NaN / 0

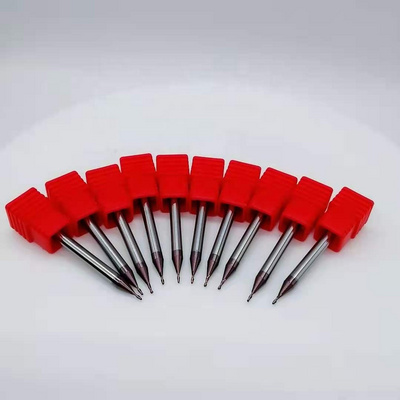

Carbide Tiny diameter endmills Milling Cutter Micro End Mills

Get Latest Price

US$ 2

≥100 Pieces

US$ 1.5

≥500 Pieces

Quick Details

Material:

Carbide

Coating:

AlTiN

Place of Origin:

Hunan, China

Brand Name:

sanstone

Product Details

Recommend Products

Products Description

|

Introduction for common coatings of carbide end mills

|

|

|

|

|

|

|

||||||

|

Grade of endmill

|

Coating composition

|

Color

|

Hardness(Hv)

|

Thickness(μm)

|

Frictional coefficient

|

Maximum working temperature(℃)

|

||||||

|

HRC45 end mills

|

AlTiN

|

black

|

3300

|

1-4

|

0.7

|

850

|

||||||

|

HRC55 end mills

|

TiAlN

|

Bronze

|

3400

|

1-4

|

0.7

|

900

|

||||||

|

HRC60 end mills

|

NaNo TiAlCrN

|

Black

|

4000

|

1-7

|

0.35

|

1100

|

||||||

|

HRC65 end mills

|

NaNo TiAlXN

|

Blue

|

4500

|

1-7

|

0.45

|

1200

|

||||||

|

Special end mills for SS

|

NaNo AlTiN

|

Gold

|

4500

|

1-7

|

0.55

|

1200

|

||||||

|

Carbide Material Introduction

|

|

|

|

|

||||

|

ENDMILL GRADE

|

CARBIDE GRADE

|

GRAIN

|

INTRODUCTION

|

APPLICATION

|

||||

|

HRC45 end mills

|

YG10X

|

0.6μm

|

YG10X is tungsten carbide powder with 89.7% WC and 10% cobalt powder, and has high toughness and wear resistance.

|

Carbon steel

Alloy steel

Cast iron

Pre hardened steel with hardness lower than HRC40.

|

||||

|

HRC55 end mills

|

YL10.2

|

0.5μm

|

YL10.2 is ultra fine grain and containes Ni and Cr element, which provides high strength and good toughness.It is widely used in the manufacture of end mills and drills

|

General Steel

Stainless Steel

cast iron

Pre hardened steel with hardness lower than HRC50.

|

||||

|

HRC60 end mills

|

WF25

|

0.4μm

|

WF25 is 0.4micron ultrafine carbide powder and provides very high toughness and wear resistance.

|

High Hard steel, staniless steel,cast iron, etc

It is recommended to be used for various materials with hardness lower than HRC58

|

||||

|

HRC65 end mills

|

GU25UF

|

0.4μm

|

GU25UF is 0.4micron powder with 12% cobalt and has very high toughness and wear resistance.It is the most suitable for hard

cutting.

|

High hardness steel

Heat treated steel

Ductile iron

And other materials with hardness HRC50-HRC65

|

||||

|

Special end mill for SS

|

WF25

|

0.4μm

|

WF25 is 0.4micron ultrafine carbide powder and provides very high toughness and wear resistance.

|

Stainless steel

carbon steel

alloy steel

titanium alloy

heat-resisting alloy

|

||||

Working Video

Company Introduction

Contact Us

FAQ