NaN / 0

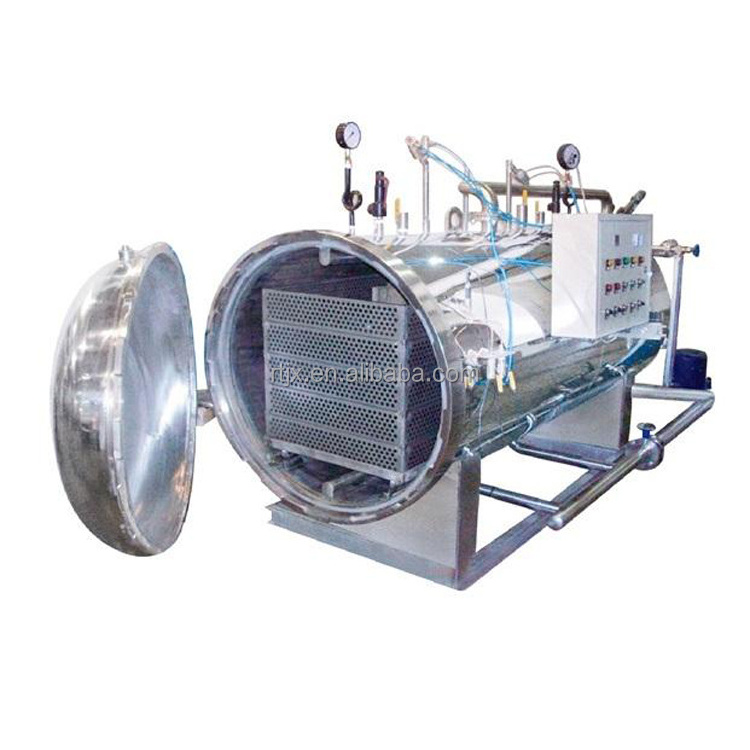

Horizontal Spray Sterilization Machine For Long Shelf Food Can / Pouch Retort For Sale Suppliers

Get Latest Price

US$ 15000

≥1 Sets

US$ 14000

≥2 Sets

Quick Details

Place of Origin:

Shandong, China

Brand Name:

Ritong

Voltage:

380V, 220V, customized

Power:

customized

Product Details

Horizontal Spray Sterilization Machine For Long Shelf Food Can / Pouch Retort For Sale Suppliers

Product Description

Food retort pouch machine

Equipment features

• Reduce steam consumption, steam and atomizing sterilizing water make thermal mixing in retort directly, which increases speed of temperature rise and drop.

• Few quantity of processing water makes quick cycle, and reaches presetting sterilizing temperature quickly.

• Water jets from different angles, steam, air and water mix, make convection and form perfect temperature distribution.

• Have low noise, and create quiet and comfortable operational environment.

• The retort equips four movable temperature sensing probes, which can monitor F value of food center and thermal distribution situation in retort, and know

thermal penetration (the time to reach food geometrical center from food surface)at any time.

• Have perfect pressure control, pressure of the whole

production process makes continuous adjustment so

as To suit change of pressure in product

packing, and to make deformation of

product packing to the minimum,

especially suit product with gas

packing.

• Process water preheating system (option) can ensure product with heat preservation and thermal filling has sustainable temperature rise process.

• Sterilizing water uses softening water (option), which avoids outside packing pollution and dirt caused by process water quality problem.

• Steam sterilizing function (adjustable).

Application

|

MODEL |

DIAMETER |

CYLINDER LENGTH |

TOTAL LENGTH |

PRODUCTIVITY |

BOILER MODEL |

CAPACITY |

|

700 |

0.7 |

1.2 |

1.7 |

120-150kg |

0.1 |

0.7 |

|

800 |

0.8 |

1.5 |

2.3 |

200-250kg |

0.2 |

0.9 |

|

900 |

0.9 |

1.8 |

2.5 |

300-350kg |

0.2 |

1.1 |

|

1000 |

1 |

2.2 |

3.0 |

500-550kg |

0.3 |

1.8 |

|

1200 |

1.2 |

3 |

3.8 |

800-1000kg |

0.5 |

4.0 |

|

DISPOSE |

|

|

700( ELECTRIC&STEAM , 30kw ) |

WITH 3 TRAYS , 1 PALLET , 1 TROLLEY |

|

800( ELECTRIC&STEAM , 36kw ) |

WITH 6 TRAYS , 2 PALLETS , 2 TROLLEIES |

|

900( ELECTRIC&STEAM , 45kw ) |

WITH 8 TRAYS , 2 PALLETS , 2 TROLLEIES |

|

1000( ELECTRIC&STEAM , 60kw ) |

WITH 10 TRAYS , 2 PALLETS , 2 TROLLEIES |

|

1200( ELECTRIC&STEAM , 90kw ) |

WITH 15 TRAYS , 3 PALLETS , 3 TROLLEIES |

|

1500 |

WITH 20 TRAYS , 4 PALLETS , 4 TROLLEIES |

More photos

Fitting parts of the retort pouch machine

Packaging & Shipping

We will delivery your goods by LCL/20' FCL/40'FCL depending on your order. Before delivery, our professional engineer will do trial run for each machine to check and confirm everything is workable, you also can come to our factory for testing together with us.when loading, our workers will fix the machine tightly in the container to ensure the safety in the transportation.

Our Services

Service & Installation

a.) Consultation service before, during, and after sales; b.) Project planning and design services;

c.) Debugging of equipment until everything is functional;

d.) Management of equipments' long distance shipping from seller's factory to named place by buyer;

e.) Training of equipment maintenance and operating personally;

d.) New production techniques and formulas;

e.) Provide 1 year complete warranty and life-time maintenance service.

FAQ

FAQ

Q : What’s the delivery term for making business with us?

A: FOB, CFR & CIF optional; It’s mainly depend on client’s requirement;

Q: Do you have machines in stock?

A: Yes, but just the small-scale machines. Machines are different with other products, most of the large-scale machines are designed according to our customers' requirements, different customers have different production requirements, so the technical parameter is different for most machines. On the other hands, most of the our machines will cover a large area, so once the machines are finished, we will effect shipment after QC

Q: What’s the lead time after placing order ?

A :Usually it takes about 25~30 days after we received your deposit.

However, it would depend on our production line schedule(the timing clients place order)and the complication of the item.

We are specialized in retort pouch machine for 20 years

Our equipment can be customized, leave an inquiry to know more details about price, packing, shipping and price.

Certifications

Hot Searches