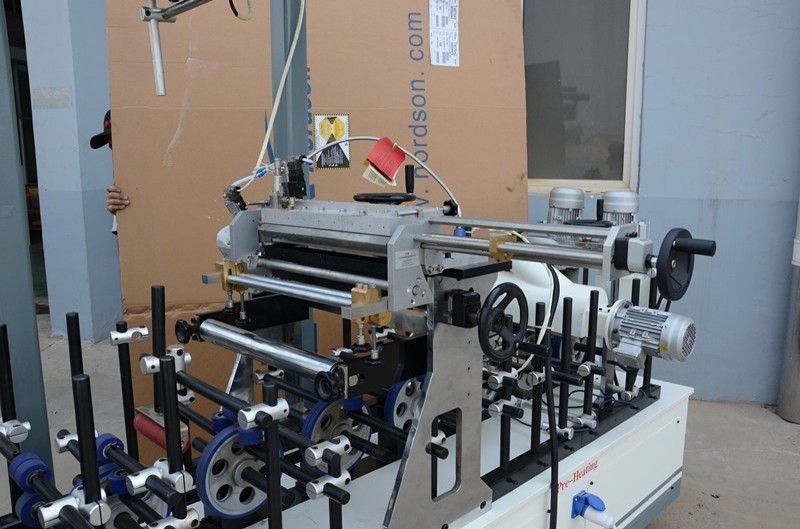

It adopts high precision lip-style glue spreading machine head and uses polyurethane (PUR) glue. Glue spreading is even, glue distribution can be controlled and adhesive strength is very strong. It is upgraded products of water-base adhesive, solvent base adhesive and hot melt glue wrapping machines.

It can be used to wrap PVC, PP, PET, veneer and paper, and etc on the profile of several of lines. The working efficiency is high and the working speed can be up to 50m/min.

|

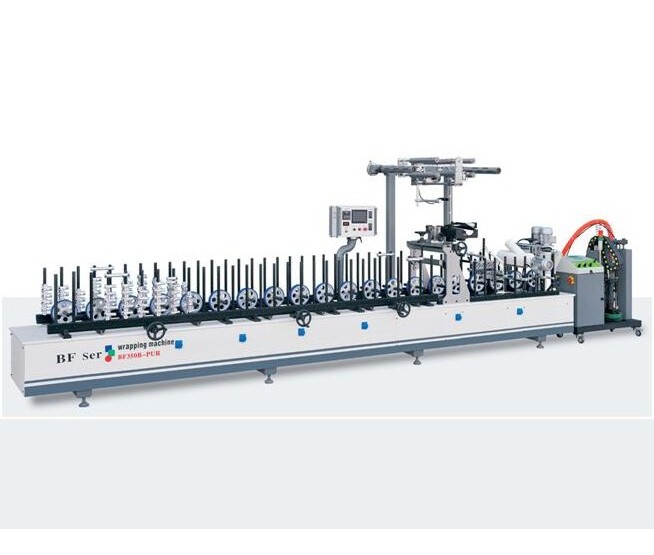

Model

|

BF350B-PUR-II

|

|

Max. wrapping width

|

350mm

|

|

Max processing thickness

|

120mm

|

|

Wrapping speed

|

0-50m/min

|

|

Total Power

|

13Kw

|

|

Power of main motor

|

2.2Kw

|

|

Power of dusting motor

|

0.37Kw3

|

|

Power of PUR glue machine

|

8Kw

|

|

Manner of adjusting width of glue spreading

|

Change gasket of glue spraying head

|

|

Electrical control manner

|

PLC control, Touching screen

|

|

Overall dimension of main machine

|

5780Χ900Χ1900mm

|

|

Overall dimension of glue machine

|

1030Χ420Χ1600mm

|

|

Weight

|

1700kg

|

It doesn't contain water and solvent and the total solids content is 100%. It is a high performance, environment friend polyurethane adhesive and meets the needs of paying more and more attention to environment from home and aboard. It has excellent resistivity against water, heat creep and solvent. Compared ordinary hot melt glue, this reactive polyurethanehot melt glue has excellent comprehensive performance. It not only has feature of solvent less adhesive, strong initial adhesive strength and quick positioning while setup for ordinary hot melt glue, but also has special performance of resistivity against water, heat, cold, creep and medium for reactive polyurethane hot melt glue. The temperature of PUR glue is 120℃ less than the temperature of ordinary glue application,150-180℃

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

|

Plastic Packaging

|

|

|

|

Plastic Packaging

|

|

|