NaN / 0

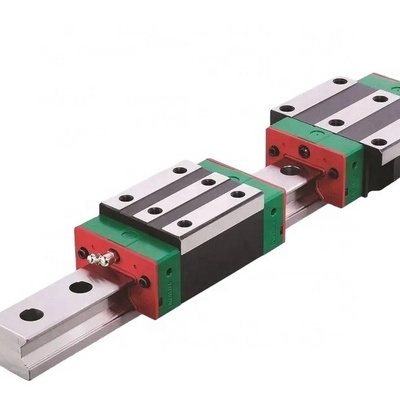

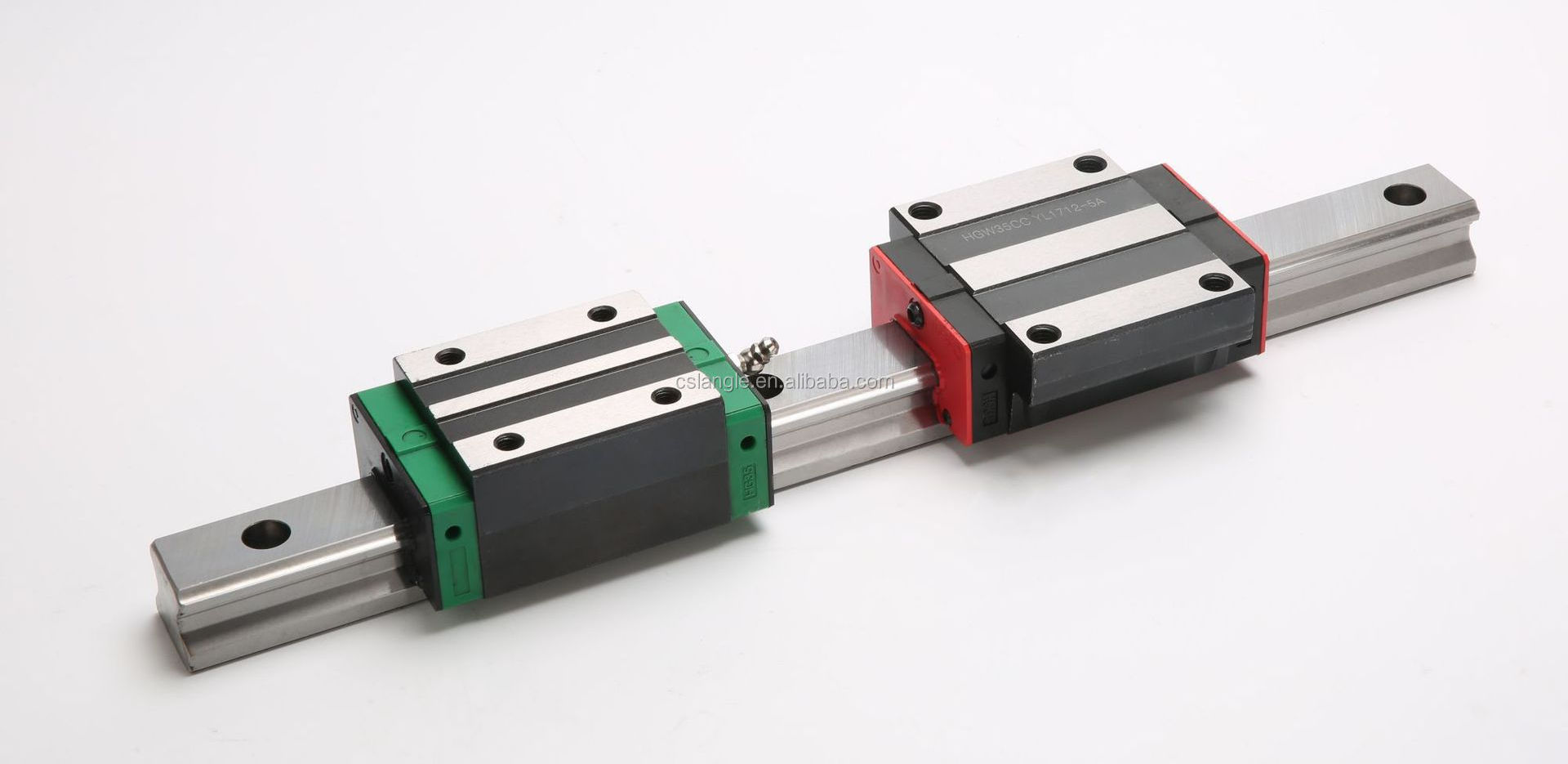

Heavy load linear guide rail set HGR20 HGR25 HGH20CA linear guide rail

Get Latest Price

US$ 15

≥100 Meters

US$ 10

≥20000 Meters

Quick Details

Model Number:

HGR20 HGR25

Place of Origin:

Hunan, China

Brand Name:

OEM, oem

Material:

GCr15

Product Details

Heavy load linear guide rail set HGR20 HGR25 HGH20CA linear guide rail

HGR20 HGH20CA HGH20CC heavy load linear guide rail set

Product Description

| Product name | HGR20 HGH20CA HGH20CC heavy load linear guide rail set |

| Type | linear guide rail set |

| Accuracy | C,H,P |

| Applincation | cnc machine |

| Material | GCr15 |

HG series linear motion guide rail are designed with load capacity and rigidity higher than other similar products with circular-arc groove and structure

optimization. It features equal load ratings in the radial, reverse radial and lateral directions, and self-aligning to absorb installation-error. Thus, HIWIN HG series linear guideways can achieve a long life with high speed, high accuracy and smooth linear motion.

Features

(1) Self-aligning capability By design, the circular-arc groove has contact points at 45 degrees. HG series can absorb most installation errors due to surface irregularities and provide smooth linear motion through the elastic deformation of rolling elements and the shift of contact points. Self-aligning capability, high accuracy and smooth operation can be obtained with an easy installation.

(2) Interchangeability

Because of precision dimensional control, the dimensional tolerance of HG series can be kept in a reasonable range, which means that any blocks and any rails in a specific series can be used together while maintaining dimensional

tolerance. And a retainer is added to prevent the balls from falling out when the blocks are removed from the rail.

(3) High rigidity in all four directions

Because of the four-row design, the HG series linear guideway has equal load ratings in the radial, reverse radial and lateral directions. Furthermore, the circular-arc groove provides a wide-contact width between the balls and the

groove raceway allowing large permissible loads and high rigidity

Hunan Langle Technology Co., Ltd was founded in 2013, we are the China manufacturer focus on building systems for industrial applications, non-standard automation, workstations, machine guards, Stairs & Platforms, Metal Fence, Display rack, etc.

Firstly, Langle can offer a full range of services - product design, manufacturing, stocking, and delivery on time which enable us to be your “one-stop” shop for improving your systems and your ideal space on controlling cost and providing more efficient working projects.

Secondly, Langle can offer the OEM/ODM service for customized aluminum extrusions according to customer's request, we were owned several large type extrusion machines (size at 800 tons, 1800 tons, 2500 tons, 3600 tons etc.) and other production lines include oxidizing, battery, flame-plating, sand-blasting to support.

1. Rich experiences in industrial Aluminium Profile Application for Automation (15 years);

2. Mass available stock for a fast shipping to whole the world;

3. NO MOQ , even 0.5 meter can be acceptable;

4. Supply both aluminium profiles & related accessories to save your time on resourcing;

5. Welcome your CUSTOMIZED design, OEM acceptable;

6. Offer professional services from tooling design, extrusion production, assembling, cutting, drill threading till packaging. NEVER worry about quality and deadline.

Langle is the team full of vitality and unlimited creativity, we are like family members, joint efforts, friendship and mutual assistance, for our common goal to struggle together.

We are keep growing and goal of becoming the leader of industry, and constantly improving our system is our continuous progress.

Aluminum in general, and aluminum extrusions in particular, offer a number of benefits relative to alternative materials and processes. Aluminium extrusion is often the most viable solution that meets the specific manufacturing needs of design flexibility, cost savings, product performance, and shorting design and assembling time.

The Advantage extrusion aluminum profile are included Lightweight, Strong, High in strength-to-weight material, Resilient, Corrosion resistant, Excellent thermal conductors, Non-sparking, Excellent electrical conductors, Non-magnetic, Noncombustible & Nontoxic, Reflective, Seamless, Easily tailored, Quick-to-market, Easy to fabricate & assemble, Sustainable.

Langle can help you choose the appropriate alloy and design the optimum extrusion profile for your project and budgetary requirement, and associated accessories are available as well to save your time to resource it.

1. Saving mould cost and shorten production time;

2. Shorting design and assembling time;

3. Associated accessories are available as well to save your time to resource it;

4. Controlling cost and providing more efficient working project;

5. Improving your systems and space management with our professional technical team.

Aluminium Extrusions can be found in a wide range of applications, they have standard aluminium profiles, and Non-standard extrusion alumininum profiles.

Standard aluminium profiles:

It is widely used on Frame system, Assembly line, Conveyors, Workbench, Machine Guards, Stairs & Platforms, Metal Fence, Display rack, Automotive, Motor aluminium housing, Bridge system, Vessel, Elevator, 3D Printers, CNC Engravers, Non-standard Automation, Hot Wire Machines, Automation, Laser Cutters, Camera Sliders, Workbench or Worktable, Robotics, Machine frames, Machine guards, etc.

Non-statndard extrusion aluminum profiles:

-

High conductivity of heat and electricity, radiators, heatsinks, air conditioning, electronics, building systems, precision tubing, flat extrusion profiles, complex extrusion profiles, Cooling system.

-

Low weight to high strength ratio, railway stock, aeronautical, marine, automotive.

-

Corrosion resistance, marine, mining, cables, architectural, military, and wires.

We offers service from tooling design for customized project, extrusion production, assembling, cutting, drill threading till packaging, give assistance for our customer to develop the new style and functional products.

Packaging details:

Re aluminium profiles with max length of 6 meters, we can cut the length as per your needs, and package in the most suitable way to save your cost and protect the damages from transport.

1. full length of 6 meters profile can be free loaded with container without any pallet or wood frame, you can also add it as you wish.

2. Shorter length like 1~4 meters ship via LCL, the best way is to package with wooden box, you may not save this cost to loss money due risk of damage during transport with bulk shipment.

3. The accessories can be put into the wooden box together with aluminium profile to save space, or pack with cartons if you just order accessories only

Hot Searches