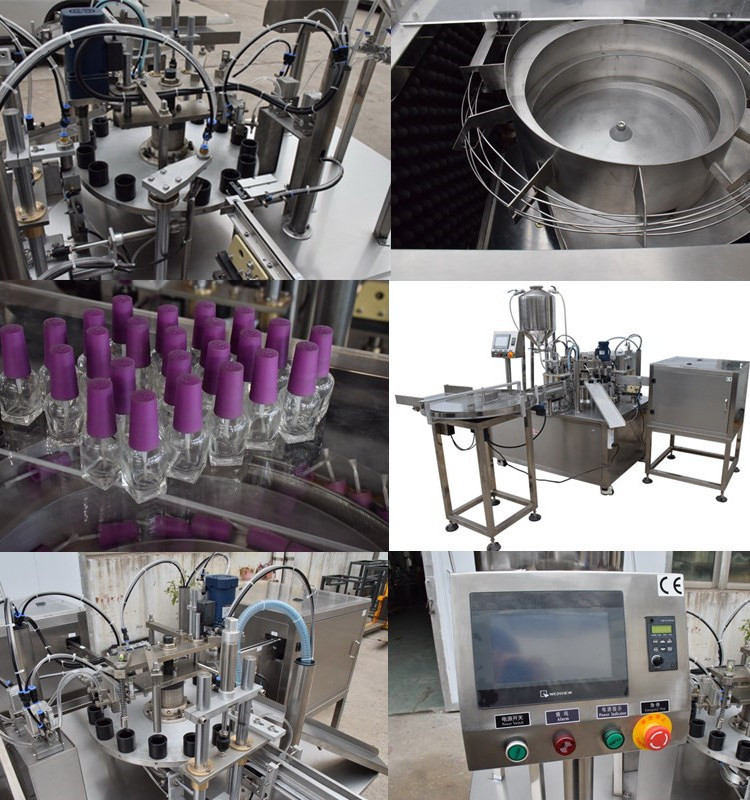

kPSG-3 is widely used in pharmacy, food, cosmetics industry, such as shampoo, moisturizing water, edible oil, pharmacy liquid. Our machine uses exclusive mechanical hand and the leading system to ensure the cap sit in the right position and realize a full automation.

Technical parameters for Small bottle nail polish filling capping machines.

|

Model |

KPSG-3 |

|

Power Supply |

220V/50Hz/single phase |

|

Power Rate |

2.5KW |

|

Air pressure |

0.2-0.4MPa |

|

Filling Range |

0-150g |

|

Filling nozzle |

1 nozzles |

|

Filling Precision |

≤±1percent |

|

Filling capacity |

40pcs/min |

|

Bottle diameter |

Φ10~(mm) |

|

Dimension |

1400mm×900mm×1600mm |

|

Weight |

380kg |

Working process of KPSG-3

ss Step 1 . Bottle are put into the mould seat automatically

Ss Step 2. The machine will fill the bottle automatically

St Step 3 . The machine will feed and screw the caps automatically

Step 4 . Finishing cap screwing, the bottle exit from seat automatically

Eatures and Performance of KP SG-3

1. The machine structure is fully mechanical which ensures a high working speed and steady operation, reducing the failure rate greatly.

2. The machine is fully automatic from bottle feeding to finished bottle exit

3. PLC controller. The operation system is more steady

4. Vibrating disks are applied to deliver bottles and caps in order.

5. Specialized motor is used for cap screwing. The thickness is set properly

6. The production capacity can be realized and control led automatically .

7. Speed shall be adjustable by converter and normal speed is around 40pcs/min

8. High quality stainless steel panel

9. Human-machine interface with direct display and control.

10 The automatic mark detecting the bottles. It will fill when detecting the bottle, if no bottle, the material will not flow.

11 Before bottle exit station, there is another detector. When it checked the the cap screwing is finished, the bottle will exit automatically. If the cap-on and cap screwing fails, the machine will stop as a signal to prevent a waste of material and sprinkle.

KPSG-3 also used for super glues filling in plastic bottle and cap closing, the main products are 502 glue,AB glue, white glue and instant glue etc.

Click here to send a inquiry for details!

Hot Searches